Scrap metal shredding and classifying device and treatment method thereof

A sorting device and scrap metal technology, applied in chemical instruments and methods, grain processing, magnetic separation, etc., can solve the problems of locked manual sorting, time-consuming and labor-intensive, easy jamming of metal shredding devices, etc., to avoid rolling blades and Wear, reduce secondary adsorption, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

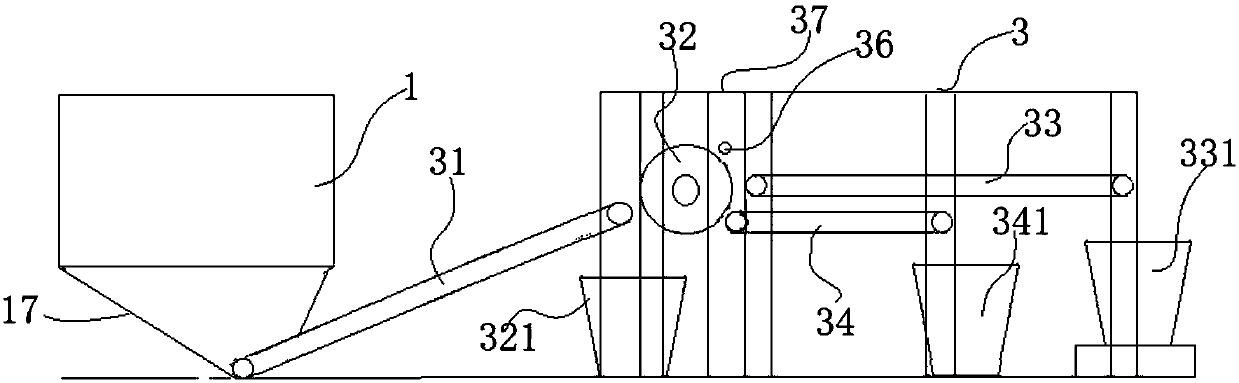

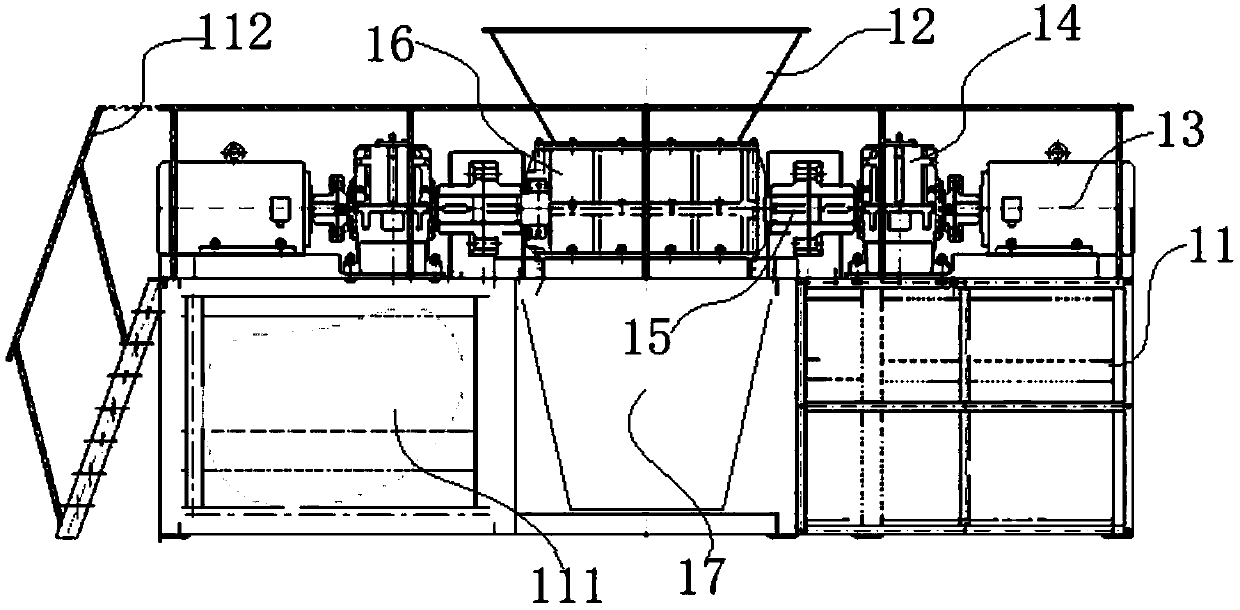

[0043] A scrap metal shredding and sorting device, such as figure 1 , 2 , 3, and 4, it includes a shredding device 1 and a sorting device 3 arranged according to the process and connected by a feeding conveyor belt 31. The shredding device includes a frame-shaped frame 11 and a fixed feed inlet in the middle of the upper end surface of the frame 11 12. The size of the material inlet 12 is 1600*1200mm, the size of the frame 11 is 4500*2200*3850mm, and it also includes a shredding mechanism. The motor 13, reducer 14, coupling 15 and shredding tool 16 connected by transmission, the motor 13 is 7.5KW, adjustable motor; the two shredding knives 16 are interlaced and meshed at the bottom of the feeding port 12, biaxial Driven shredding avoids material jamming and locking when shredding metal materials as much as possible. It is especially effective for waste light and thin metal. The output material is evenly thin strips, which is convenient for the next step of shredding. The bot...

Embodiment 2

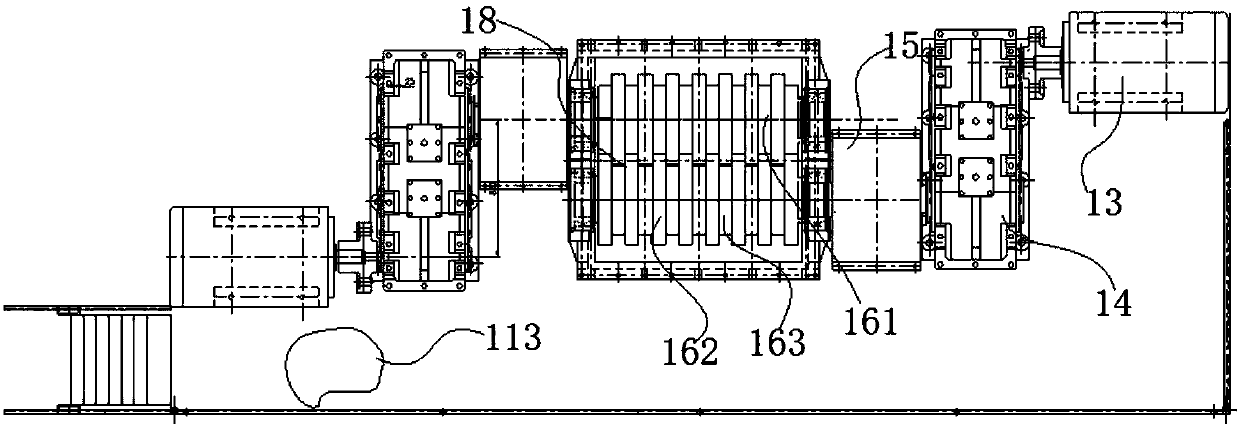

[0046] The scrap metal shredding and sorting device of the present embodiment has the same basic structure as that of Embodiment 1, and the improvement is that the shredding cutter 16 includes an annular cutter 161 and a cutter shaft 163, and the specification of the annular cutter 161 is Φ620*98mm; The shaft 163 is connected to the shaft coupling 15 in a transmission manner. There are several annular cutters 161, which are evenly sleeved and fixed on the axial surface of the cutter shaft 163. A knife groove 162 is formed between every two adjacent annular cutters 161. In two shredding cutters 16, the annular cutter 161 of a shredding cutter 16 and the knife groove 162 of another shredding cutter 16 engage with each other; The worn blade is suitable for cutting metal sheets with a hard texture, and has a long service life without frequent replacement of the blade. There are 2 discharge conveyor belts, which are arranged in parallel up and down. The upper and lower sides are re...

Embodiment 3

[0050] The basic structure of the waste metal shredding and sorting device of this embodiment is the same as that of Embodiment 2, and the improvement is that the annular cutter 161 and the knife groove 162 are seamlessly engaged to avoid light and thin metal materials from being stuck in the gap. Moreover, the width and thickness of the annular cutter 161 and the knife groove 162 are the same, and the two shredding cutters 16 rotate in opposite directions, and the upper part forms a "V"-shaped shredding opening 18 to form a feeding channel, which is easy to operate and avoids blanking dead ends. The delivery speed of the discharge conveyor belt is greater than the feeding speed of the feeding conveyor belt 31. The advantage is that the iron material after the adsorption can be intercepted respectively by the large particle iron material conveyor belt 33 and the small particle iron material conveyor belt 34, and then be transferred as soon as possible to reduce the iron content....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com