Amino acid shampoo composition and preparation method thereof

A composition and shampoo technology, applied in the field of low-cost thickening cleaning compositions, can solve the problems of difficulty in thickening, defoaming, and high cost, and achieve the effects of improving stability, reducing costs, and reducing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1 verifies the synergistic thickening of amino acid surfactants of different weight percentages of betaine surfactants and different weight percentages of sodium α-olefin sulfonate

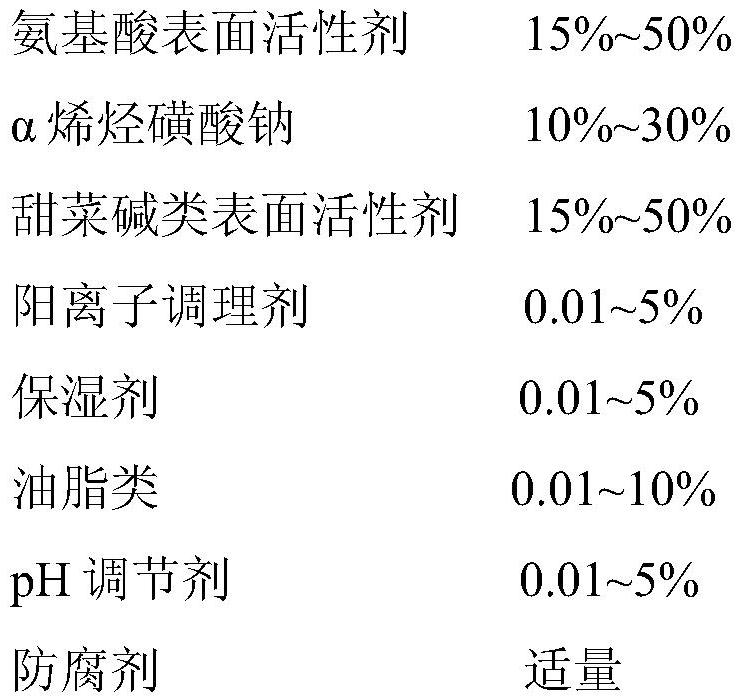

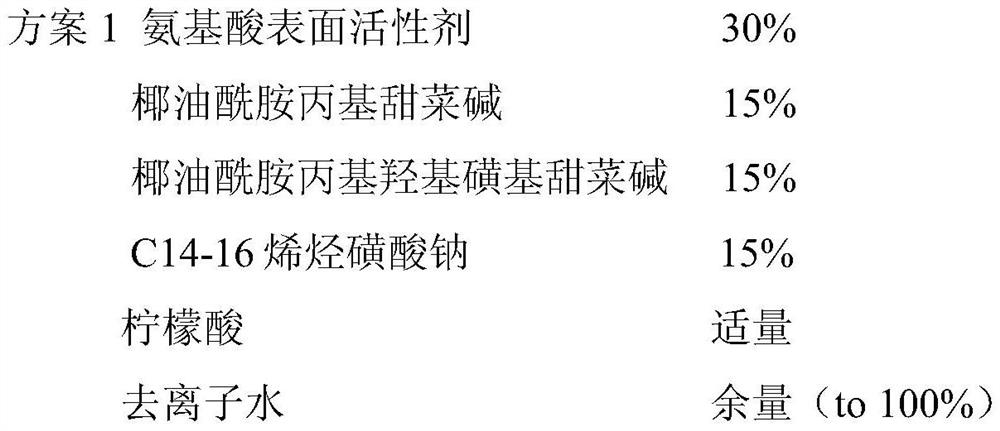

[0056] In order to verify the effects of different weight percentage components and different amino acid types on foaming and thickening effects, the inventors designed the following three schemes. Wherein from scheme 1 to scheme 3, the percentage by weight of betaine surfactant and sodium α olefin sulfonate increases gradually, for each scheme, also designed the different kinds of amino acid surfactant on foaming and thickening effect etc. Influence. See below for specific plans:

[0057]

[0058] Table 1. Physicochemical properties of combinations prepared by different amino acid surfactants in scheme 1

[0059]

[0060]

[0061] Table 2. Physicochemical properties of combinations prepared by different amino acid surfactants in scheme 2

[0062]

[0063] NOTE: Sodiu...

Embodiment 2

[0074] Example 2 Verify the effect of different amounts of amphoteric betaine surface activity and the ratio of sodium α-olefin sulfonate on the thickening effect of amino acid surface activity, and the influence of pH on the viscosity of the system

[0075] Table 4.

[0076]

[0077]

[0078] The thickening ability of composition changes with the ratio of sodium α-olefin sulfonate and amino acid surface activity, and the change of viscosity occurs. Through experiments and experience of the inventor, when sodium α-olefin sulfonate and betaine surface activity The weight ratio of the agent is 0.8-1.2:1.8-2.4, and the formula has a higher viscosity at this time. In addition, it can be seen from the above table that the change of pH will affect the viscosity. Different amino acids have different main surface activities, and their highest viscosity points are different. The highest viscosity of sodium sarcosinate is around 6.0, and a parabola appears with different pH, and ...

Embodiment 4

[0080] Preparation and testing of some amino acid shampoos of embodiment 4

[0081] Prepare some shampoos according to the formulas of Table 5, Table 6, and Table 7.

[0082] Preparation method: S1: Add appropriate amount of water at low temperature, add cationic conditioner, and disperse well;

[0083] S2: Add betaine surfactant, stir for 1 minute, add amino acid surfactant, and then add sodium α-olefin sulfonate;

[0084] S3: Add the rest of the raw materials in the formula, stir until uniform and then discharge.

[0085] Table 5. Sodium Cocamide Taurate Shampoo

[0086]

[0087]

[0088] Table 6. Monosodium glutamate shampoo

[0089]

[0090] Table 7. Sodium Sarcosinate Shampoo

[0091]

[0092] Table 8 Properties of Different Amino Acid Shampoos

[0093] Viscosity mPA·s Foam height mm Effect Shampoos in Table 5 15000 150 soft and smooth Shampoos in Table 6 4500 140 Lightweight, good wet combing effect Shampoos in Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com