High-performance ceramic tile prepared from red mud and preparation method of high-performance ceramic tile

A high-performance, ceramic tile technology, applied in the field of building materials, can solve the problems of affecting the service life of ceramic tiles, poor performance of ceramic tiles, low red mud consumption, etc., achieve low water absorption, meet performance requirements, and broad market prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

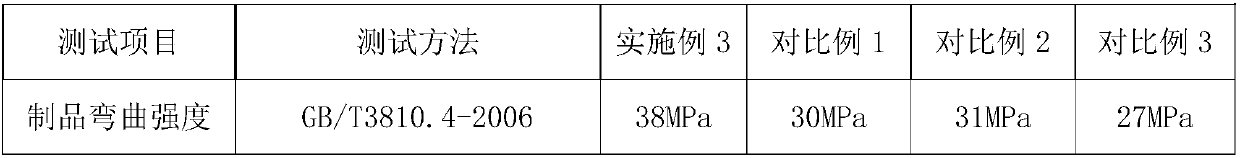

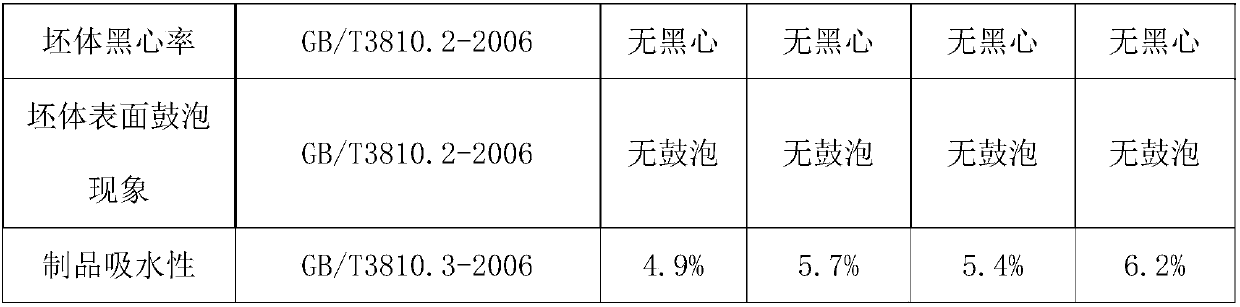

Examples

Embodiment 1

[0028] A high-performance ceramic brick made of red mud, made of the following raw materials in parts by weight: 40 parts of red mud, 28 parts of kaolin, 3 parts of quartz sand, 5 parts of dolomite, 6 parts of talcum powder, zircon 4 parts, andalusite 2 parts, tungsten molybdenum ore 9 parts. Wherein, the red mud is Bayer process red mud; and the andalusite is manganese andalusite.

[0029] In the present embodiment, the preparation method of the high-performance ceramic brick made of red mud, the steps are as follows:

[0030] 1) Weighing zircon, andalusite and tungsten-molybdenum ore, pulverizing them respectively, passing through a 20-mesh sieve, and merging to obtain the first mixture;

[0031] 2) Weigh the red mud, add the first mixture, put it into a ball mill after combining, use water as the grinding liquid, and ball mill and mix for 50 minutes to obtain the second mixture, wherein the amount of water added is 55% of the weight of the red mud ;

[0032] 3) sending t...

Embodiment 2

[0040] A high-performance ceramic brick made of red mud, made of the following raw materials in parts by weight: 41 parts of red mud, 29 parts of kaolin, 6 parts of quartz sand, 8 parts of dolomite, 7 parts of talcum powder, zircon 5 parts, andalusite 4 parts, tungsten molybdenum ore 12 parts. Wherein, the red mud is Bayer process red mud; and the andalusite is manganese andalusite.

[0041] In the present embodiment, the preparation method of the high-performance ceramic brick made of red mud, the steps are as follows:

[0042] 1) Weighing zircon, andalusite and tungsten-molybdenum ore, pulverizing them respectively, passing through a 25-mesh sieve, and merging to obtain the first mixture;

[0043] 2) Weigh the red mud, add the first mixture, put it into a ball mill after combining, use water as the grinding liquid, and ball mill and mix for 53 minutes to obtain the second mixture, wherein the amount of water added is 56% of the weight of the red mud ;

[0044] 3) sending ...

Embodiment 3

[0052] A high-performance ceramic brick made of red mud, made of the following raw materials in parts by weight: 43 parts of red mud, 30 parts of kaolin, 5 parts of quartz sand, 7 parts of dolomite, 8 parts of talcum powder, zircon 6 parts, andalusite 3 parts, tungsten molybdenum ore 11 parts. Wherein, the red mud is Bayer process red mud; and the andalusite is manganese andalusite.

[0053]In the present embodiment, the preparation method of the high-performance ceramic brick made of red mud, the steps are as follows:

[0054] 1) Weighing zircon, andalusite and tungsten-molybdenum ore, pulverizing them respectively, passing through a 30-mesh sieve, and merging to obtain the first mixture;

[0055] 2) Weigh the red mud, add the first mixture, put it into a ball mill after combining, use water as the grinding liquid, and ball mill and mix for 55 minutes to obtain the second mixture, wherein the amount of water added is 58% of the weight of the red mud ;

[0056] 3) sending t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com