Outer-window waterproof structure in masonry project and construction method of outer-window waterproof structure

A waterproof structure and exterior window technology, which is applied to building components, building structures, buildings, etc., can solve problems such as many quality problems, inconsistent construction practices, and uneven waterproofing of exterior windows, so as to prevent water retention and reduce Leakage risk, good waterproof and anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The main principle of this embodiment is: the dry wall is directly combined with the aluminum alloy imitation steel window, the construction nodes are mainly distributed in the window opening, and whether the window opening leaks mainly depends on whether the quality control during installation and splicing is in place. Usually after the external windows are installed, the surrounding walls will be painted. Window construction can be judged from historical data. In the construction of the waterproof joints of the exterior windows of historically protected buildings, the waterproof requirements must be met while ensuring the construction progress. Therefore, the sub-frame technology is chosen to be used on the exterior windows, and the sealant is used to fill and seal from the inside to the outside.

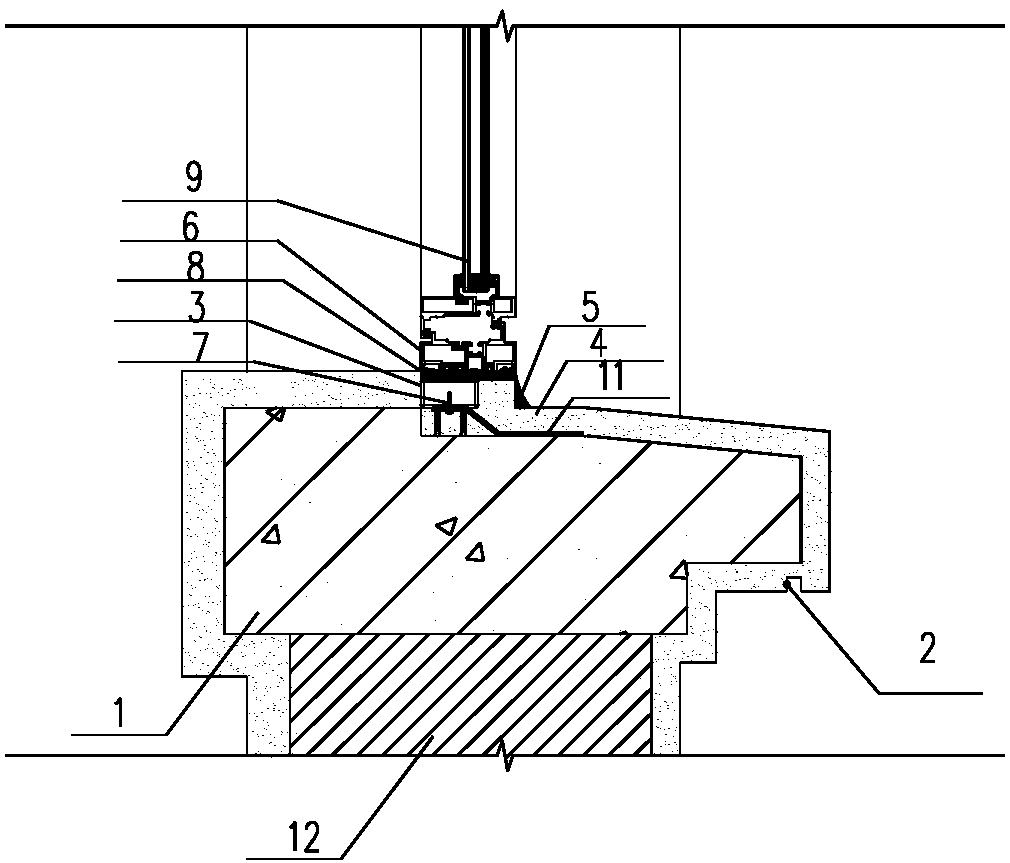

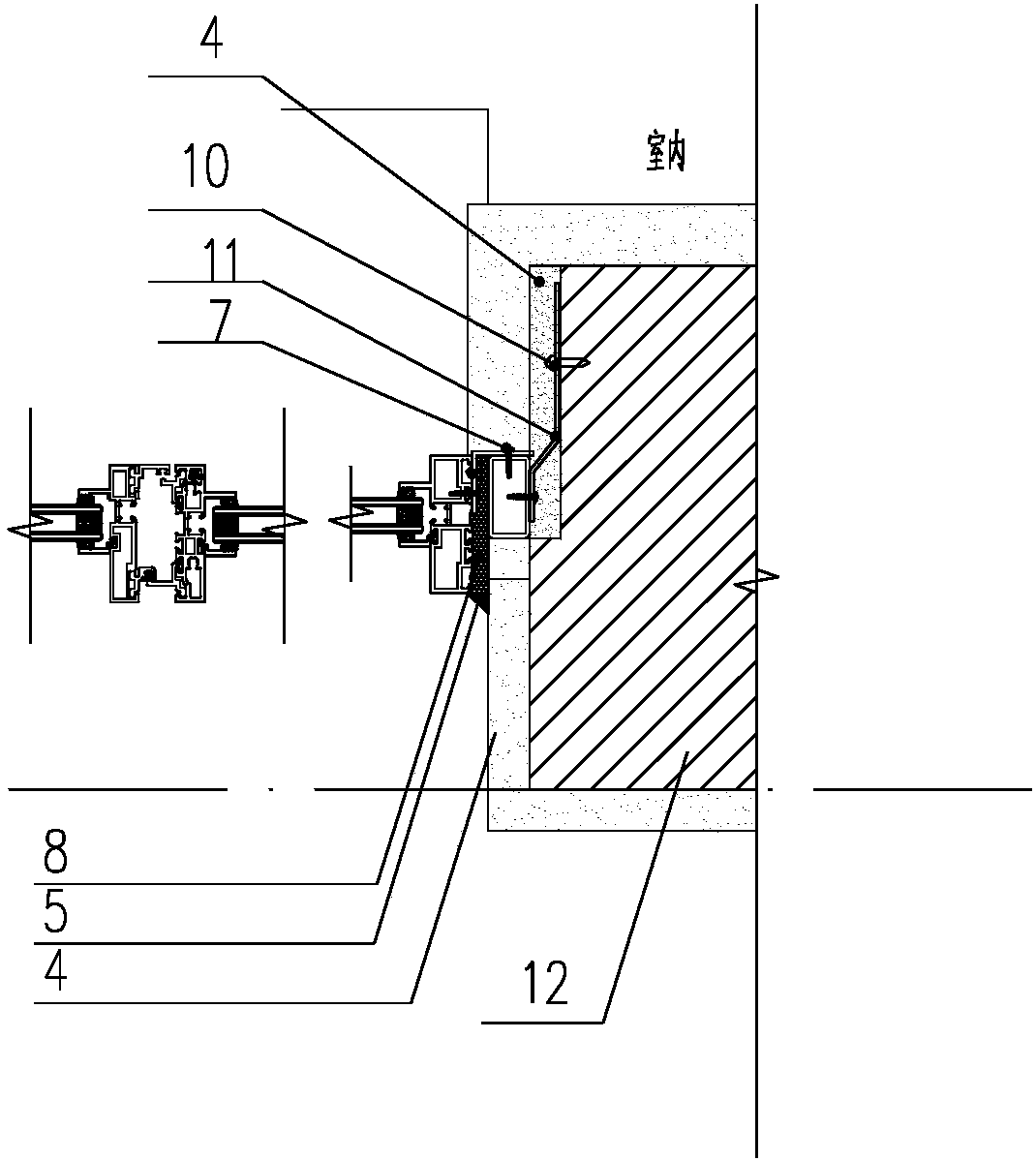

[0032] like figure 1 and figure 2 As shown, a waterproof structure for exterior windows in a masonry project includes a prefabricated reinforced concrete window sill 1, ...

Embodiment 2

[0037] Please continue to refer figure 1 and figure 2 , the present embodiment provides the construction method of the exterior window waterproof structure in the masonry project of the present invention, and this construction method comprises the following steps:

[0038] Step 1: Copy and lay out the lines: In order to ensure that the installation position of the doors and windows is accurate and the appearance is neat, the lines should be copied and laid out when installing the doors and windows. Usually, the horizontal line is drawn first, and the ink line is used to bounce it on the brick wall. The multi-storey building is leveled with the opening on the top floor, and the vertical line is used to pop the center line of the window. A single door and window can be hung straight with a wire hammer on site.

[0039] Step 2 Prefabricated reinforced concrete window sill: Carry out prefabricated reinforced concrete window sill construction, and set a drainage slope on the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com