Flame-retardant board for leasing space and preparation method thereof

A technology of space and boards, which is applied in the field of flame-retardant boards for space rental and its preparation, can solve the problems of difficult synthesis and high application costs of flame-retardant and smoke suppressants, and achieve reduced production costs, high promotion and application value, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Preparation of flame-retardant panels for space leasing:

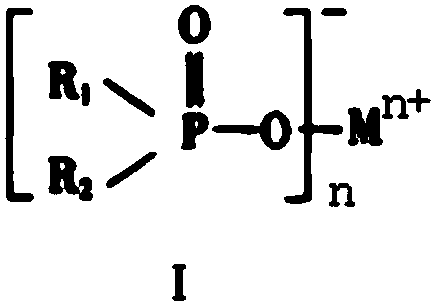

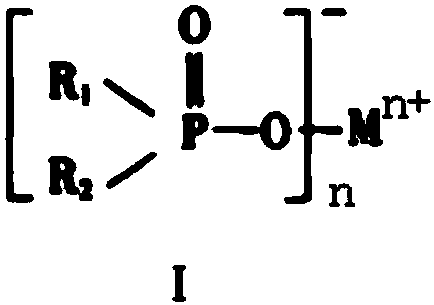

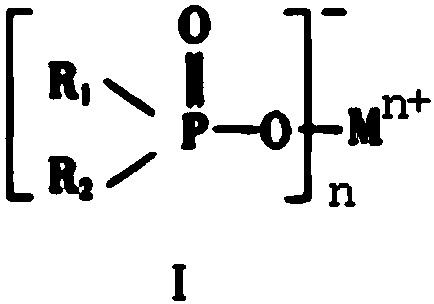

[0049] (1) Preparation of flame retardant and smoke suppressant: in parts by weight, 10 parts of alkylphosphinic acid represented by formula (I), 1 part of tributyltin and 6 parts of tri-n-octylphosphine oxide were mixed at 240°C for 20 minutes, Then keep it warm at 260°C for 1.5h, where, R 1 is methyl; R 2 Be phenyl, M is Al, n is 3, obtains flame retardant and smoke suppressant A1;

[0050] (2) In parts by weight, 75 parts of PVC-SG5 type polyvinyl chloride, 100 parts of nanoscale calcium carbonate, 2 parts of dimethyl tin oxide PVC stabilizer, 0.5 part of stearic acid, ACR K-123 modifier 2 parts and 15 parts of flame retardant and smoke suppressant A1, hot mixed at 120°C for 1.5h, then cold mixed at 60°C for 20min, and then extruded at 160°C.

[0051]

Embodiment 2

[0053] Preparation of flame-retardant panels for space leasing:

[0054] (1) Preparation of flame retardant and smoke suppressant: in parts by weight, 10 parts of alkyl phosphinic acid shown in formula (I), 2 parts of tributyltin and 8 parts of tri-n-octylphosphine oxide were mixed at 245°C for 25 minutes, Then keep it warm at 270°C for 2h, where, R 1 is n-propyl; R 2 It is an isopropyl group substituted by a hydroxyl group at the 1 position, M is Al, and n is 3 to obtain the flame retardant and smoke suppressant A2;

[0055] (2) In parts by weight, 100 parts of PVC-SG5 type polyvinyl chloride, 125 parts of nanoscale calcium carbonate, 4.5 parts of dimethyl tin oxide PVC stabilizer, 0.8 part of stearic acid, ACR K-123 modifier 2.8 parts and 20 parts of flame retardant and smoke suppressant A2, hot mixed at 130°C for 1.2h, then cold mixed at 70°C for 30min, and then extruded at 180°C.

Embodiment 3

[0057] Preparation of flame-retardant panels for space leasing:

[0058] (1) Preparation of flame retardant and smoke suppressant: in parts by weight, 10 parts of alkylphosphinic acid shown in formula (I), 3 parts of tributyltin and 10 parts of tri-n-octylphosphine oxide were mixed at 250°C for 30 minutes, Then it was incubated at 280°C for 2.5h, wherein, R 1 For the n-hexyl substituted by chlorine at the 6-position; R 2 It is a methyl group substituted by an amino group, M is Al, and n is 3, and the flame retardant and smoke suppressant A3 is obtained.

[0059] (2) In parts by weight, 120 parts of PVC-SG5 type polyvinyl chloride, 150 parts of nanoscale calcium carbonate, 7 parts of dimethyl tin oxide PVC stabilizer, 1.2 parts of stearic acid, ACR K-123 modifier 3.5 parts and 25 parts of flame retardant and smoke suppressant A3, hot mixed at 140°C for 2 hours, then cold mixed at 80°C for 40 minutes, and then extruded at 210°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com