Sample for testing high-temperature shearing intensity of composite material and method thereof

A composite material and shear strength technology, which is applied in the direction of applying stable shear force to test material strength, analyze materials, strength characteristics, etc., can solve problems such as slow heating rate, insufficient sensitivity of temperature control, and difficult design and test methods , to achieve uniform distribution of temperature field and stress field, simple and easy test method, and avoid internal damage of the sample

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

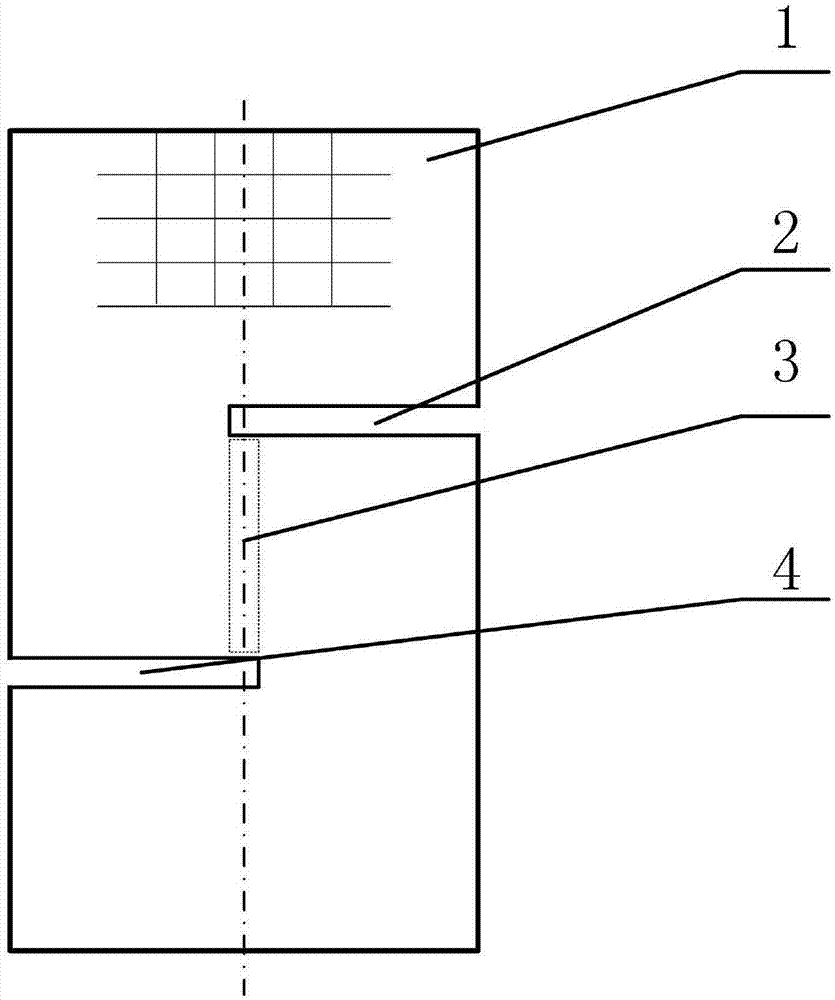

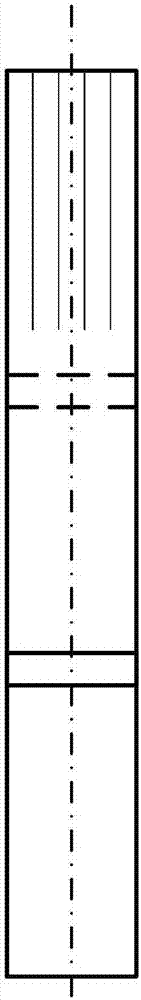

[0050] Specific implementation mode one: as figure 1 , figure 2As shown, this embodiment discloses a sample for testing the high-temperature shear strength of a composite material. The sample is a plate type, and a first notch 2 is provided on the sample near the upper end level, and the upper end of the sample is near the lower end level. A second incision 4 is provided (that is, the incision directions of the first incision 2 and the second incision 4 are both perpendicular to the layer layer and the length direction of the sample), and the first incision 2 and the second incision 4 both run through the sample In the thickness direction, the lengths of the first notch 2 and the second notch 4 are both greater than half of the sample width (preferably the lengths of the first notch 2 and the second notch 4 are slightly greater than half of the sample width), and the first notch 2 and the roots of the second notch 4 are rectangular, and the first notch 2 and the second notch...

specific Embodiment approach 2

[0051] Specific implementation mode two: as figure 1 , figure 2 As shown, this embodiment is a further limitation of specific embodiment 1. The central area between the first notch 2 and the second notch 4 on the in-plane shear sample 1 is an in-plane shear test. Sample gauge length section 3, the width of the in-plane shear sample gauge length section 3 is equal to the horizontal distance between the roots of the first notch 2 and the second notch 4, the in-plane shear sample gauge length section 3 The length is equal to the vertical distance between the lower edge of the first slit 2 and the upper edge of the second slit 4 .

specific Embodiment approach 3

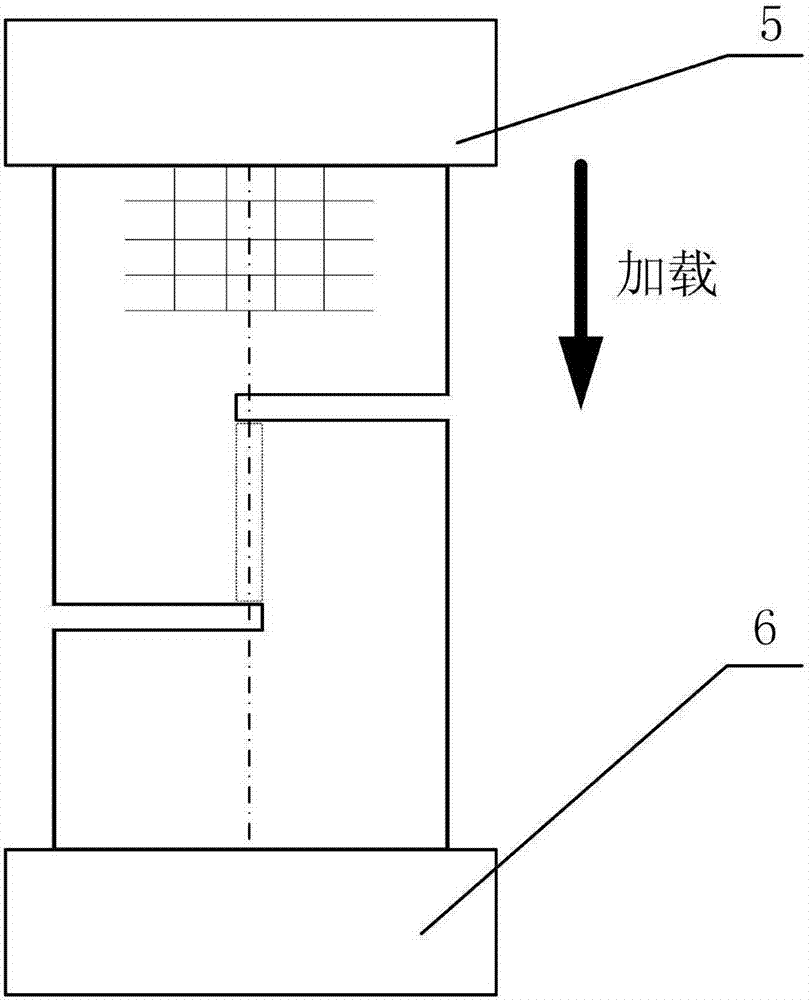

[0052] Specific implementation mode three: as Figure 1-Figure 3 As shown, this embodiment discloses a method for testing the high-temperature shear strength of a composite material using the sample described in Embodiment 2, wherein the method includes the following steps:

[0053] Step (1): Check the appearance of the in-plane shear sample 1 (determine the integrity of the sample, and there is no obvious damage), number and record the surface state of the in-plane shear sample 1;

[0054] Step (2): Before the test, measure the width and thickness of the sample at any 3 places in the gauge length section 3 of the in-plane shear sample with a caliper, and record the data;

[0055] Step (3): The in-plane shear sample 1 is put between the upper indenter 5 and the lower indenter 6 of the testing machine, and the position of the in-plane shear sample 1 is adjusted to ensure that the in-plane shear sample 1 is on, The lower two ends are in contact with the upper indenter 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com