Diesel locomotive rectification chopping phase power module

A technology for diesel locomotives and phase power, which is applied in the directions of converting AC power input to DC power output, converting DC power input to DC power output, and irreversible AC power input to DC power output, etc., which can solve the multi-design cost of power modules And material cost, single function of power module, complex circuit structure connection and other issues, to achieve the effect of simplifying the wiring structure of the main circuit, improving the input power factor, and utilizing the cooling air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

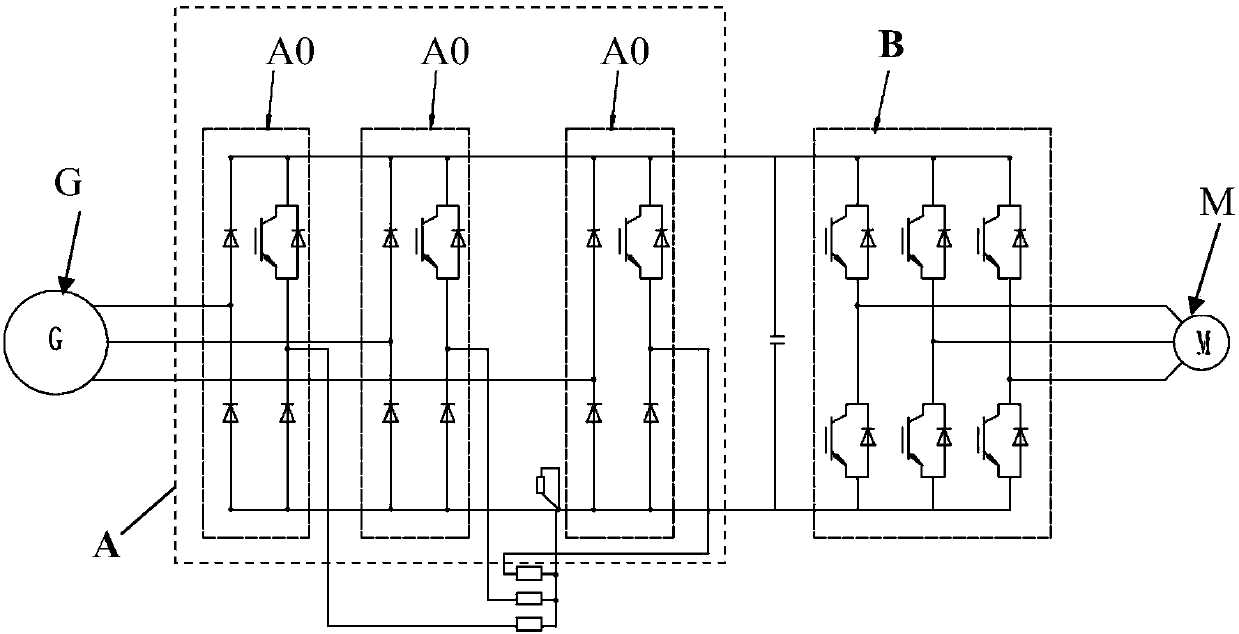

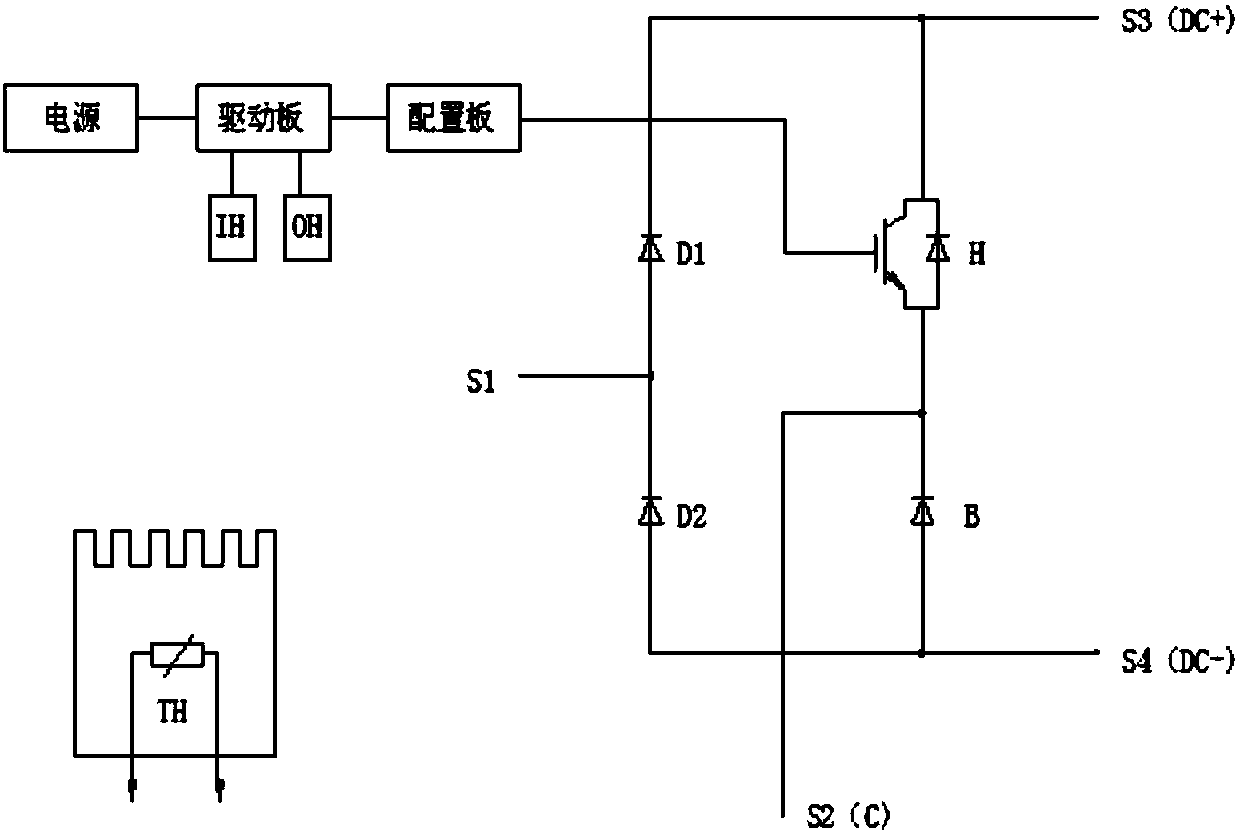

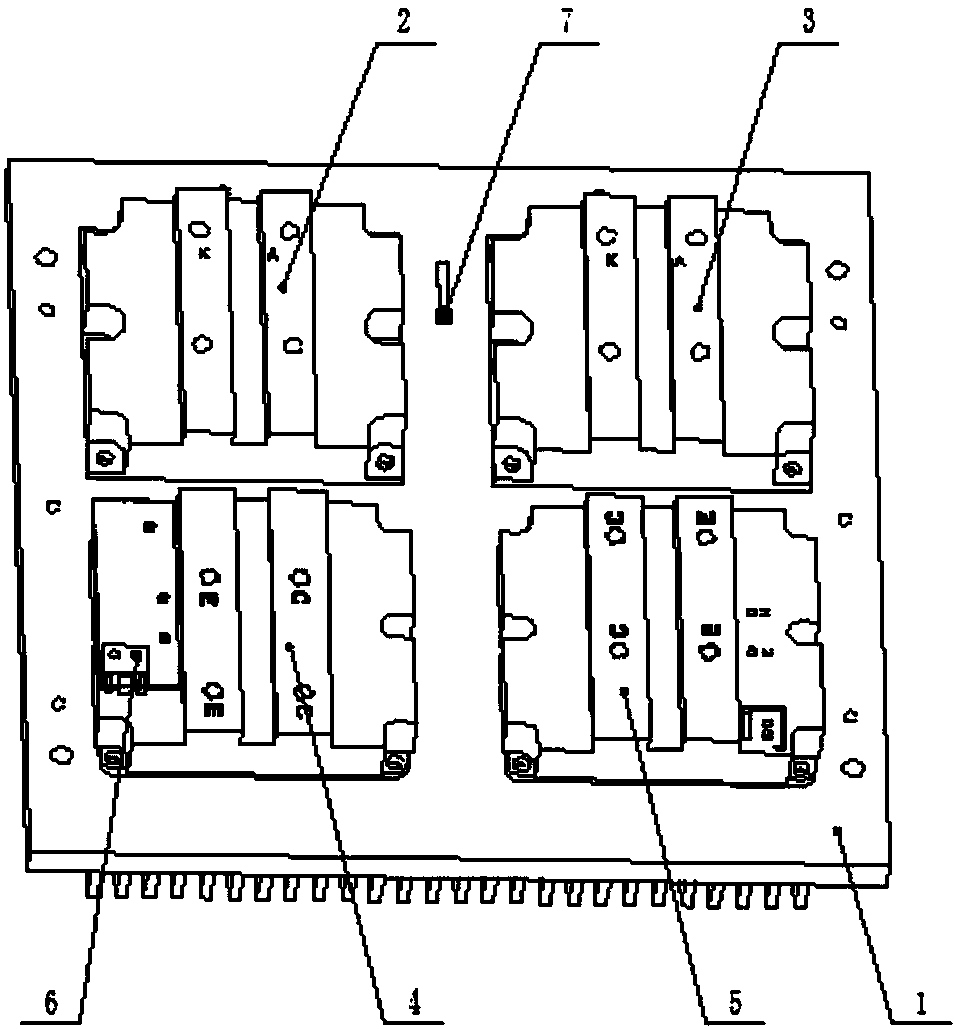

[0030] see figure 1 , The rectifying and chopper phase power module of the diesel locomotive of the present invention includes the main circuit of the traction electric drive system of the diesel shunting locomotive where the rectification and chopper phase power module is located, and the main circuit of the rectification and chopper phase power module. The main circuit of the traction electric transmission system includes the main generator G, the rectification and chopper phase power module A0, and the three-phase inverter module B that shares the DC bus with the rectification and chopper phase power module A0, and also includes the three-phase inverter module B that drives traction motor M; each rectifier and chopper phase power module A0 includes a group of single-phase rectifier bridge arms and a chopper branch; The chopper phase power module A0 is completed; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com