Method for correcting deposition errors of broadband anti-reflection films prepared by quartz monitoring method

An anti-reflection coating, broadband technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the difficulty of accurate acquisition and correction of deposition errors, affect the reliability of reverse inversion results, broadband anti-reflection coating Optical characteristics and other issues, to achieve the effect of short cycle, small damage, and reduce serious impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

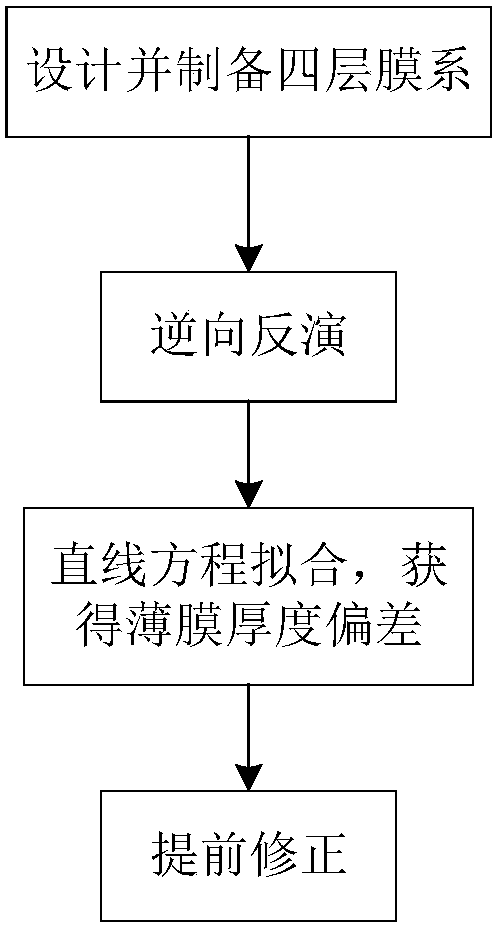

[0036] Such as figure 1 As shown, the present invention provides a method for correcting the deposition error of the broadband antireflection film prepared by the quartz monitoring method, the method comprising the following steps:

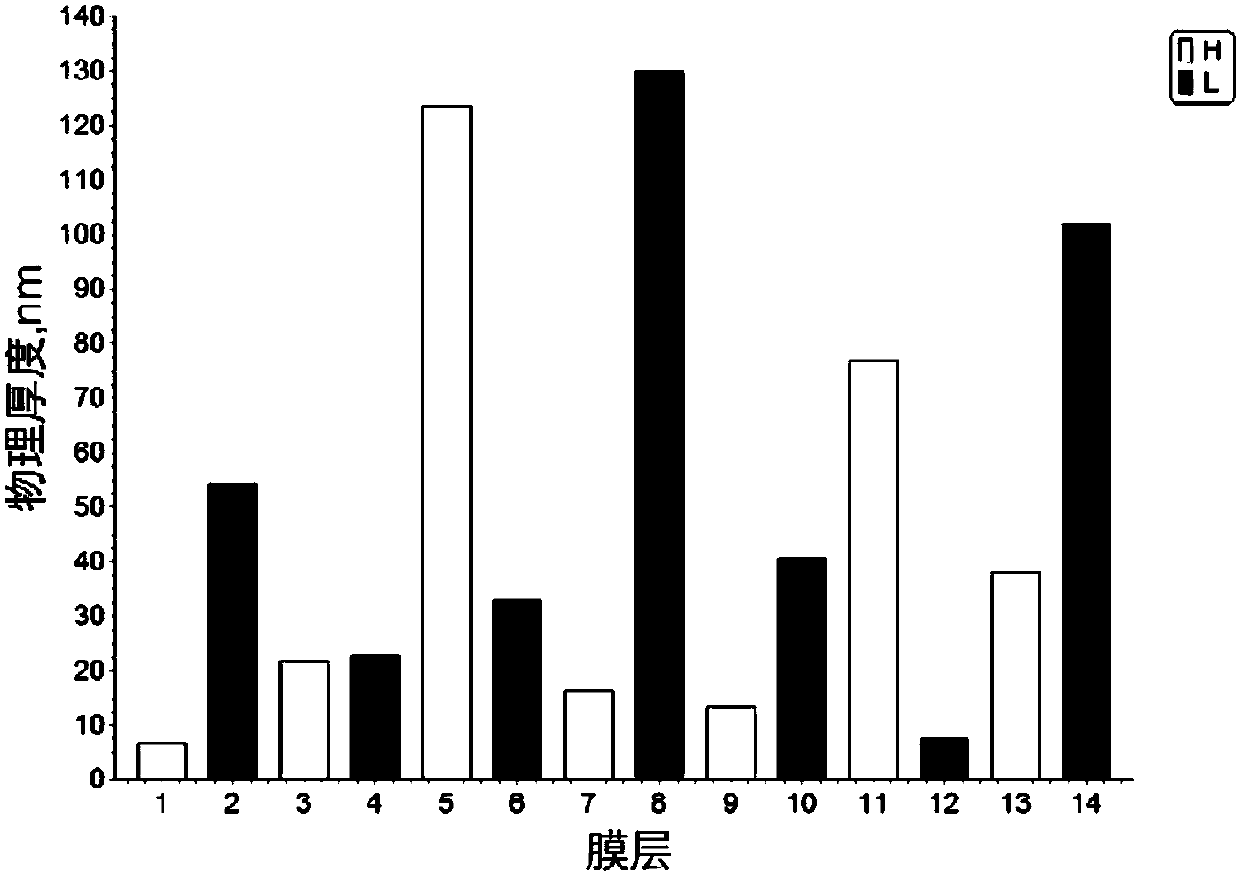

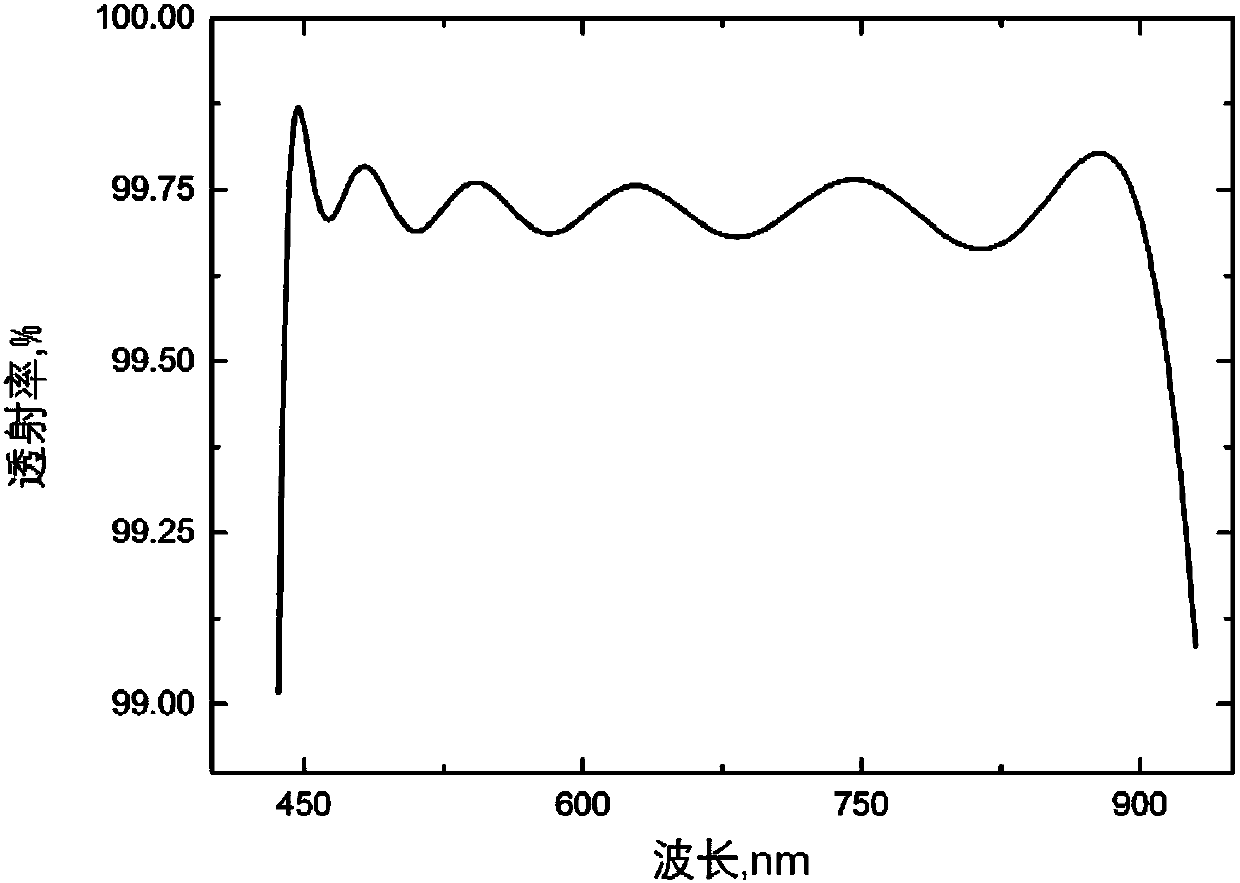

[0037] 1) Design and monitor the thickness. A four-layer film system is plated on the substrate by ion beam assisted deposition process. The four-layer film system includes two-layer films with two thicknesses made of high Two layers of thin films with two thicknesses are produced, and the deposition of the thin films is monitored by a quartz monitor acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com