Washing pipe system of dry-method acetylene generator

A dry-process acetylene and generator technology, which is applied in separation methods, chemical instruments and methods, and the use of liquid separation agents, can solve the problems of acetylene gas loss and environmental protection, and achieve the effects of cost saving and on-site environment improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

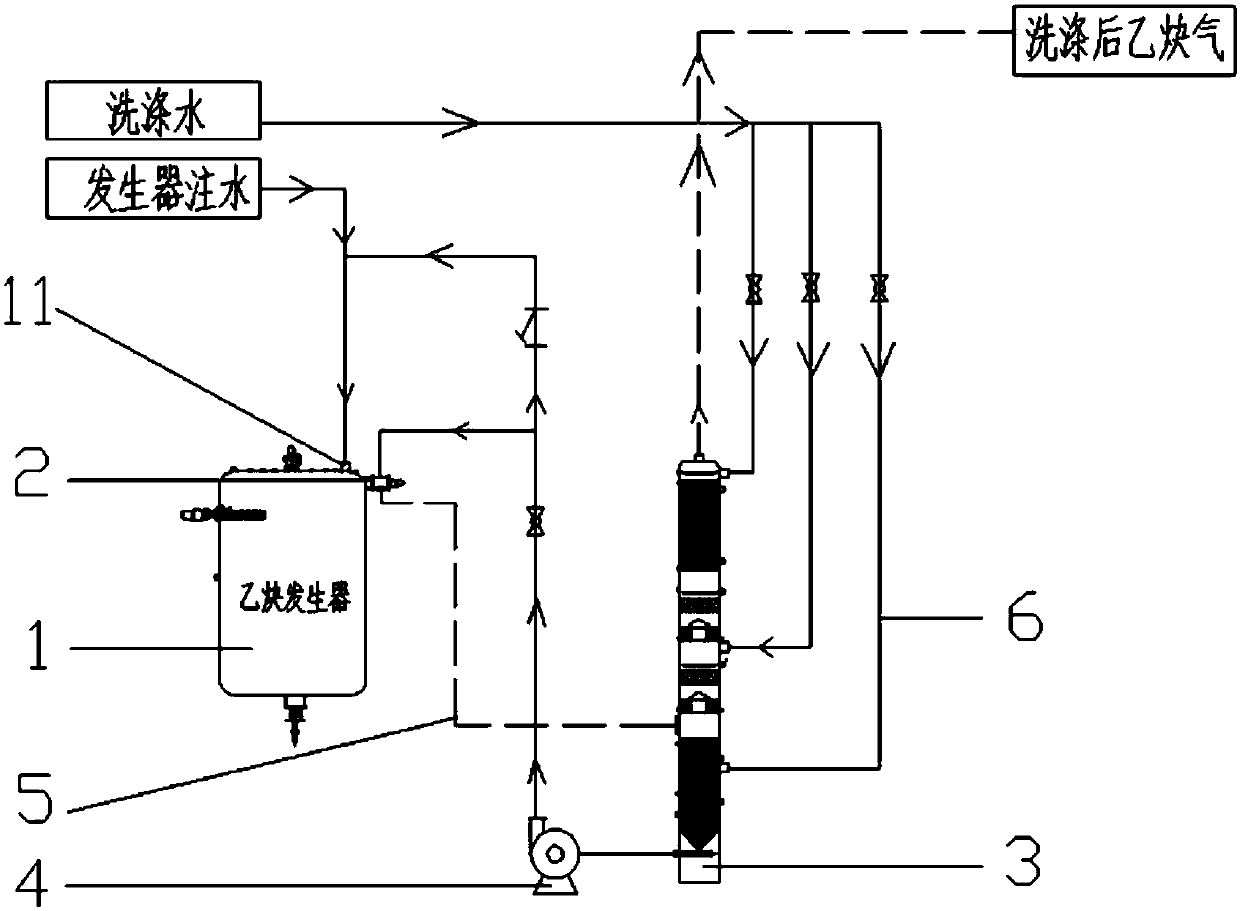

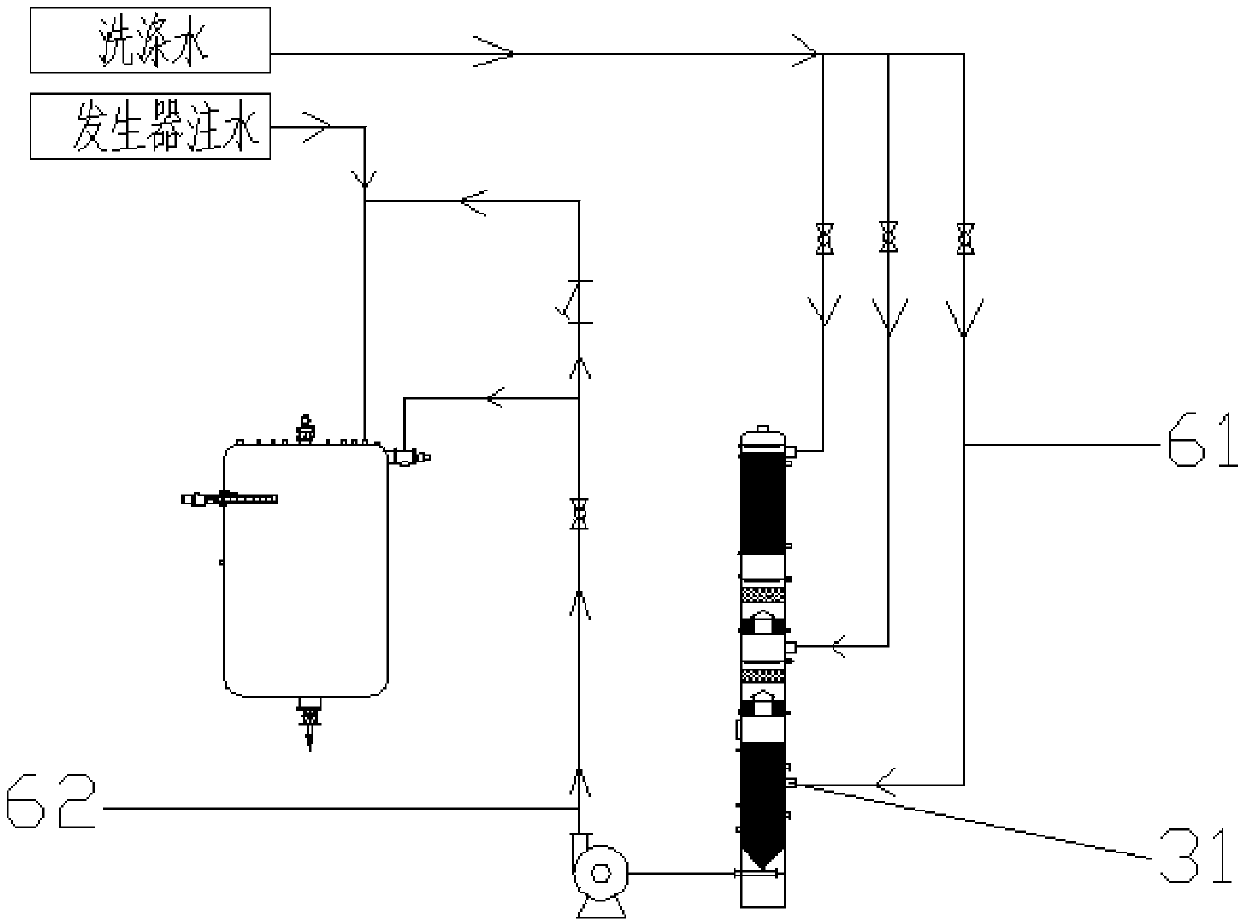

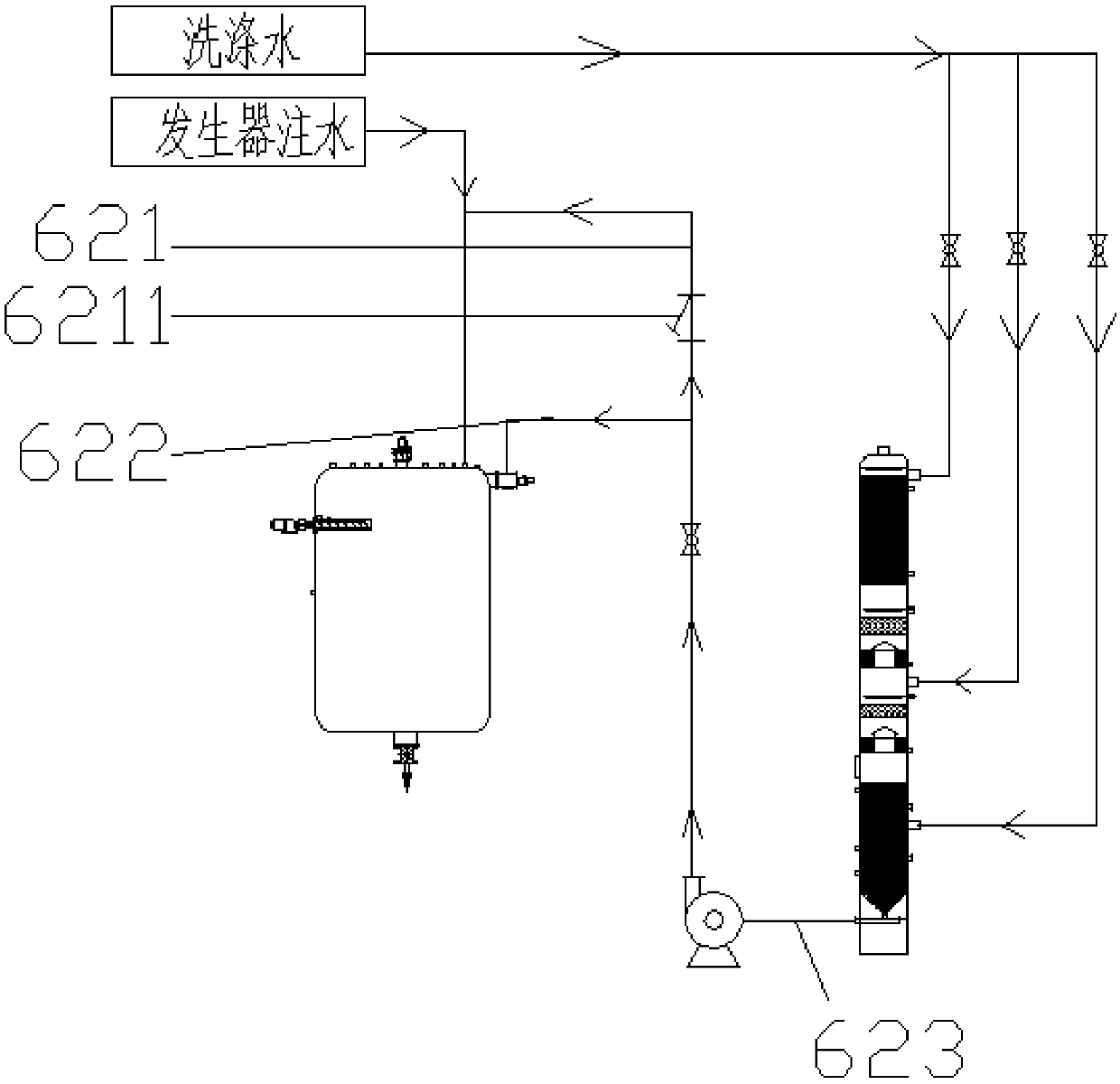

[0040] figure 1 A schematic diagram of the overall structure of the washing water internal circulation system of the dry acetylene generator provided in Example 1; figure 2Structural schematic diagram of the washing water pipeline in the washing water internal circulation system of the dry-process acetylene generator provided in Example 1; image 3 A schematic structural diagram of the washing water recycling pipeline of the washing water internal circulation system of the dry-process acetylene generator provided in Example 1; Figure 4 The schematic diagram of the gas pipeline structure of the dry acetylene generator washing water internal circulation system provided in Example 1;

[0041] Such as figure 1 As shown, a washing water internal circulation system of a dry acetylene generator, the washing water internal circulation system includes a dry acetylene generator 1, a gas phase scraper 2, a washing cooling tower 3, a slag water recycling pump 4 and a gas pipeline 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com