Method for producing a milk-based product with reduced plasmin-activity

A technology of plasminase activity and dairy products, applied in dairy products, other dairy products, biochemical equipment and methods, etc., can solve problems such as milk bitterness or structural defects, and achieve the effect of simple method and good sensory properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

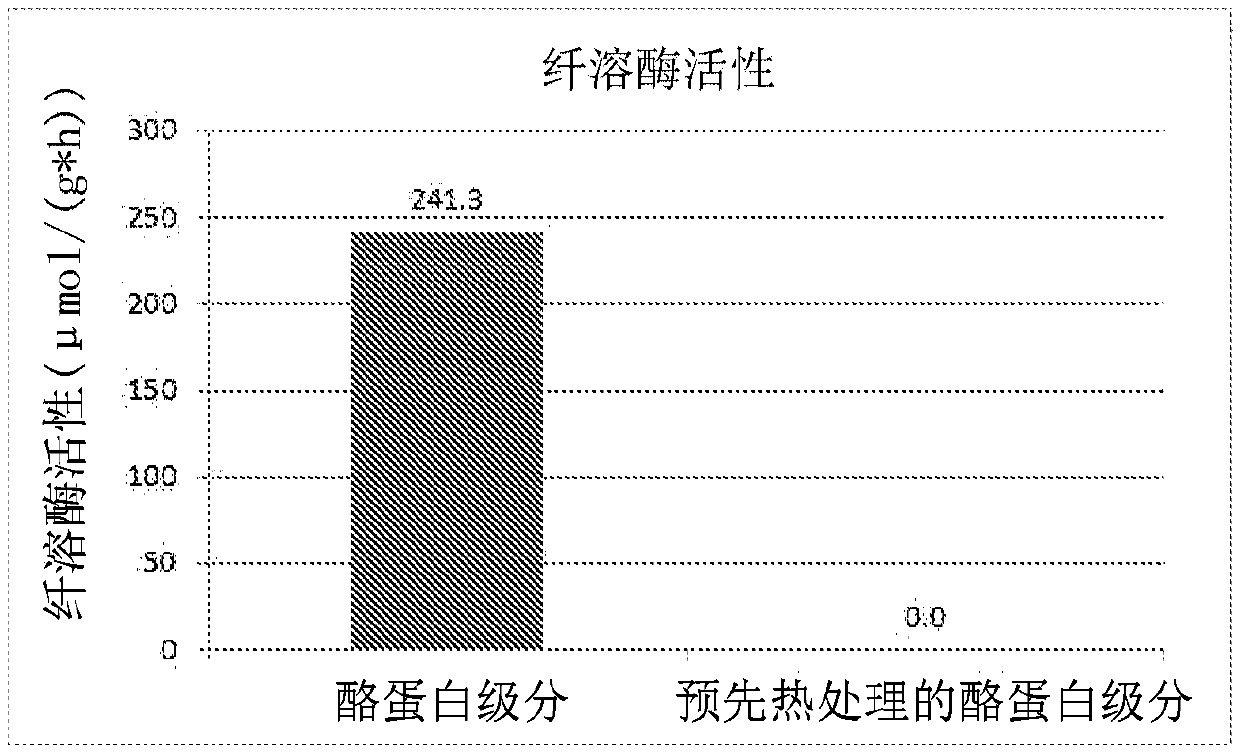

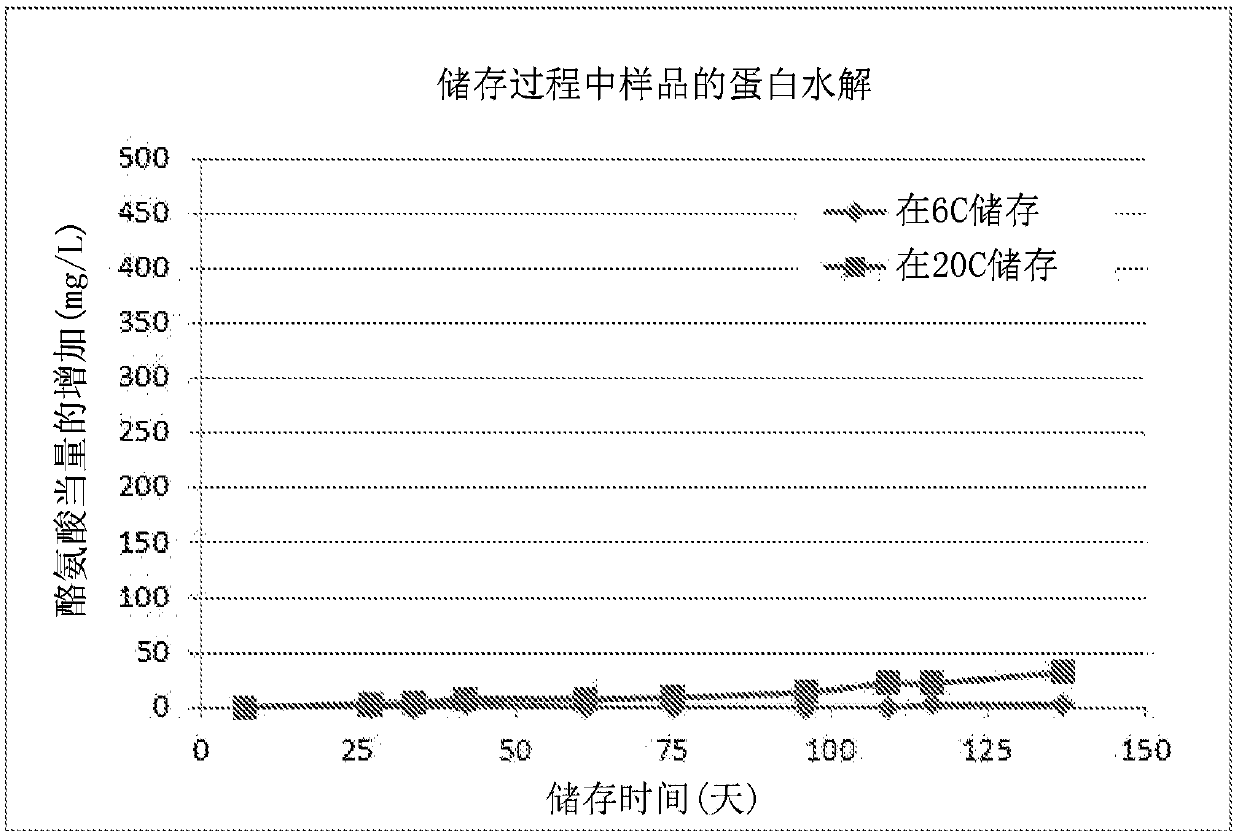

[0053] In another object, the present invention provides a method for the preparation of dairy products with reduced plasmin activity, said method comprising the steps of:

[0054] - providing a casein product having a whey protein content of less than 20% by weight, in particular at most about 18% by weight, more in particular at most about 14% by weight, more particularly In particular up to about 12% by weight, more especially up to about 6% by weight,

[0055] - heat-treating said casein preparation at a temperature of from about 72°C to about 95°C, in particular from about 80°C to about 95°C, thereby providing a heat-treated casein preparation,

[0056] - Providing a dairy product with reduced plasmin activity comprising a heat-treated casein product.

[0057] The casein product used in the method for producing a dairy product may be obtained in any suitable way. In one embodiment, the casein product is a casein concentrate obtained by separating casein and whey protein...

Embodiment 1

[0080] Example 1. Milk separation by membrane filtration

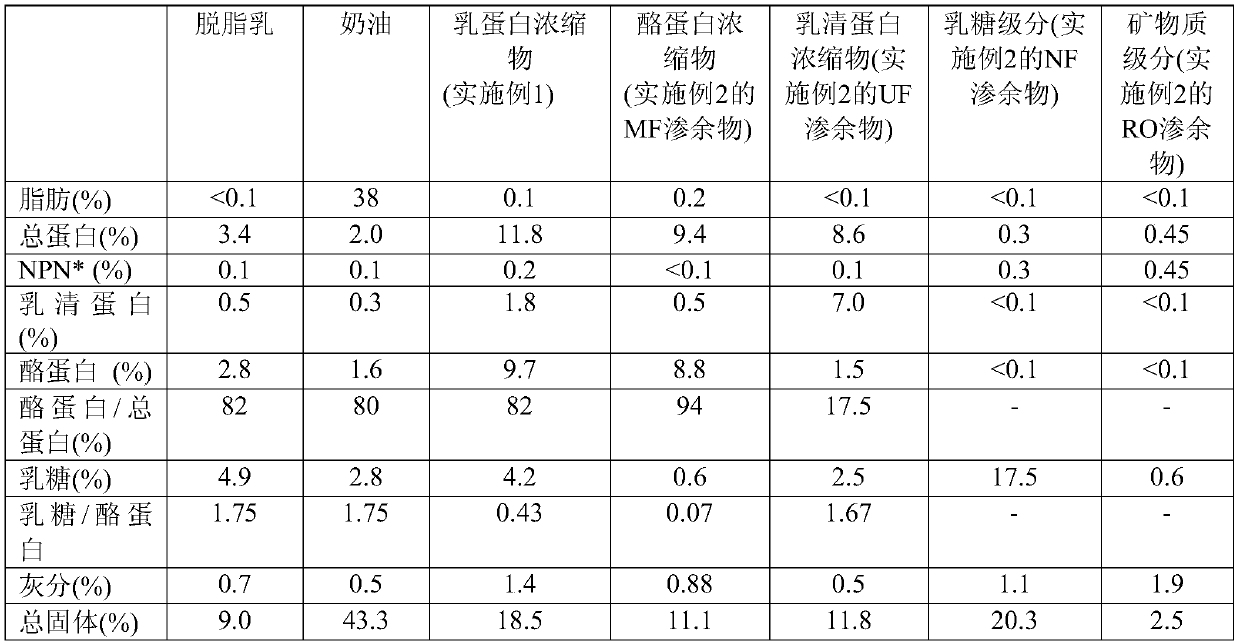

[0081] The skim milk was ultrafiltered at about 10°C with a volume concentration factor (VCR) of 3.7. The membrane used for ultrafiltration was Koch HKF131 from Koch Membrane Systems. Table 1 shows the composition of the skim milk and the milk protein concentrate obtained (ie the ultrafiltration retentate).

Embodiment 2

[0082] Example 2. Milk separation by membrane filtration

[0083] The skim milk is microfiltered at a temperature of 10°C to 15°C at a pressure of less than 1.5 bar, thereby concentrating the casein in the microfiltration retentate. The membrane used in microfiltration was Synder FR from Synder Filtration, Inc. Skim milk is first microfiltered at a concentration factor of about 4. Microfiltration was then continued by diafiltration, wherein tap water was added to the resulting microfiltration retentate in an amount equal to the amount of the resulting retentate. Microfiltration is continued until an equivalent amount of exudate obtained compared to the amount of water added is discharged. The diafiltration step was repeated twice. The permeates from the two diafiltration steps were combined and the combined mixture was subjected to ultrafiltration with a Koch HKF 131 membrane at a temperature of 10°C to 15°C to concentrate the whey protein in the ultrafiltration retentate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com