Building brick and manufacturing method thereof

A technology of bricklaying and parts by weight, which is applied in the direction of building structure, building components, buildings, etc., can solve the problems of building safety impact and failure to meet the architectural design requirements of high-rise buildings, and achieve good thermal insulation effect, light weight, The effect of good fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: A kind of bricklaying, is made of the following components in parts by weight: 40 parts of expanded perlite, 25 parts of clay, 12 to 18 parts of quartz sand, 5 parts of cement, 5 parts of talcum powder, and 4 parts of quicklime And 10 parts of water, 2 parts of polystyrene particles and 28 parts of vitrified microbead particles.

Embodiment 2

[0024] Embodiment 2: A kind of bricklaying, is made of the following components by weight: 50 parts of expanded perlite, 30 parts of pottery clay, 12-18 parts of quartz sand, 10 parts of cement, 10 parts of talcum powder, 6 parts of quicklime And 15 parts of water, 3 parts of polystyrene particles and 32 parts of vitrified microbead particles.

Embodiment 3

[0025] Embodiment 3: A kind of bricklaying, is made of the following components by weight: 60 parts of expanded perlite, 35 parts of clay, 12 to 18 parts of quartz sand, 15 parts of cement, 15 parts of talcum powder, and 8 parts of quicklime And 20 parts of water, 4 parts of polystyrene particles and 36 parts of vitrified microbead particles.

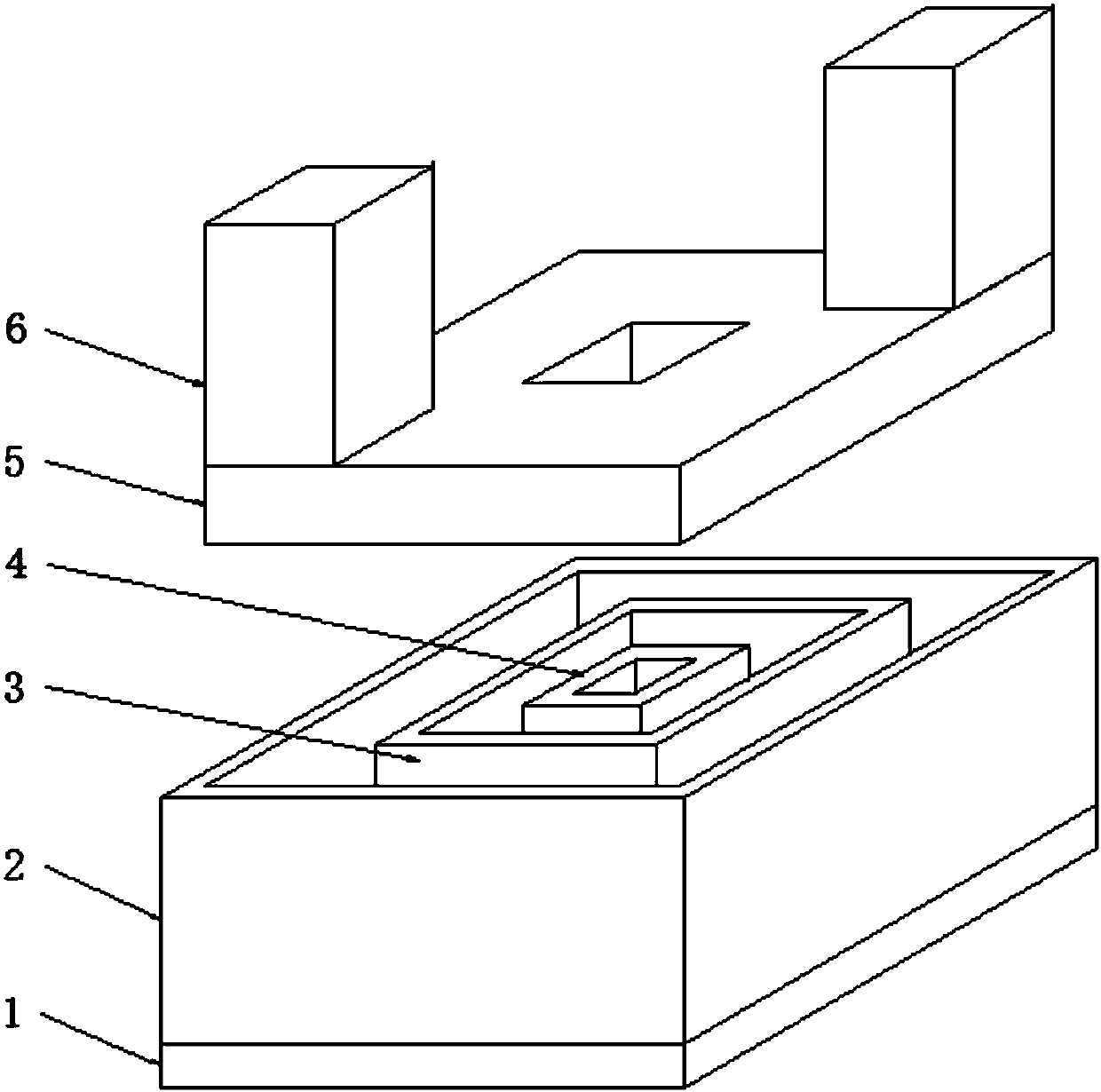

[0026] In the manufacture method of bricklaying in embodiment 1~3, except raw material weight parts are different, other steps are all the same, and specific content comprises the following steps: (1) by weight parts, expand perlite, quartz sand, cement, talc Powder, quicklime and water are mixed and stirred to form a slurry-like mixture A; (2) Vitrified microbead particles, polystyrene particles, clay, cement, talcum powder, quicklime and water are mixed and stirred to form a slurry-like mixture B according to parts by weight (3) Pour the mixture A and the mixture B into the mold respectively, the mold includes a base plate 1 and a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com