A kind of preparation method of lithium-rich manganese cathode material with high specific capacity

A positive electrode material and high specific capacity technology, applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of large-scale application limitations, complex preparation process, mixed cations, etc., and achieve a narrow range of powder particle size distribution, The effect of simple preparation process and easy manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

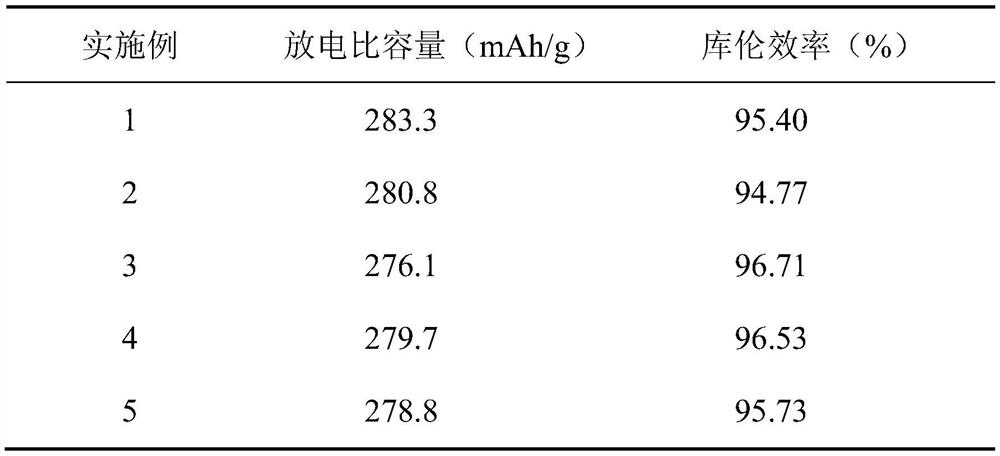

Examples

Embodiment 1

[0059] Weigh LiNO respectively according to the stoichiometric molar ratio of 1.2:0.2:0.6 3 , Ni(CH 3 COO) 2 4H 2 O and Mn(CH 3 COO) 2 4H 2 O, where the lithium source LiNO 3 Weighing adopts 3wt% excess; the weighed LiNO 3 Dissolve in 150ml ethanol, stir magnetically at room temperature, and add Ni(CH 3 COO) 2 4H 2 O, add Mn(CH 3 COO) 2 4H 2 O, then magnetically stirred for 1h to form a green transparent solution, wherein the magnetic stirring speed was 500r / min; take polyethylene glycol PEG400, and add it dropwise to the green transparent solution, and the rate of dropping was controlled as 1 drop per second , to ensure that the molar ratio of polyethylene glycol to Li, Ni and Mn metal ions is 1:1.5, magnetically stir for 1h, and the stirring speed is 500r / min to form a green emulsion; put the green emulsion in a water bath at 75°C for 4h, At the same time, stir magnetically until a green viscous liquid is formed, the magnetic stirring rate is 350r / min, and the v...

Embodiment 2

[0063] Weigh LiNO respectively according to the stoichiometric molar ratio of 1.2:0.2:0.6 3 , Ni(CH 3 COO) 2 4H 2 O and Mn(CH 3 COO) 2 4H 2 O, where the lithium source LiNO 3 Weighing adopts 4.5wt% excess; the weighed LiNO 3 Dissolve in 180ml ethanol, stir magnetically at room temperature, and add Ni(CH 3 COO) 2 4H 2 O, add Mn(CH 3 COO) 2 4H 2 O, then magnetically stirred for 1h to form a green transparent solution, wherein the magnetic stirring speed was 550r / min; take polyethylene glycol PEG400 and add it dropwise to the green transparent solution, and the rate of dropping was controlled at 1 drop per second , to ensure that the molar ratio of polyethylene glycol to Li, Ni and Mn metal ions is 1:1.5, magnetically stir for 1.5h, and the stirring speed is 550r / min to form a green emulsion; put the green emulsion in a water bath at 80°C for 4h , and at the same time magnetically stir until a green viscous liquid is formed, the magnetic stirring rate is 400r / min, an...

Embodiment 3

[0067] Weigh LiNO respectively according to the stoichiometric molar ratio of 1.2:0.2:0.6 3 , Ni(CH 3 COO) 2 4H 2 O and Mn(CH 3 COO) 2 4H 2 O, where the lithium source LiNO 3 Weighing adopts 6wt% excess; the weighed LiNO 3 Dissolve in 200ml ethanol, stir magnetically at room temperature, dissolve evenly and then add Ni(CH 3 COO) 2 4H 2 O, add Mn(CH 3 COO) 2 4H 2 0, then magnetically stirred for 1.5h to form a green transparent solution, wherein the magnetic stirring speed was 550r / min; get polyethylene glycol PEG400 and add it dropwise to the green transparent solution, and the rate of dropping was controlled as 2 per second Make sure that the molar ratio of polyethylene glycol to Li, Ni and Mn metal ions is 1:2, magnetically stir for 1.5h, and the stirring speed is 550r / min to form a green emulsion; put the green emulsion in a water bath at 78°C 4.5h, at the same time, stir magnetically until a green viscous liquid is formed, the magnetic stirring rate is 380r / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com