Composite crease-resistant and pilling-resistant finishing agent and preparation method thereof

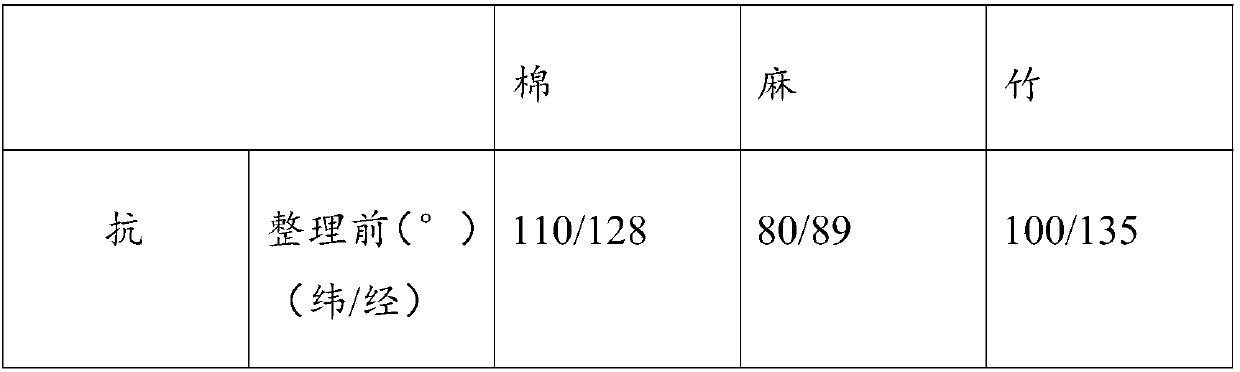

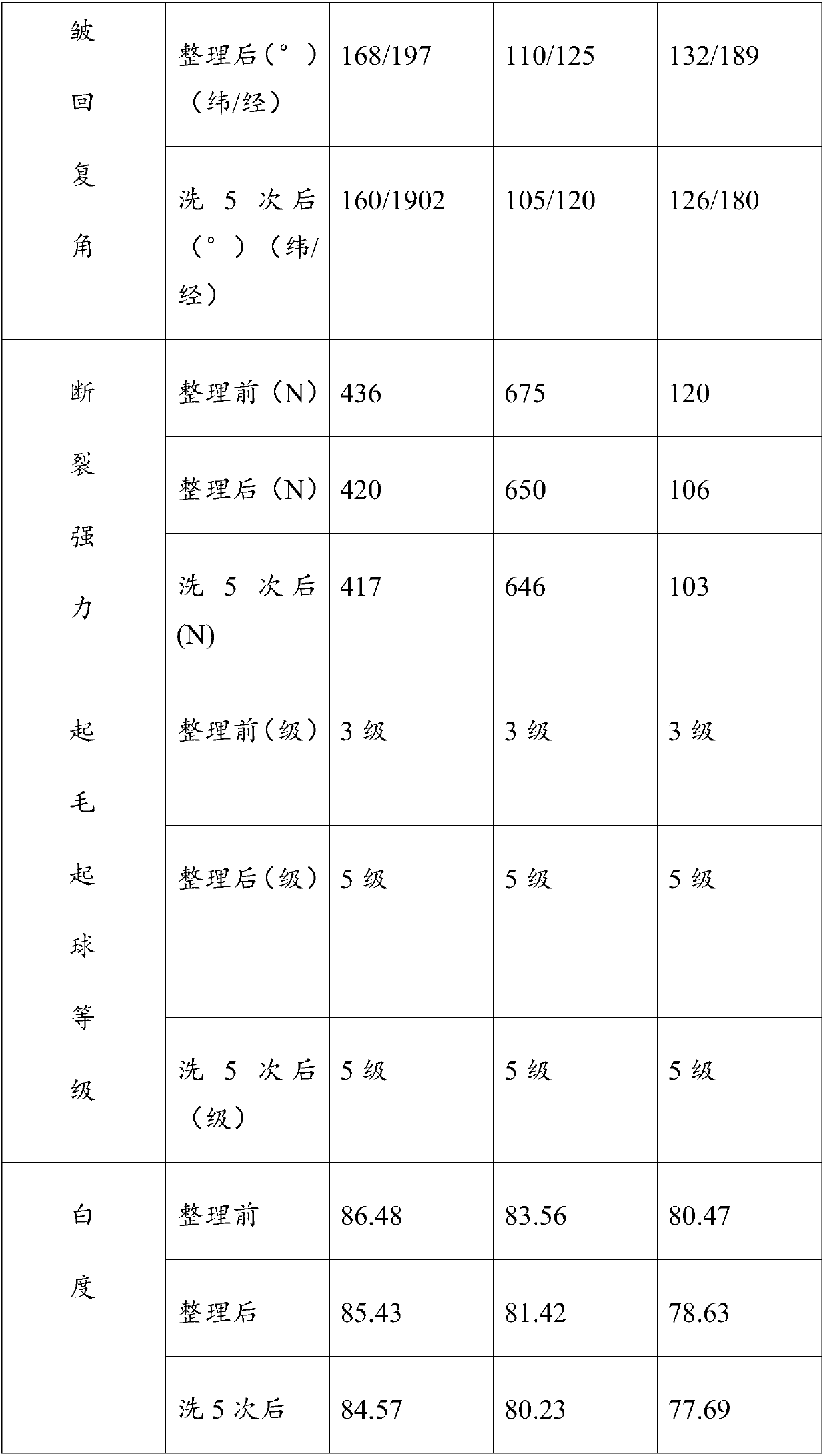

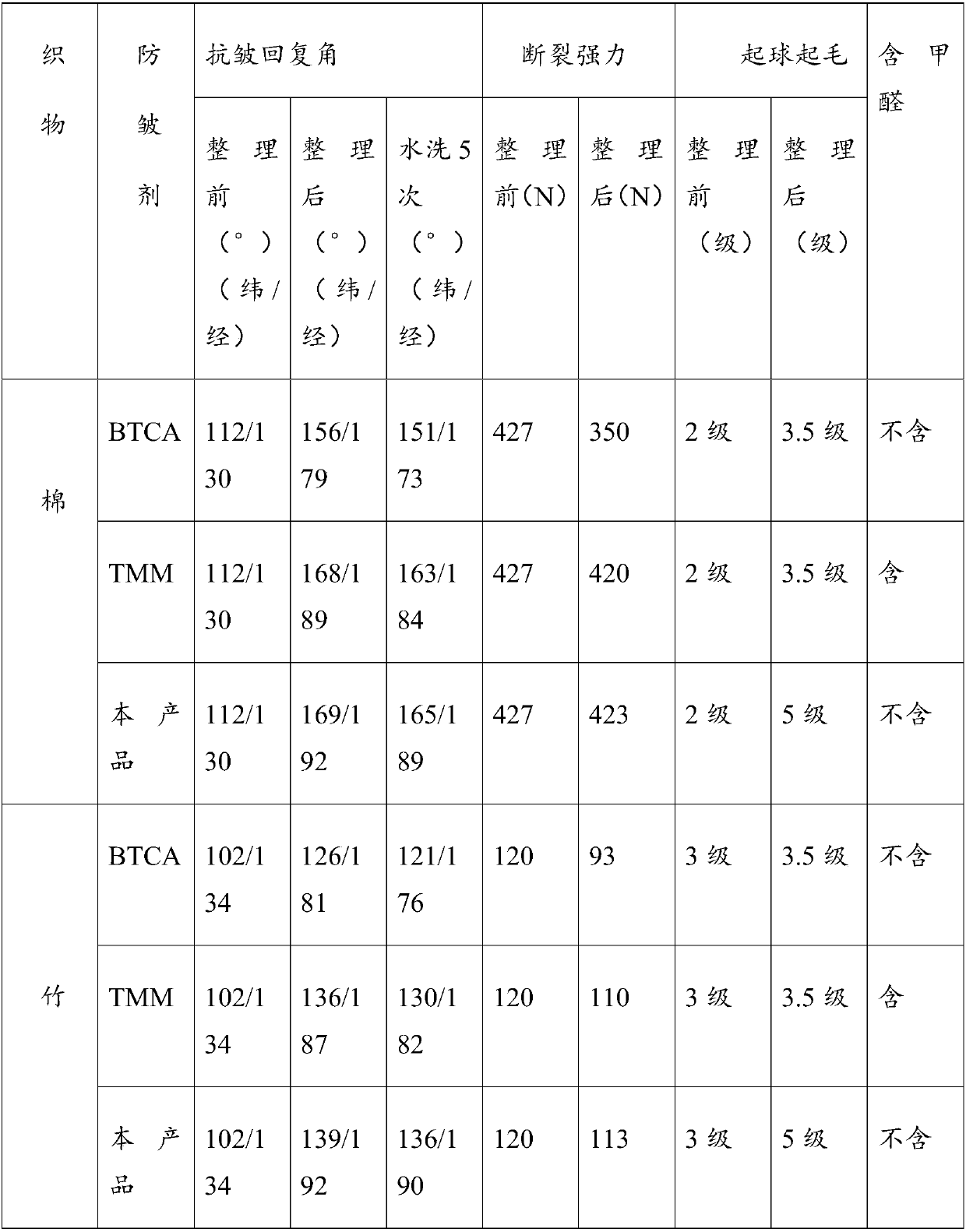

A treatment agent and anti-pilling technology, which is applied in fiber treatment, wear-resistant fibers, textiles and papermaking, etc. It can solve problems such as easy pilling, strong damage to fabrics, stiff and rough hand feeling, etc., to improve wrinkle resistance and reduce slippage. Move, improve the effect of pilling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A composite anti-wrinkle and anti-fluff treatment agent, comprising the following components in mass percentage, ethyl hydrogen-containing silicone oil 10%, sorbitan fatty acid ester S-20 2%, secondary alcohol polyoxyethylene ether S-50 2%, Maleic anhydride 10%, water-soluble azo initiator V-50 0.2%, viscosity 1000cPs polydimethylsiloxane 12%, polyglycidyl ether 10%, polyoxyethylene sorbitan fatty acid ester T-20 4%, diethylene glycol monobutyl ether 1%, polyvinyl alcohol 2%, and the rest is deionized water.

[0028] Above-mentioned polyvinyl alcohol selects the polyvinyl alcohol of medium viscosity that molecular weight is 110000 for use.

[0029] The preparation method of the composite anti-wrinkle and anti-fluff treatment agent comprises the following steps: 1) preparing each component according to the above-mentioned mass percentage for future use.

[0030] Preparation of component A: Add sorbitan fatty acid ester S-20, secondary alcohol polyoxyethylene ether S-50 ...

Embodiment 2

[0042] A composite anti-wrinkle and anti-fluff treatment agent, comprising the following components in mass percentage, ethyl hydrogen-containing silicone oil 12%, sorbitan fatty acid ester S-40 3%, secondary alcohol polyoxyethylene ether S-70 2.5%, Cyclopentetate anhydride 12%, water-soluble azo initiator VA-044 0.3%, viscosity 2000cPs polydimethylsiloxane 10%, polyglycidyl ether 8%, polyoxyethylene sorbitan fatty acid ester T -40 3%, diethylene glycol monobutyl ether 0.8%, polyvinyl alcohol 1.5%, and the rest is deionized water.

[0043] Above-mentioned polyvinyl alcohol selects the polyvinyl alcohol of medium viscosity that molecular weight is 120000 for use.

[0044] The preparation method of the composite anti-wrinkle and anti-fluff treatment agent comprises the following steps: 1) preparing each component according to the above-mentioned mass percentage for future use.

[0045] Preparation of component A: Add sorbitan fatty acid ester S-40, secondary alcohol polyoxyethy...

Embodiment 3

[0055] A compound anti-wrinkle and anti-pilling treatment agent, comprising the following components in mass percentage, 15% of hydroxyl hydrogen-containing silicone oil, 4% of sorbitan fatty acid ester S-60, 3% of secondary alcohol polyoxyethylene ether S-70, cyclo Glutaric anhydride 15%, water-soluble azo initiator VA-044 0.3%, viscosity 4000cPs polydimethylsiloxane 10%, polyglycidyl ether 7%, polyoxyethylene sorbitan fatty acid ester T- 60 3%, diethylene glycol monobutyl ether 0.7%, polyvinyl alcohol 1%, and the rest is deionized water.

[0056] Above-mentioned polyvinyl alcohol selects the polyvinyl alcohol of medium viscosity that molecular weight is 130000 for use.

[0057] The preparation method of the composite anti-wrinkle and anti-fluff treatment agent comprises the following steps: 1) preparing each component according to the above-mentioned mass percentage for future use.

[0058] Preparation of component A: Add sorbitan fatty acid ester S-60, secondary alcohol po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com