A Variable Valve Phase Mechanism Based on Sliding Cylinder Liner

A gas timing and sliding cylinder technology, applied in the direction of sliding valves, engine components, combustion engines, etc., can solve the problems that the two-stroke engine with opposed pistons cannot be used, and cannot meet the requirements for ventilation of the two-stroke engine with pistons, and achieves improvement. Ventilation effect, improvement of engine performance, effect of facilitating combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

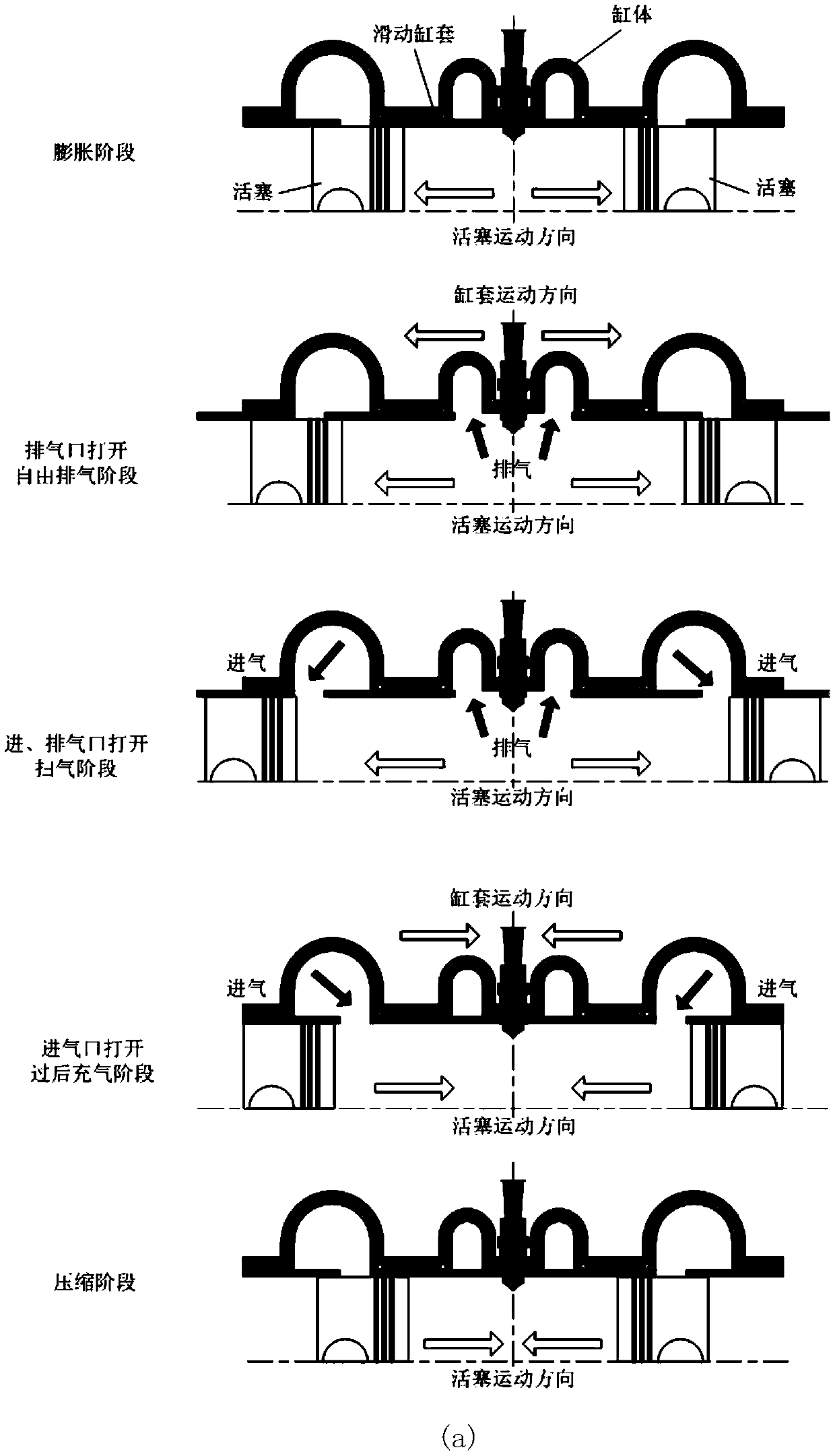

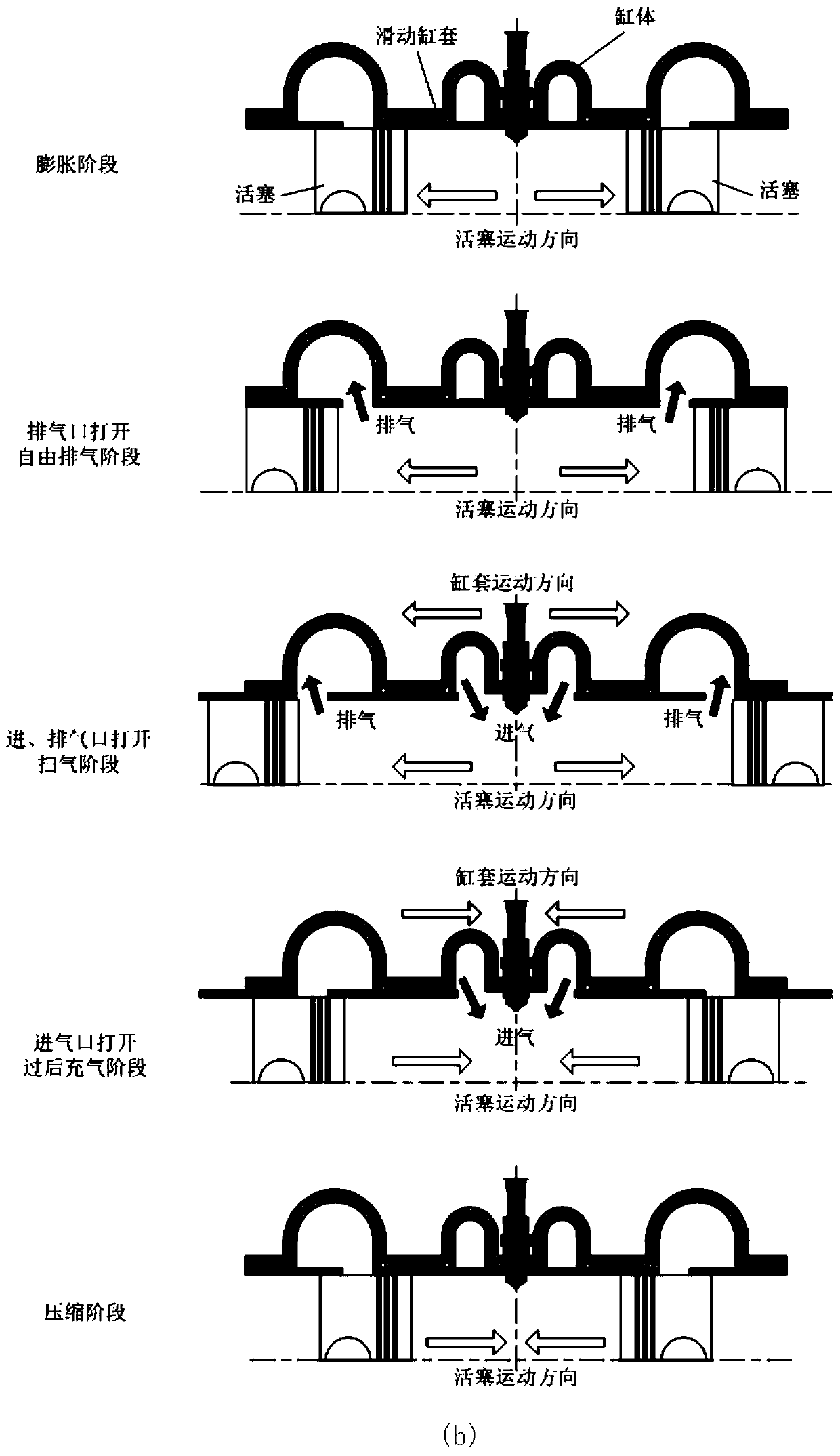

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

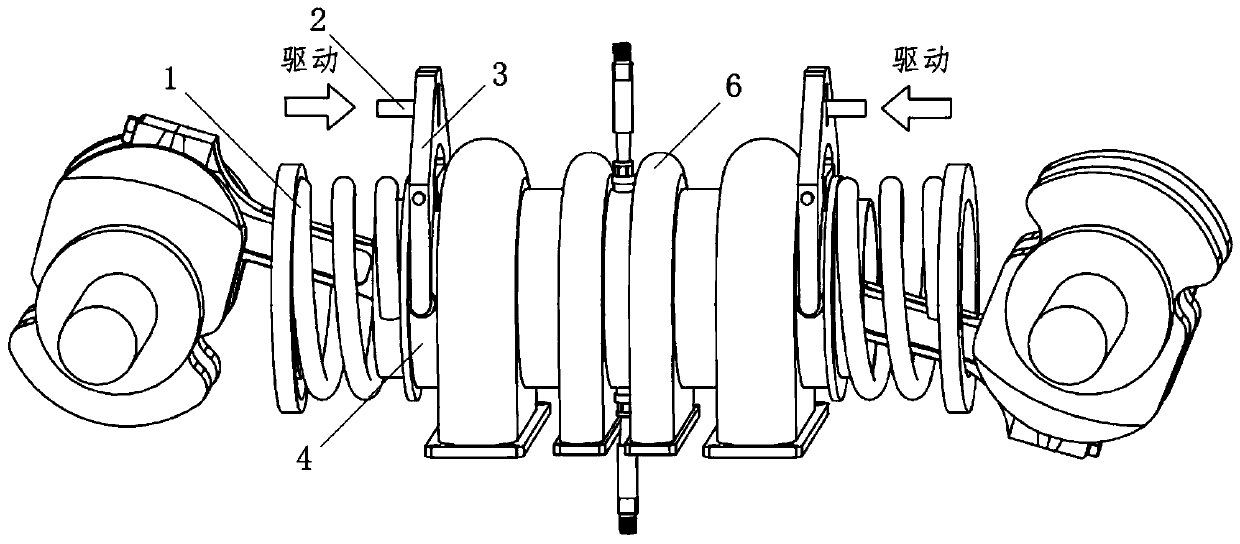

[0026] as attached figure 1 , 3 As shown in and 4, the present invention provides a variable valve timing mechanism based on sliding cylinder liners, which includes sliding cylinder liners 4, 5 on both sides, two electro-hydraulic drive devices 2, 8, rockers 3 on both sides , 7, and locking spring 1,9.

[0027] Air holes distributed along the circumferential direction are processed on the surfaces of the sliding cylinder sleeves 4 and 5;

[0028] Sliding cylinder liners 4,5 are sleeved on the inner side of fixed cylinder liner 6, pistons are sleeved on the inner side of sliding cylinder liners 4,5, and sliding cylinder liners 4,5 are compressed and positioned by locking springs 1,9. Rocking bar 3,7 middle part is fixed with the boss on the fixed cylinder liner 6, and one side of rocking bar 3,7 is connected with driving device 2,8, and one side is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com