Automatic constant temperature separation equipment

A separation equipment, constant temperature technology, applied in the field of automatic constant temperature separation equipment, can solve the problems of high cost, difficult separation, environmental pollution, etc., and achieve the effects of improving separation quality, increasing output and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The automatic constant temperature separation equipment disclosed by the present invention utilizes organic weak acid molecules such as acetic acid and formic acid to penetrate the plastic layer, and then dissolves the metal oxides (such as aluminum oxides) bonded to each layer without dissolving elemental metal. Metal and plastic in the material are completely separated.

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

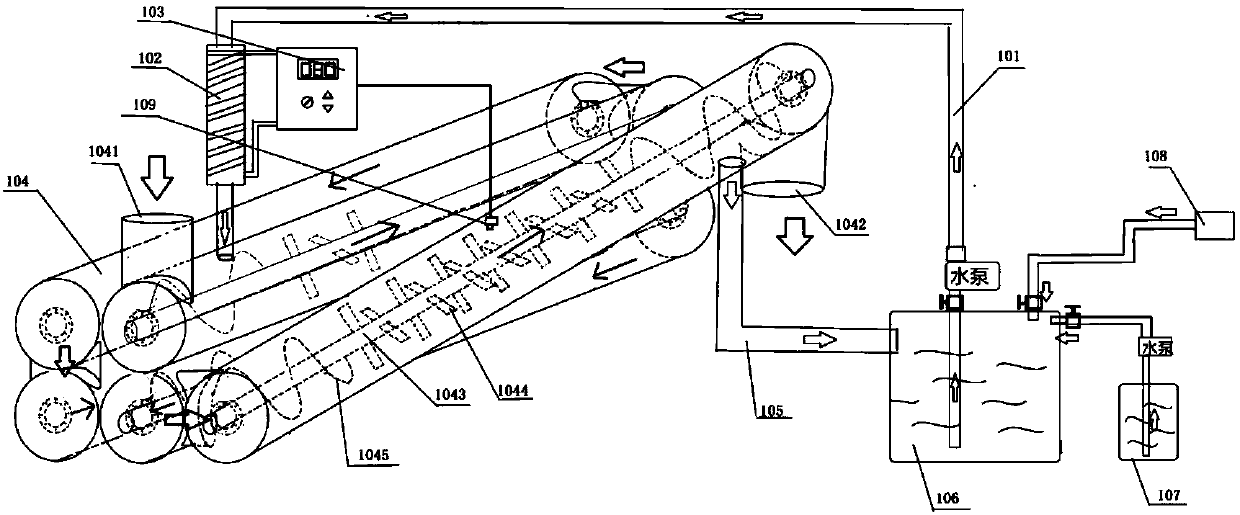

[0025] Such as figure 1 As shown, this embodiment relates to an automatic constant temperature separation device, which can be applied to separate metal and plastic in the composite packaging material of metal and plastic; for example, the automatic constant temperature separation device is applied to the composite Aluminum and plastics in the packaging material; specifically, the equipment includes a liquid inlet pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com