A hybrid heat release and plugging removal method for carbonate cemented sandstone heavy oil wells

A carbonate and heat release technology, applied in drilling compositions, chemical instruments and methods, earthwork drilling, etc. The effect of liquid and residue flowback, enhanced oil recovery, and increased seepage radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

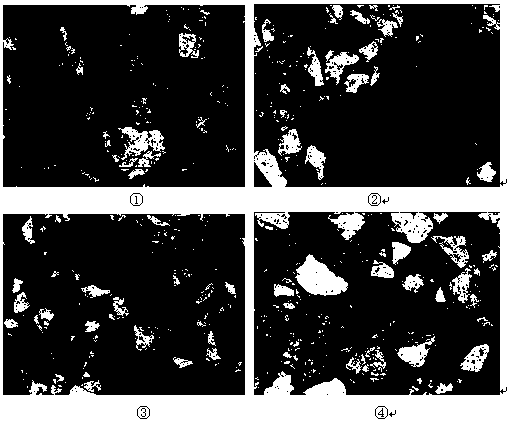

Image

Examples

Embodiment 1

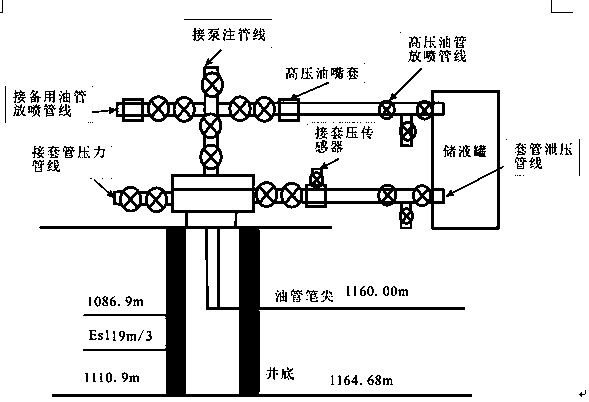

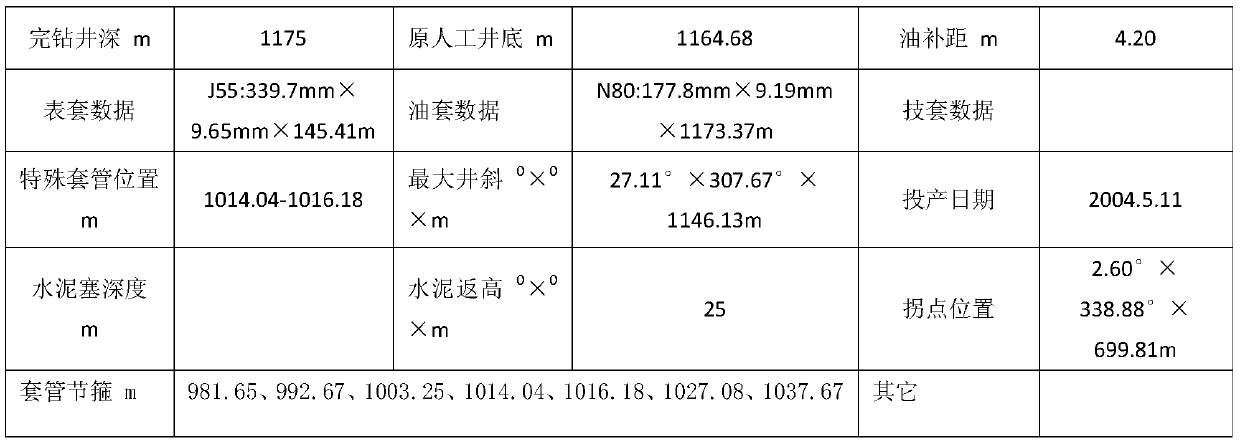

[0037] Example 1: Well G54-X4 acidizing design and implementation effect

[0038] Implementation of acidification transformation layer: Sha 1 member; well section: 1086.9m ~ 1100.9m.

[0039] 1 Basic data of oil wells and basic conditions of acidizing intervals

[0040] 1.1 Basic drilling data, as shown in Table 1.

[0041] Table 1

[0042]

[0043] 1.2 Reservoir data, as shown in Table 2.

[0044] Table 2

[0045] layers Well section m Sand thickness m Permeability 10 -3 μm 2

Actual well section m Actual thickness m Acoustic time difference μs / ft ES11 1086.9-1127.8 40.9 21.754 1086.9-1094 7.1 81-112 ES11 1086.9-1127.8 40.9 21.754 1097.3-1100.6 3.3 85-112 ES11+2 1086.9-1127.8 40.9 21.754 1102.3-1110.9 8.6 58-107

[0046] 2 Operation situation and construction purpose

[0047] 2.1 Operation situation

[0048] The well was put into production for PS sand control on May 11, 2004, and a total of 21.6 cubic m...

Embodiment 2

[0105] Example 2 Mixed heat release and plugging removal method for carbonate cemented sandstone heavy oil wells

[0106] Proceed as follows:

[0107] a. Heating the wellbore (heating for 6 hours) (electric heating) to reduce the viscosity of the heavy oil in the wellbore and near the wellbore (within the radius of the wellbore edge 1-2m);

[0108] b. Inject the pre-fluid (pickling well wall) into the wellbore, and then add the main fluid; the volume of the injected main fluid is 1.2 times the volume of the downhole tubing being replaced;

[0109] The pre-fluid is a light compound amino acid;

[0110] The main liquid is composed of light compound chloro-based acid and heat-releasing polyfluorine plugging agent in a volume ratio of 1:1. Heat-following and heat-peeling oil film attachment, lightly mixed chlorine-based acid slowly acid-dissolves carbonates, prevents large particles of carbonates from dissolving and falling off, causing particles to migrate to form "bridge plugg...

Embodiment 3

[0121] Example 3 Mixed heat release and plugging removal method for carbonate cemented sandstone heavy oil wells

[0122] Proceed as follows:

[0123] a. Heating the wellbore (heating for 8 hours) (closed thermal fluid circulation heating) to reduce the viscosity of the heavy oil in the wellbore and near the wellbore (within the radius of the wellbore edge 1-2m);

[0124] b. Inject the pre-fluid (pickling well wall) into the wellbore, and then add the main fluid; the volume of the injected main fluid is 1.3 times the volume of the downhole tubing being replaced;

[0125] The pre-fluid is a light compound amino acid;

[0126] The main liquid is composed of light compound chloro-based acid and heat-releasing polyfluorine plugging remover in a volume ratio of 0.8:1.2, and the injection method is: alternately inject light compound chloro-based acid and heat-releasing poly Heat-following and heat-peeling oil film attachment, lightly mixed chlorine-based acid slowly acid-dissolves...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com