Two-degree-of-freedom guide rail for ellipsoidal glass bulb detection

A degree of freedom and ellipsoidal technology, which is applied in measuring devices, optical testing of flaws/defects, and material analysis through optical means, can solve the problem of difficult to guarantee machining accuracy and difficult to process large-sized ellipsoidal guide rails and ellipsoidal guide rails. Difficulty and other problems, to achieve the effect of uniform light source and uniform light emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

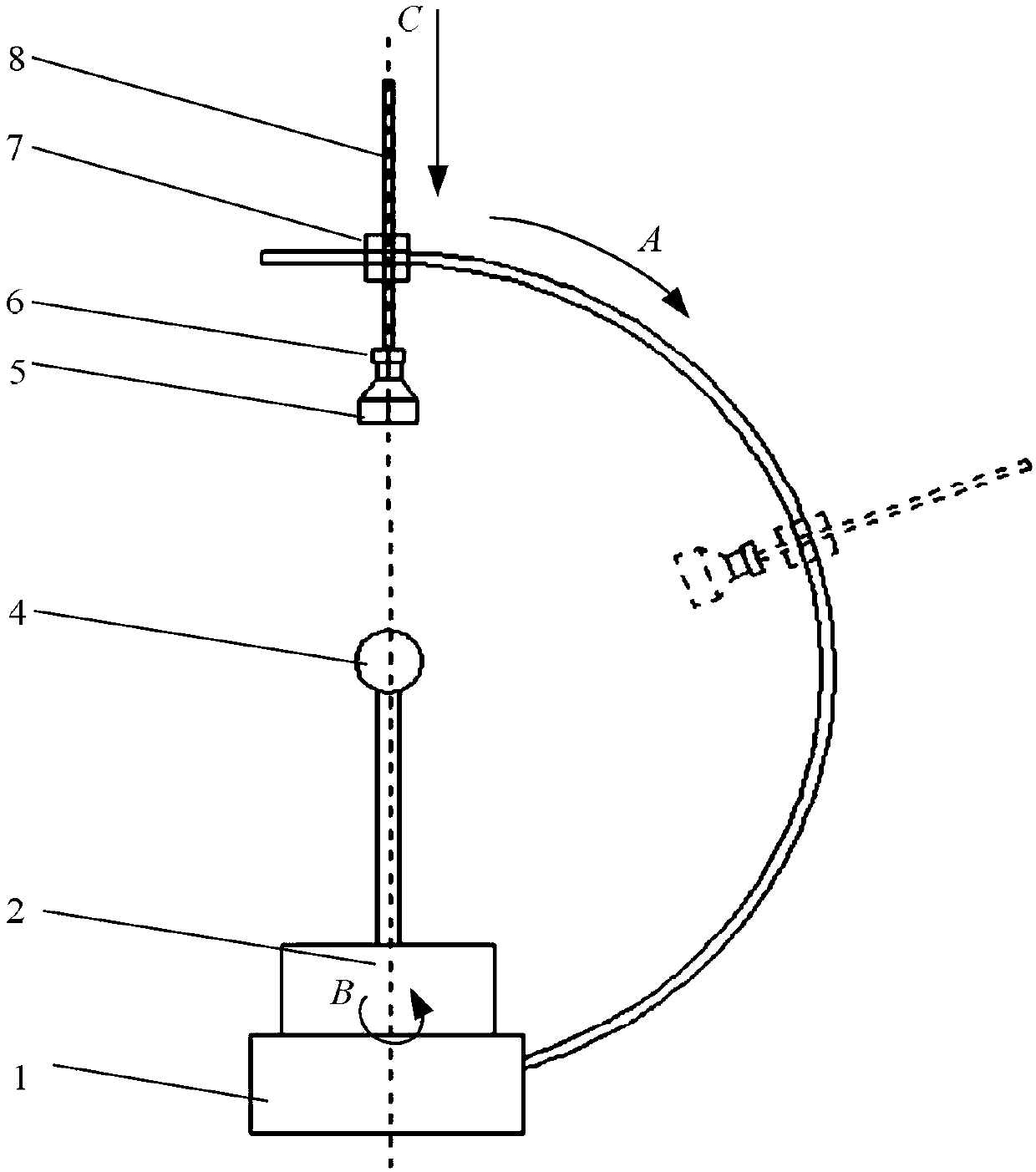

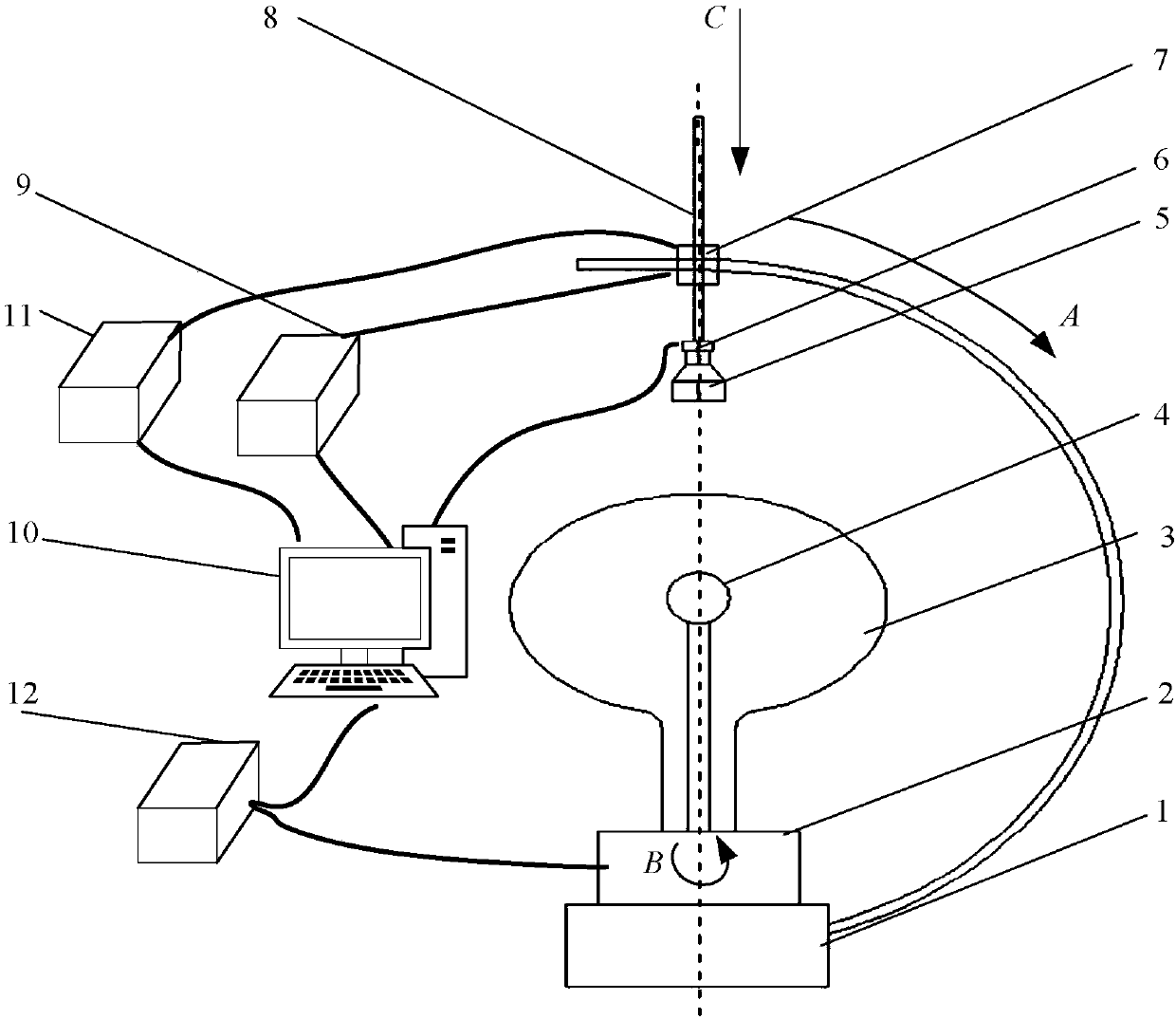

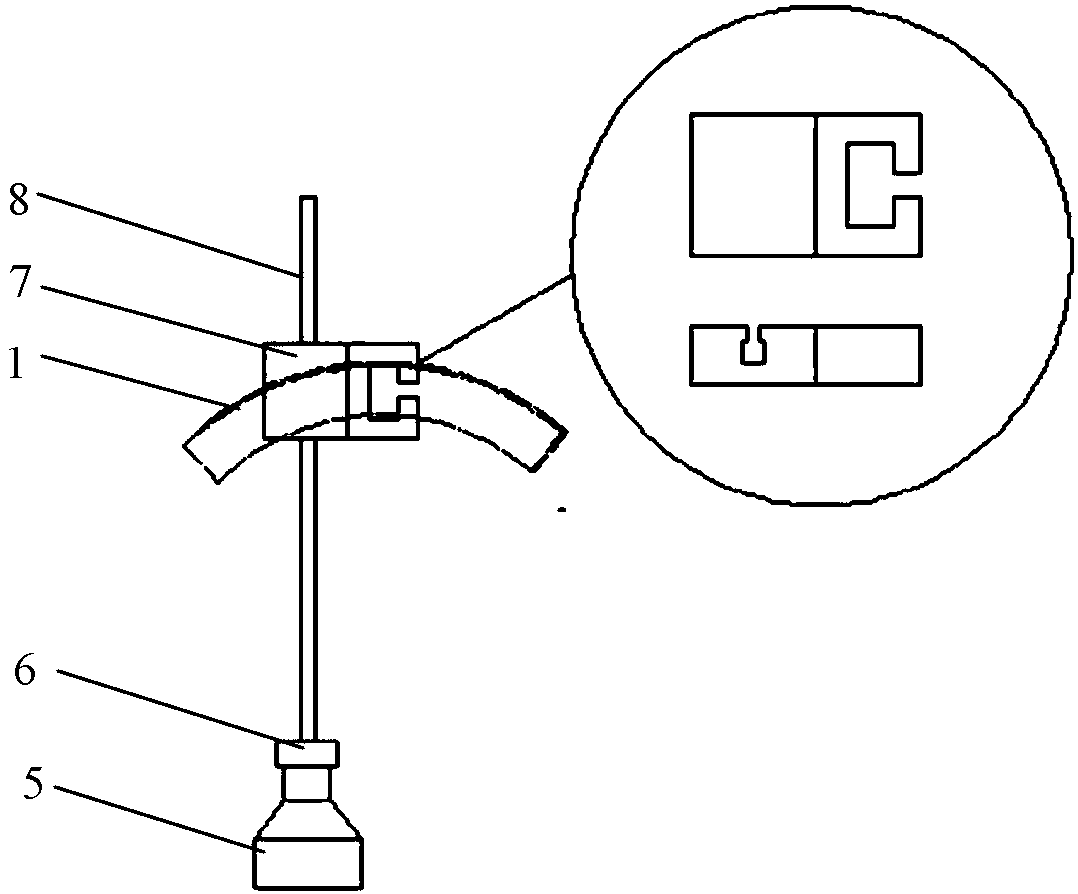

[0020] Specific implementation mode one: as Figure 1~4 As shown, the dual-degree-of-freedom guide rail used for the detection of an ellipsoidal glass bulb in this embodiment includes a guide rail assembly 1, a bidirectional connection slider 7 and a camera connection pole 8; the outline of the guide rail assembly 1 is semicircular, and the bidirectional connection slider 7 is provided with a first groove and a second groove, the two-way connection slider 7 is installed on the guide rail assembly 1 through the first groove and the two-way connection slider 7 is slidingly connected with the guide rail assembly 1, and the two-way connection slider 7 is The first groove and the second groove are arranged perpendicular to each other, the camera connecting rod 8 is inserted into the second groove of the two-way connecting slider 7 , and the camera connecting rod 8 points to the center of the guide rail assembly 1 .

[0021] Since the processing of the ellipsoidal guide rail is diff...

specific Embodiment approach 2

[0027] Specific implementation mode two: as figure 1 and figure 2 As shown, the guide rail assembly 1 of this embodiment includes a guide rail body and a guide rail fixing seat, and the lower end of the guide rail body is fixedly mounted on the guide rail fixing seat. With such a design, the guide rail can be fixed, and the circular turntable 2 of the ellipsoid glass bulb detection device can also be installed. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: as figure 1 and figure 2 As shown, the cross section of the guide rail body in this embodiment is rectangular. Designed in this way, it is convenient for the two-way connection slider 7 to slide on the guide rail body, which is convenient for processing. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com