Power compensation-based sensorless control system and method for synchronous reluctance motor

A technology of synchronous reluctance motor and power compensation, which is applied in the direction of control system, motor control, vector control system, etc., and can solve problems such as limitation and large noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

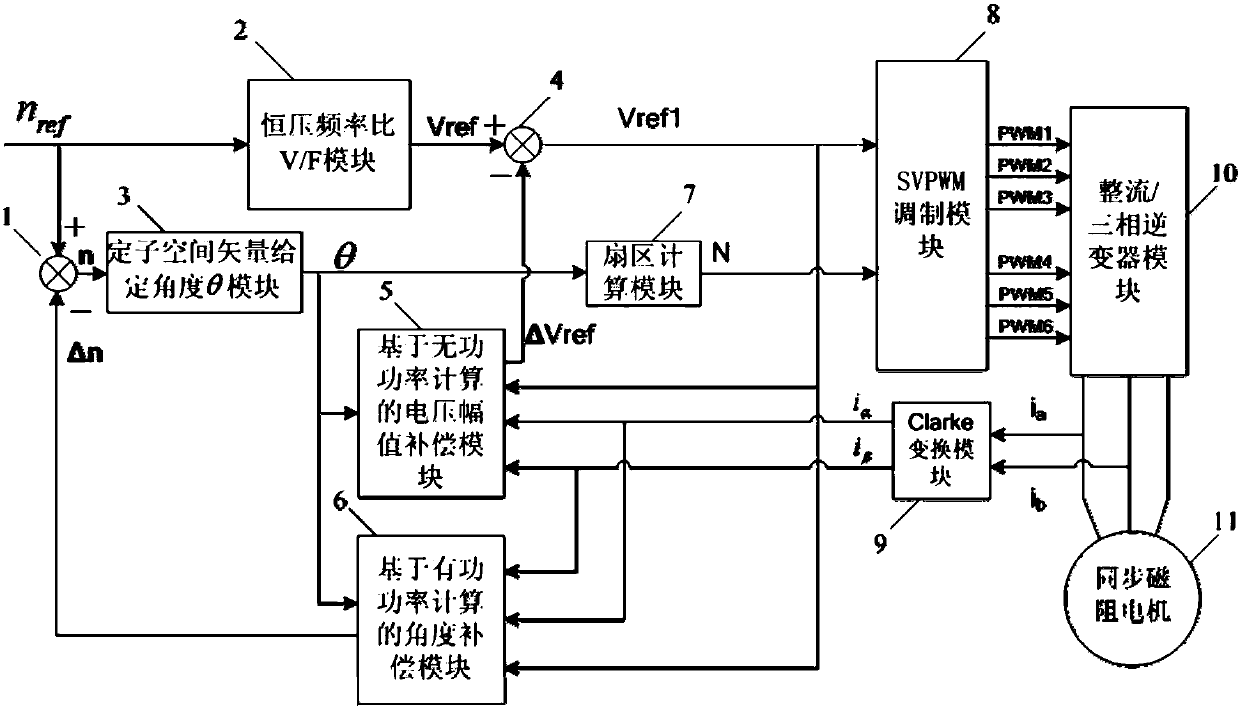

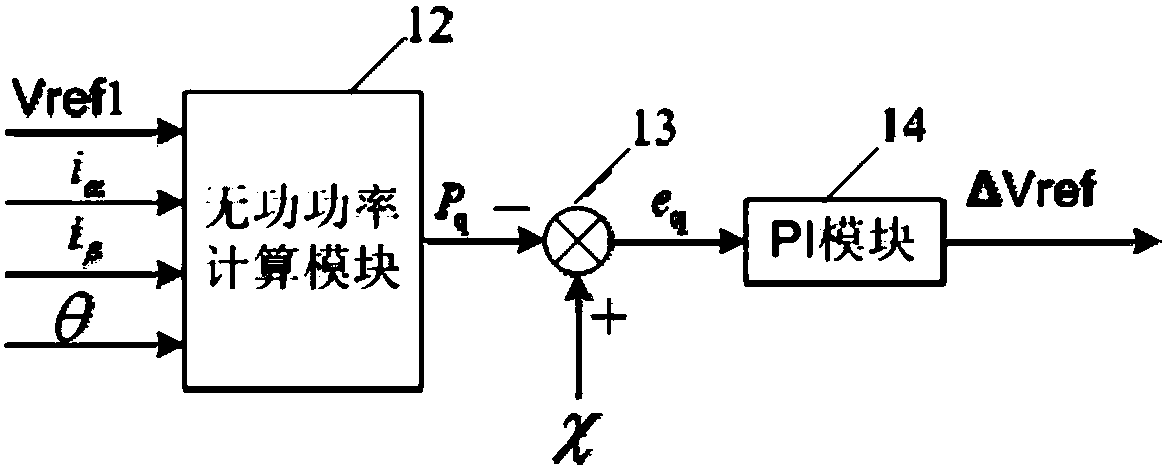

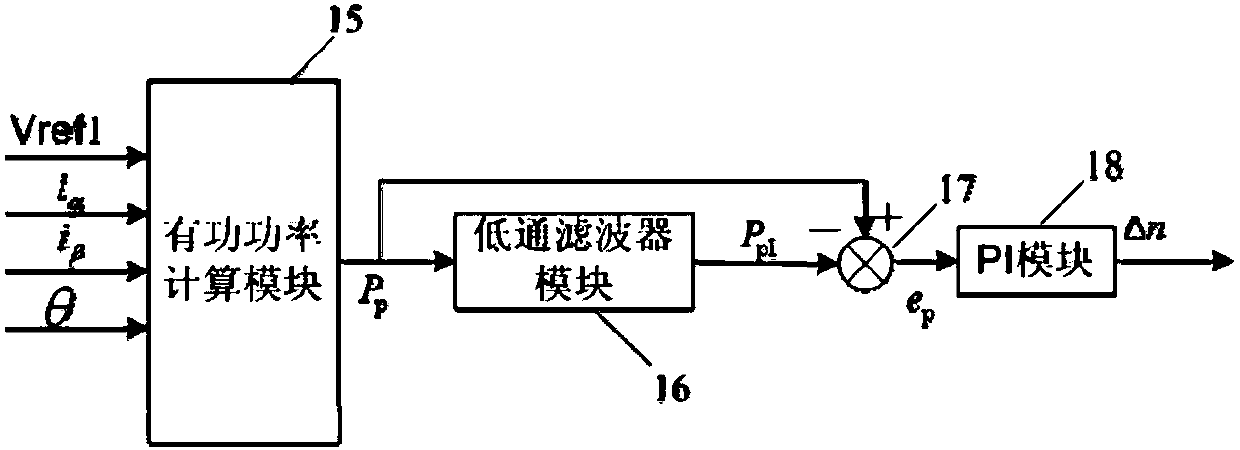

[0070] Embodiment 1. A sensorless control system for synchronous reluctance motors based on power compensation, such as figure 1 As shown in -4, it includes the first subtractor 1, the constant voltage frequency ratio V / F module 2, the stator voltage space vector given angle θ module 3, the second subtractor 4, and the voltage amplitude compensation module based on reactive power calculation 5. Angle compensation module 6 based on active power calculation, sector calculation module 7, SVPWM modulation module 8, Clarke transformation module 9, rectification / three-phase inverter module 10 and synchronous reluctance motor 11.

[0071] The signal connection relationship of the present invention is as follows:

[0072] Synchronous reluctance motor 11 outputs two-phase actual current i a i b to Clarke transform module 9;

[0073] Clarke transformation module 9 according to the input two-phase actual current i a i b , the current component i in the static two-phase coordinate sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com