Digital holographic microscopy device based on local hollow beam illumination and working method thereof

A local hollow beam, digital holographic microscopy technology, applied in the research field, can solve the problems of poor controllability, weak imaging contrast, loss of light energy, etc., to achieve high contrast, improve imaging contrast, and improve imaging resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

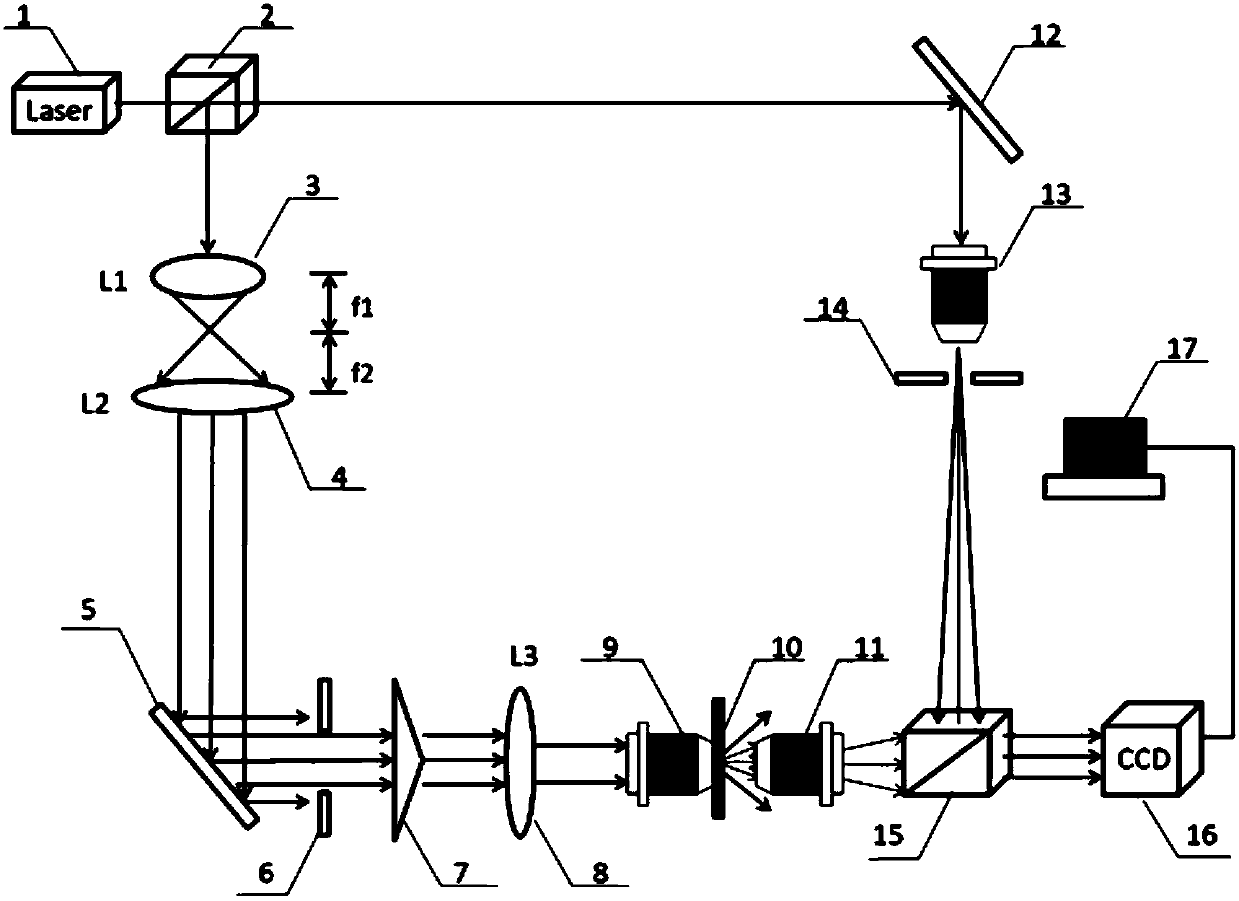

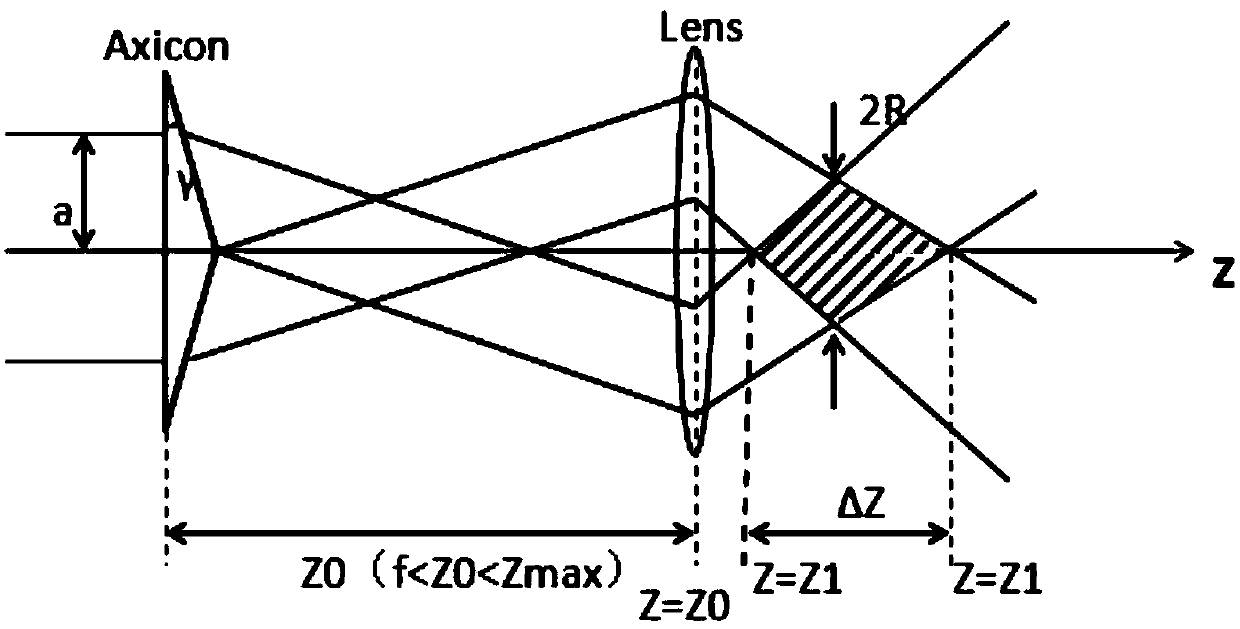

[0040] Embodiment 1: as Figure 1-8 As shown, a dark-field digital holographic microscope device based on local hollow beam illumination, including a laser 1, an optical beam splitter I 2, an optical beam splitter II 15, a microscope objective I 11, a microscope objective II 13, Pinhole filter 14, optical mirror I 5, optical mirror II 12, first lens L1 3, second lens L2 4, third lens L3 8, diaphragm 6, cone mirror 7, dark field condenser 9, experiment Sample 10, optocoupler device 16, computer 17; wherein the laser light emitted by laser 1 is irradiated on optical beam splitter I 2; optical beam splitter I 2, optical beam splitter II 15, optical reflector I 5 and optical reflector II 12 forms a Mach-Zehnder optical path system on the optical platform, wherein the optical beam splitter I 2 is on the same horizontal line as the optical mirror II12, and the optical beam splitter I 2 is on the same vertical line as the optical mirror I 5 , the optical mirror II12 and the optical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com