Polyether-polysiloxane block copolymer composition, surfactant and foam stabilizer including same, polyurethane foam-forming composition, cosmetic, and preparation method thereof

A technology of polysiloxane block and polyurethane foam, which is applied in the fields of cosmetic raw materials and cosmetics, polyurethane foam-forming compositions, foam stabilizers, polyurethane foam, and surfactants. Popularity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

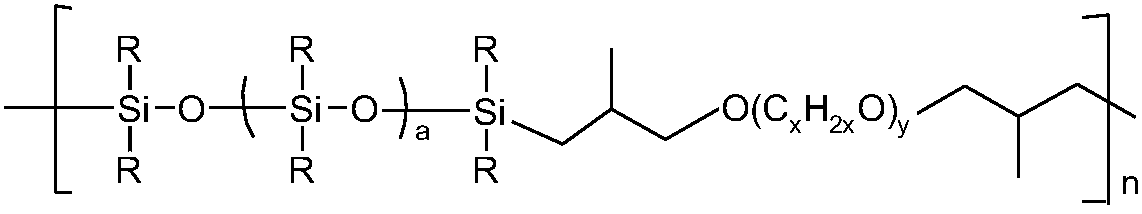

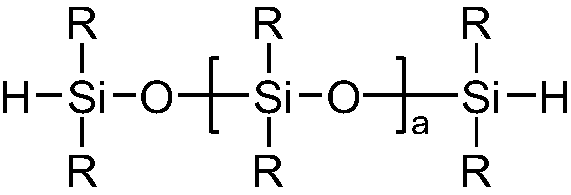

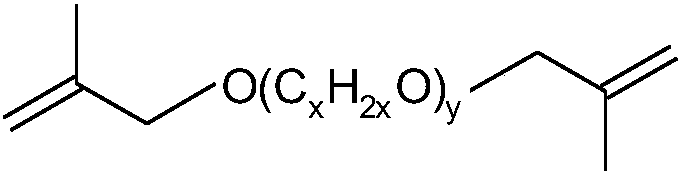

[0251] In the 1L reactor, the average combined formula M H D. 20 m H Represented methyl hydrogen polysiloxane 75.25g, with the average combined formula CH 2 =C(CH 3 )CH 2 -O(C 2 h 4 O) 33 (C 3 h 6 O) 25 -CH 2 -C(CH3 )=CH 2 174.75 g of the indicated bismethallyl polyether, 250 g of dipropylene glycol monobutyl ether (BDPG) and 0.25 g of natural vitamin E were heated to 80-90°C while stirring under nitrogen flow. 0.56 g of the IPA solution (Pt concentration: 0.45% by weight) of a platinum-2,4,6,8-tetramethyl-2,4,6,8-tetravinyltetrasiloxane complex was added and reacted for 2.5 hours. Next, 1 g of the reaction liquid was collected and confirmed by the alkali decomposition gas generation method, and the reaction was completed. Thus, a 50:50 ratio containing at least the average combined formula

[0252] [chemical formula 6]

[0253]

[0254] (Here, a=20, x1=33, y1=25, n=6)

[0255] A liquid polyether-polysiloxane block copolymer composition of linear organopolys...

Embodiment 1-2

[0257] Except having replaced BDPG with propylene glycol monobutyl ether (BPG), it experimented similarly to Example 1-1. Operations such as reactivity in the synthesis reaction of the linear organopolysiloxane-polyether block copolymer are the same as in Example 1-1.

Embodiment 2-1

[0259] In the 1L reactor, the average combined formula M H D. 20 m H Represented methyl hydrogen polysiloxane 85.55g, with the average combined formula CH 2 =C(CH 3 )CH 2 -O(C 2 h 4 O) 33 (C 3 h 6 O) 25 -CH 2 -C(CH 3 )=CH 2 164.45 g of the indicated bismethallyl polyether, 250 g of dipropylene glycol monobutyl ether (BDPG) and 0.25 g of natural vitamin E were heated to 80-90°C while stirring under nitrogen flow. 0.056 g of an IPA solution (Pt concentration: 4.5% by weight) of a platinum-2,4,6,8-tetramethyl-2,4,6,8-tetravinyltetrasiloxane complex was added and reacted for 3 hours. Next, 1 g of the reaction liquid was collected and confirmed by the alkali decomposition gas generation method, and the reaction was completed. Thus, a 50:50 ratio containing at least the average combined formula

[0260] [chemical formula 7]

[0261]

[0262] (Here, a=20, x1=33, y1=25, n>10)

[0263] A liquid polyether-polysiloxane block copolymer composition of linear organopolys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com