Piercing device and method for beverage capsules

A processing device and capsule technology, which is applied in metal processing and other directions, can solve problems such as deformation, increased production cost, and impact on punching process production efficiency and yield, so as to reduce production cost, improve production efficiency, and smooth the punching area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

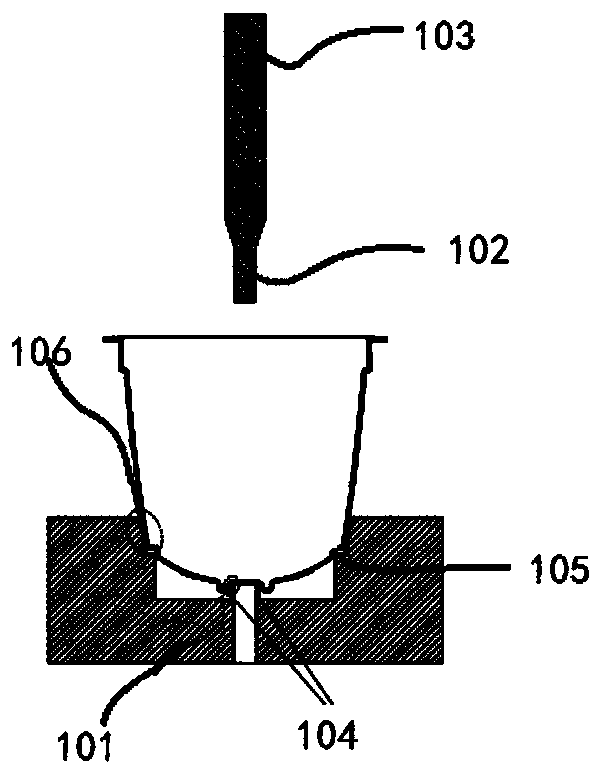

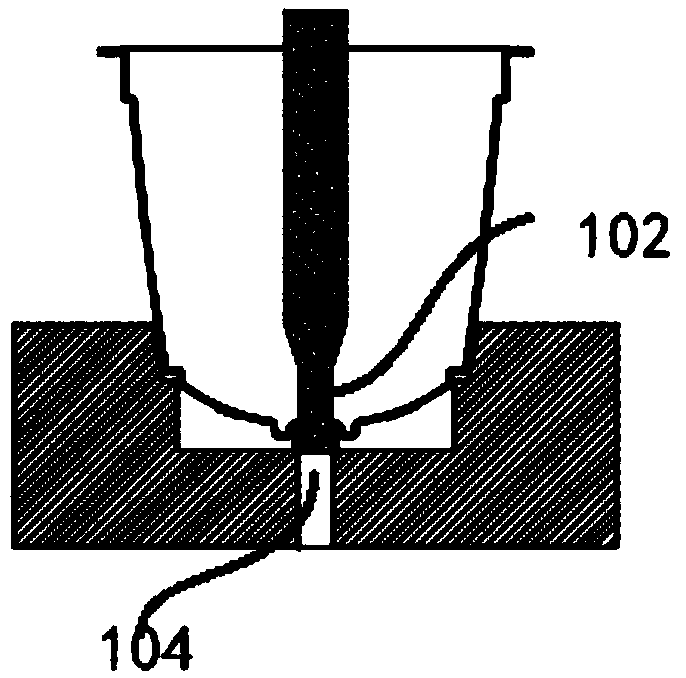

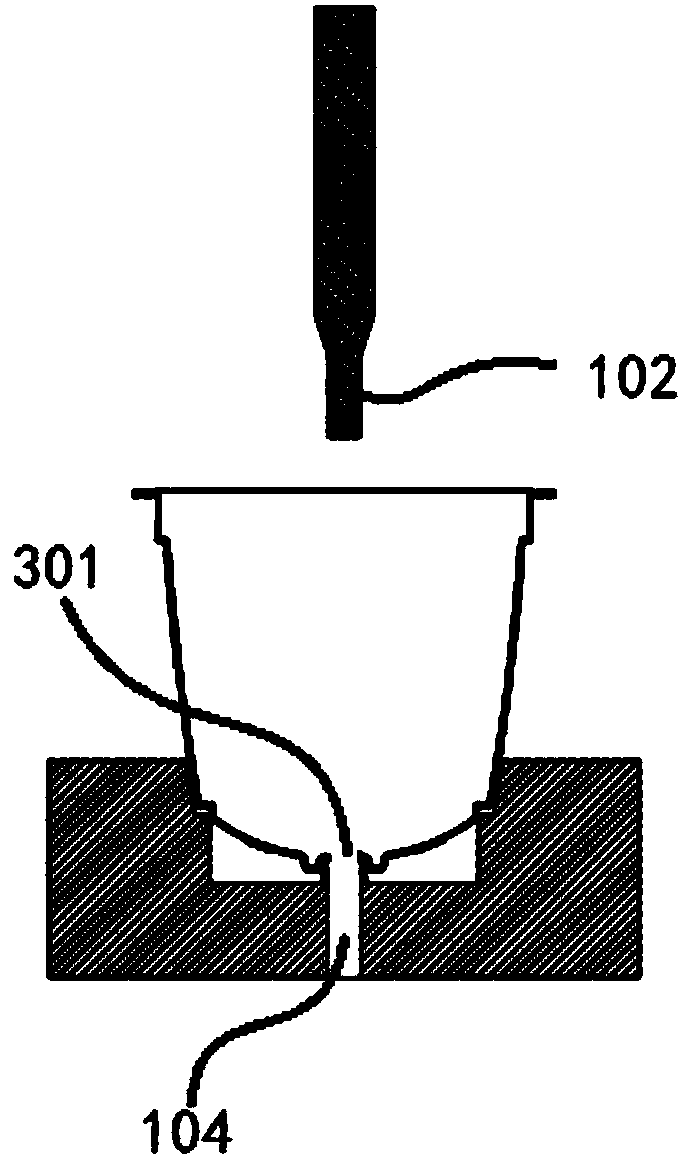

[0024] figure 1 Shown is a state diagram of the beverage capsule punching processing device according to the present invention before punching, figure 1 Only the punch and the bottom die related to the important improvement points of the present invention are shown in the figure. Although other structures such as drive motors and power supplies are not shown, drive motors, stepping motors, servo motors, etc. are commonly used in industrial production lines. device, and the punching processing device of the present invention does not involve changes in driving and transport devices, and thus only shows the setting relationship of the punch and the bottom die involved in achieving the improved punching effect. Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com