Method for removing humic substances from aqueous alkaline solution

A humus and alkaline technology, applied in the field of humus, can solve problems such as high inorganic sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The present invention may be better understood by the following examples, which are provided for illustration only and should not be construed as limiting the invention.

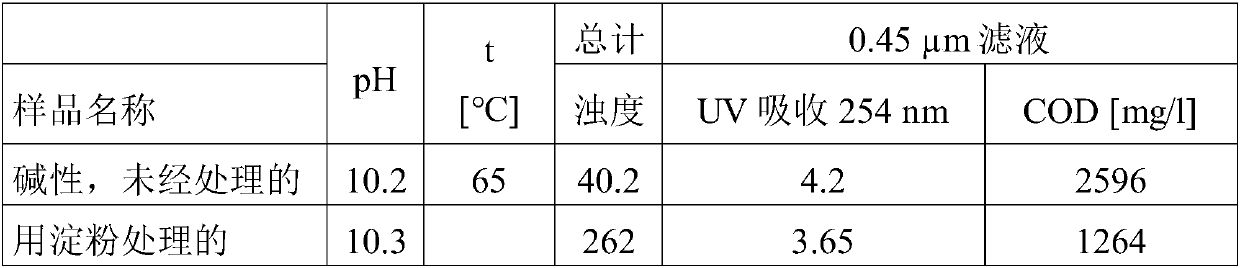

[0032] Wastewater from bleaching contains humic substances such as dissolved lignin. Its removal by biological treatment is considered difficult. In this work, the precipitation of lignin using highly cationic starch according to the invention was investigated.

[0033] exist Coagulation acceleration and flocculation tests for COD removal were carried out in the mill laboratory. Tests were performed with fresh wastewater samples from the alkaline bleach filtrate line. The wastewater sample temperature was 65°C.

[0034] The batch size was 500ml in a microflocculator. The operation of the flocculator is as follows:

[0035] 1) Mix quickly (350rpm), add cationic starch coagulant (2000ppm) at the beginning, and finally add flocculant (2ppm);

[0036] 2) slow mixing (40rpm), and

[0037] 3) Settl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com