Coated paper, coated base material, and method of evaluating property of ink drying

A technology of coating substrates and coated papers, applied in papermaking, paper testing, pigmented coatings, etc., to achieve the effects of excellent paper alignment and accurate ink drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0096] (1) Preparation of base paper

[0097] Regarding the base paper, as already mentioned. The base paper can be produced by a known papermaking method.

[0098] For example, it can be carried out using a fourdrinier paper machine including a top wire, etc., an on topformer (on topformer), a gap former, a cylinder paper machine, and a combination of a fourdrinier paper machine and a cylinder. Cardboard paper machine for paper machine, Yankee dryer paper machine, etc. The pH at the time of papermaking may be any of acidic, neutral, and alkaline, and is preferably neutral or alkaline. The papermaking speed is not particularly limited.

[0099] (2) Smoothing treatment of base paper

[0100] Before applying the pigment coating solution to the obtained base paper, it is preferable to subject the base paper to a smoothing treatment using various calendering devices. As the said calendering apparatus, the calendering apparatus normally used, such as a super calender and a sof...

Embodiment 1-1

[0215] Use heavy calcium carbonate slurry (manufactured by IMERYS, trade name: Carbital 97, the ratio of particles with a particle diameter of 2 μm or less: 97%) 55 parts by weight (solid content) and 2nd grade clay (manufactured by IMERYS, trade name: KCS, the particle diameter is the proportion of particles below 2 μm: 85%) 45 parts by weight (solid content) as a pigment, in which 4 parts by weight of styrene-butadiene copolymer latex, oxidized starch (manufactured by Japan Corn Starch Co., Ltd., A product name: SK200) 6 parts by weight was used as a binder, and water was further added to obtain a pigment coating liquid 1 having a solid content concentration of 66% by weight.

[0216] As the base paper, prepare 100% by weight of chemical pulp, 13% by weight of light calcium carbonate as a filler, and a density of 0.73g / cm 3 , weight 98g / m 2 premium paper. Pigment coating solution 1 was applied to the base paper at a dry coating weight of 15.0 g / m per side using a knife coa...

Embodiment 1-2

[0218] Use 55 parts by weight (solid content) of causticized light calcium carbonate slurry 1 (D50=1.02 μ m) and 2 grade clay (manufactured by IMERYS, trade name: KCS, D50=4.9 μ m) 45 parts by weight (solid content) as The pigment was mixed with 4 parts by weight of styrene-butadiene copolymer latex 1 (manufactured by A&L Corporation, trade name: PB1537), and 6 parts by weight of oxidized starch (manufactured by Japan Corn Starch Co., Ltd., trade name: SK200) as a binder, Water was further added to obtain a pigment coating liquid 1' having a solid content concentration of 66% by weight.

[0219] A coated printing paper was obtained in the same manner as in Example 1-1, except that the pigment coating liquid 1' was used instead of the pigment coating liquid 1.

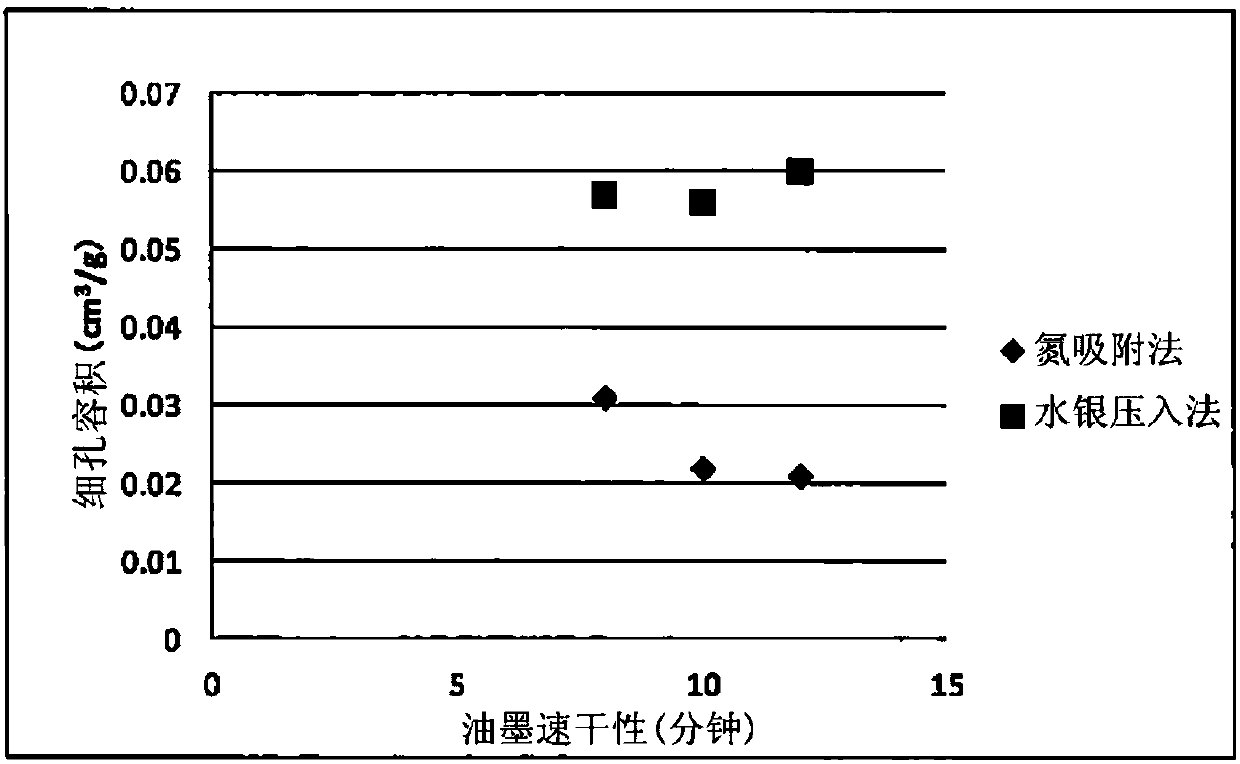

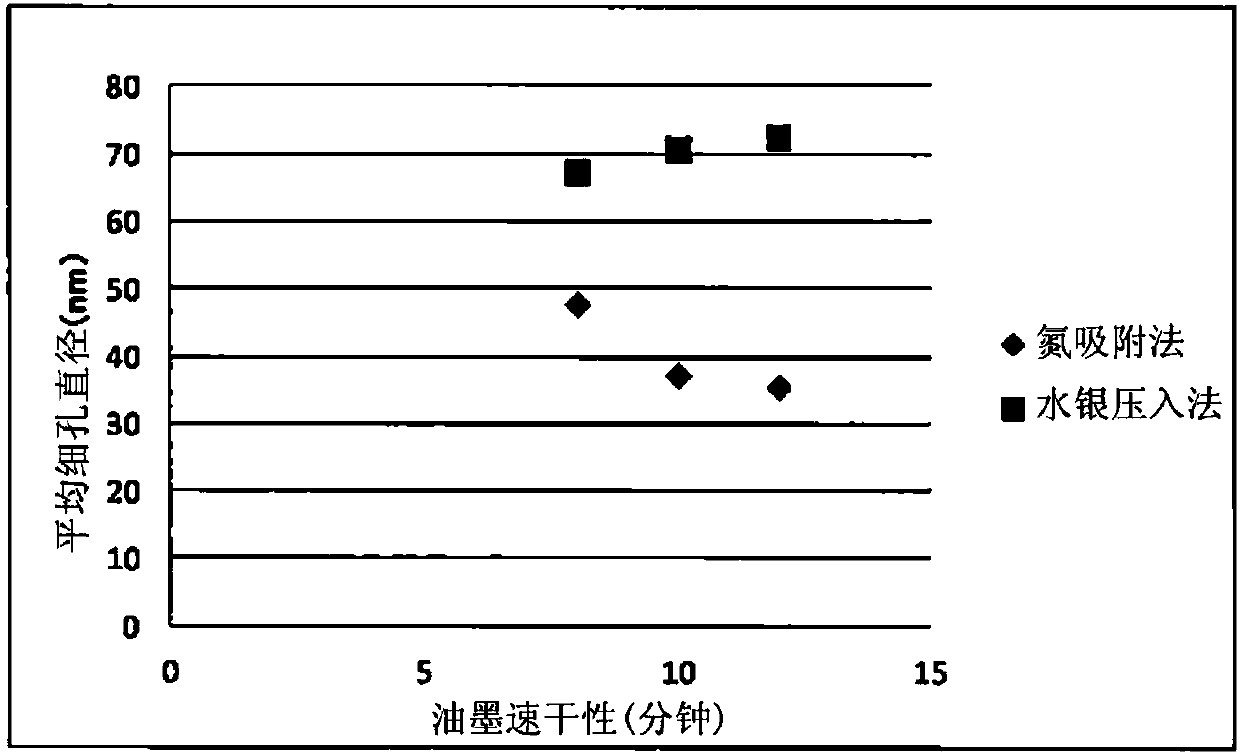

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com