Epoxy-based ionic liquid/multi-walled carbon nanotube/polymer composite material and preparation method thereof

A technology of multi-walled carbon nanotubes and ionic liquids, applied in the direction of organic chemistry, etc., can solve the problems of mechanical properties and processing performance decline, reducing the filling amount of carbon nanotubes, loss of use value, etc., to improve processing performance and electrical performance. , the effect of reducing the amount of filler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] According to the present invention, the preparation method of described epoxy-based ionic liquid preferably comprises:

[0031] Mix epichlorohydrin and N-methylimidazole and react at 30-45°C for 3-5 hours. During the reaction, the color of the solution turns orange-yellow until it turns reddish brown. When the reactant turns reddish brown, it is more Stable, the reaction rate can be accelerated by increasing the temperature. Since the epoxy group is relatively active, a large amount of heat will be released when the ring-opening reaction occurs. In order to avoid the occurrence of the ring-opening reaction, the system temperature cannot be raised rapidly, so segmental heating is used. To control the degree of reaction, it is preferable to raise the temperature by 5°C to 65°C every half hour after the reaction for 3-5 hours, and stop the reaction after keeping the reaction at 65°C for 3 hours. As the reaction time prolongs, The viscosity of the system gradually increased...

Embodiment 1

[0040] The preparation of embodiment 1 epoxy-based ionic liquid

[0041] Measure epichlorohydrin and N-methylimidazole in a molar ratio of 1.2:1, and add them to a three-necked flask at room temperature, N 2 Protected, mechanically stirred, reacted at 45°C for 5h, during the reaction, the color of the solution changed from orange to reddish brown. After 5 hours of reaction, the temperature was increased by 5°C every half hour until 65°C, kept at 65°C for 3 hours, and then the reaction was stopped. As the reaction time prolongs, the viscosity of the system gradually increases. After stopping the reaction, the product was washed repeatedly with ether. Afterwards, the product was recrystallized and purified with acetone, and weighed after vacuum drying to obtain the product epoxy-based ionic liquid with a monomer conversion rate of 83.11%.

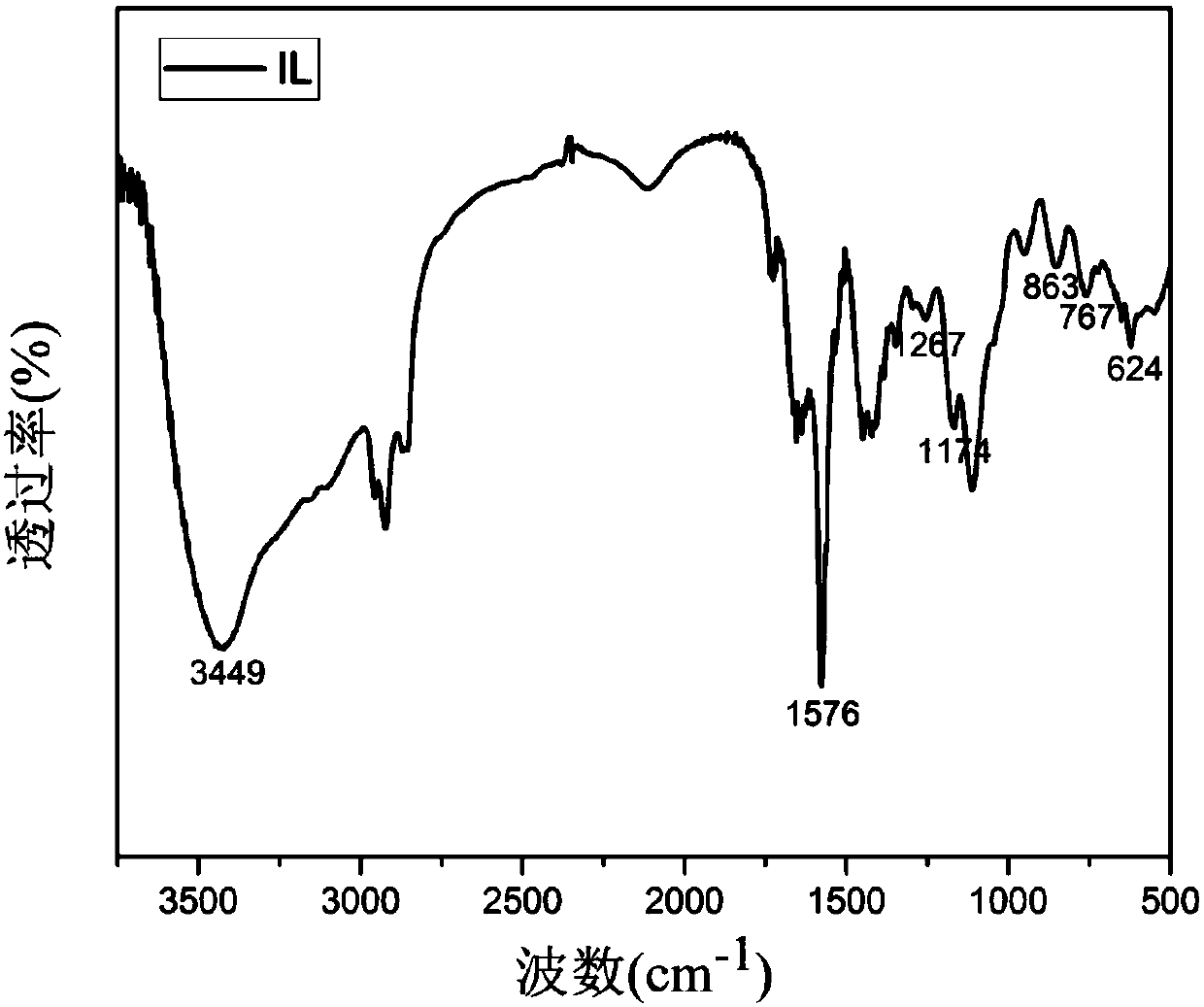

[0042] figure 1 Infrared spectrogram of the epoxy-based ionic liquid prepared in Example 1 of the present invention. figure 1 It shows t...

Embodiment 2

[0043] The preparation of embodiment 2 epoxy group ionic liquid

[0044] Measure epichlorohydrin and N-methylimidazole at a molar ratio of 2:1, and add them to a three-necked flask at room temperature, N 2 Protected, mechanically stirred, reacted at 45°C for 5h, during the reaction, the color of the solution changed from orange to reddish brown. After 5 hours of reaction, the temperature was increased by 5°C every half hour until 65°C, kept at 65°C for 3 hours, and then the reaction was stopped. As the reaction time prolongs, the viscosity of the system gradually increases. After stopping the reaction, the product was washed repeatedly with ether. Afterwards, the product was recrystallized and purified with acetone, and weighed after vacuum drying to obtain the product epoxy-based ionic liquid with a monomer conversion rate of 54.28%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com