Centrifugal type fuel cell air compressor with energy recovery function

A technology of air compressors and fuel cells, which is applied in the direction of fuel cells, liquid fuel engines, electrical components, etc., to achieve the effects of improving efficiency, compact system, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

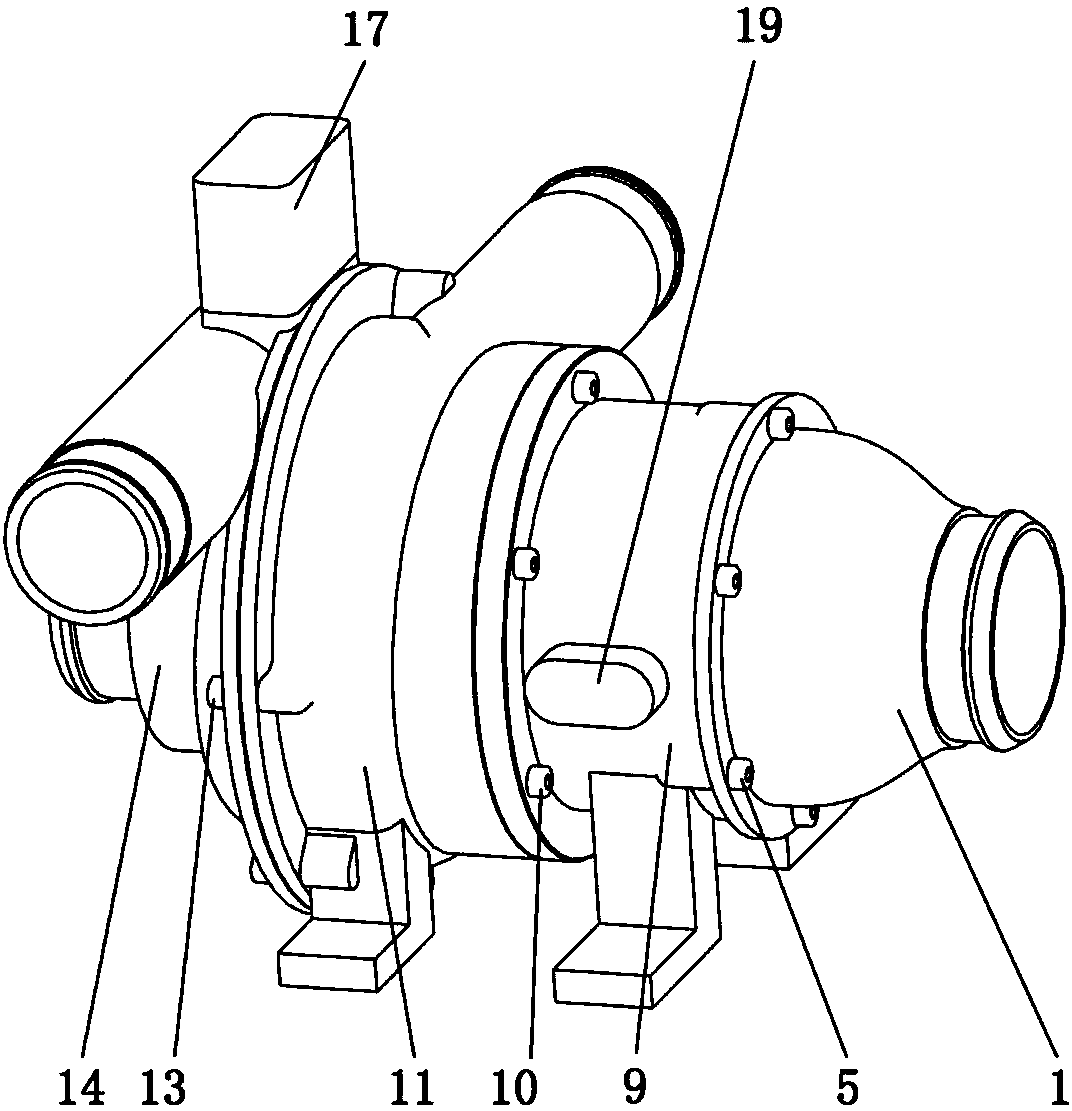

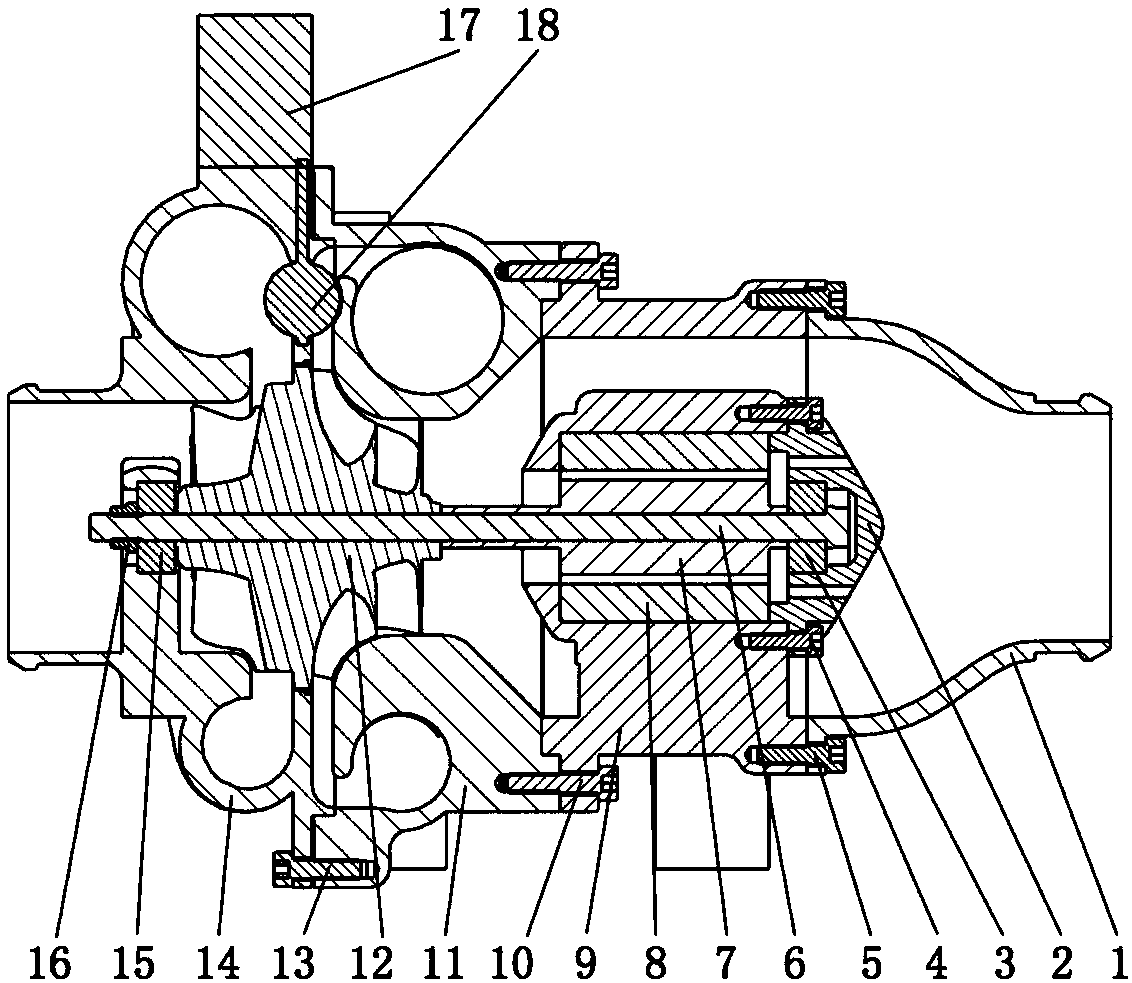

[0026] Such as figure 1 , 2 A centrifugal fuel cell air compressor with energy recovery function is shown, including a motor casing 9 , a rotor assembly, a compressor casing 11 , an expansion casing 14 and an air intake cover 1 . Motor part is made up of motor housing 9, stator 8, motor cover 2, and motor cover 2 is fixed on the motor housing 9 by motor cover bolt 4.

[0027] The intake cover 1 is connected to the motor casing 9 through the intake cover bolts 5, the motor casing 9 is connected to the compressor casing 11 through the motor casing bolts 10, and the expander casing 14 is fixed to the compressor casing through the expander casing bolts 13. on shell 11.

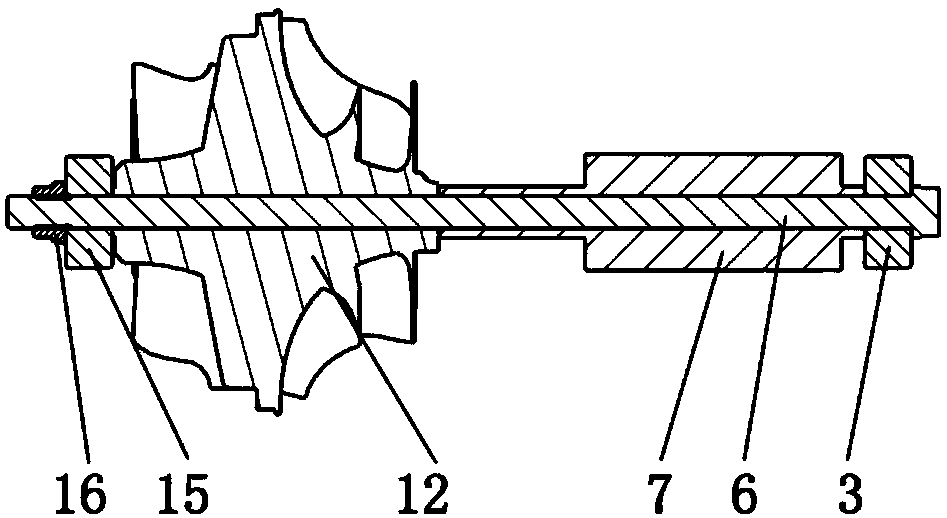

[0028] As shown in Figures 2 and 3, the rotor assembly locks the bearing 3, motor rotor 7, composite impeller 12, and bearing 15 on the rotating shaft 6 through the lock nut 16 to form the rotor assembly. The bearings at both ends of the rotating shaft 6 adopt high-speed rolling bearings, which do not require l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com