Automatic waterpower rectifying device for coal seam hydraulic drilling

A deviation correction device and hydraulic technology, applied in directional drilling and other directions, can solve the problems that affect the wellbore ventilation, drainage and energy extraction effect, the bottom of the well cannot reach the predetermined point, and the hazards of underground king-casting work, so as to reduce construction risks, The effect of saving non-drilling time and shortening the drilling cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

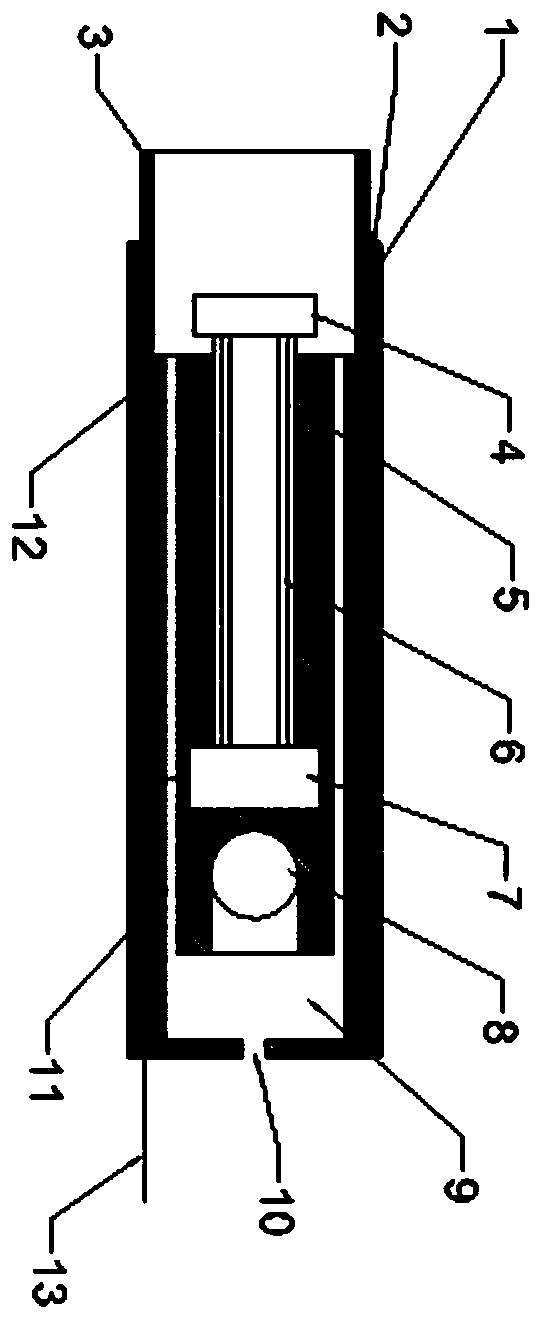

[0023] An automatic hydraulic deviation correction device for coal seam hydraulic drilling, including a casing 1, a drill pipe buckle 2, a positioning sleeve 3, a drill pipe joint 4, a pressure sensor 5, an air cushion 6, a console 7, a hydraulic machine 8, a water storage tank 9, and a water injection inlet 10. The jet channel 11, the jet port 12, and the power cord 13 are characterized in that: a positioning sleeve 3 is installed on the top of the housing 1, and a drill pipe joint 4 is arranged inside the positioning sleeve 3, wrapped by a pressure sensor 5 and an air cushion 6, and the pressure sensor 5 Connect the console 7 with the air cushion 6, and the console 7 connects the hydraulic press 8. The positioning sleeve 3 is also provided with a jet port 12 , which communicates with the water storage tank 9 through the jet channel 11 . The console 7 can control the hydraulic machine 8 to make the water in the water storage tank 9 flow in and out. The console 7 can calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com