Mixed berry granules added to normal-temperature yogurt and preparation method of mixed berry granules

A technology for fruit and yogurt, which is applied in milk preparations, applications, dairy products, etc., can solve problems such as the integrity of fruit particles, adverse effects on taste and flavor, and achieve excellent taste, small fruit breakage rate, and good product condition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

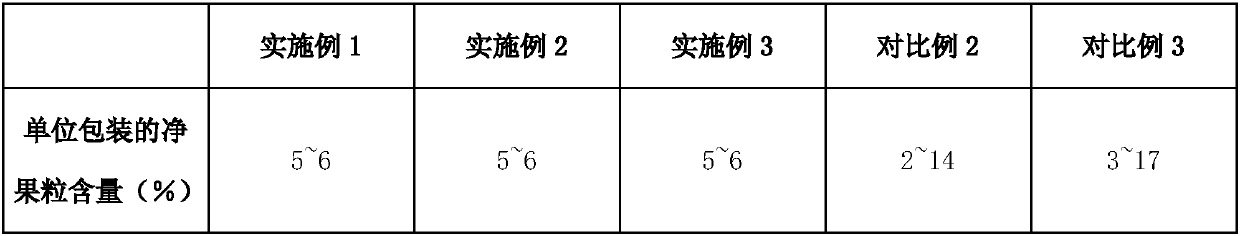

Examples

Embodiment 1

[0033](1) Ingredients: Dissolve 20% white granulated sugar with water (6.8%) at 50°C, dry mix the remaining 20% white granulated sugar with 0.2% stabilizer, then slowly add 50°C sugar water to hydrate for 20 minutes. Then add 50% blueberry, cranberry, blackberry and black currant particles, the ratio is 1:1:1:1, about 75% of all kinds of berries have a particle size of 7mm, then add 1% food flavor, continue to hydrate Stir for 20 minutes at a stirring rate of 4 rpm, and finally add 2% acidity regulator to adjust the pH of the jam to 3, and transport it to a temporary storage tank by a screw pump for storage at 4°C;

[0034] (2) The mixed berry particles after the acid adjustment in the above step (1) are sterilized by a tubular sterilizer, preheated to a temperature of 10°C through a tubular heat exchanger, and the tubular sterilizing condition is 85°C for 120s, and then sterilized The final discharge temperature is 20°C, and under this condition, it is filled into aseptic t...

Embodiment 2

[0036] (1) Ingredients: Dissolve 15% white granulated sugar with water (9.2%) at 60°C, dry mix the remaining 15% white granulated sugar with 0.3% stabilizer, then slowly add 60°C sugar water to hydrate for 20 minutes. Then add 60% blueberry, cranberry and blackberry particles, the ratio is 1:1:1, about 70% of all kinds of berries have a particle size of 5mm, continue to hydrate and stir for 10min, the stirring speed is 6rpm, and finally add 0.5% The acidity regulator adjusts the pH of the jam to 6, and transports it to a temporary storage tank through a screw pump for storage at 10°C;

[0037] (2) The mixed berry particles after the acid adjustment in the above step (1) are sterilized by a tubular sterilizer, preheated to a temperature of 15°C through a tubular heat exchanger, and the tubular sterilizing condition is 121°C for 30 seconds, and then sterilized The final discharge temperature is 30°C, and under this condition, it is filled into aseptic ton tanks or aseptic bags f...

Embodiment 3

[0039] (1) Ingredients: Dissolve 17.5% white granulated sugar with water (8.25%) at 55°C, dry mix the remaining 17.5% white granulated sugar with 0.25% stabilizer, then slowly add 55°C sugar water to hydrate for 15 minutes. Then add 55% blueberry, cranberry and black currant particles, the ratio is 1:1:1, about 80% of the particles of various berries have a particle size of 6mm, then add 0.5% blueberry essence, continue to hydrate and stir for 15 minutes, stir The speed is 5 rpm, and finally add 1% acidity regulator to adjust the pH of the jam to 5, and transport it to a temporary storage tank by a screw pump for storage at 8°C;

[0040] (2) The mixed berry particles after the acid adjustment in the above step (1) are sterilized by a tubular sterilizer, preheated to a temperature of 12°C through a tubular heat exchanger, and the tubular sterilizing condition is 115°C for 60 seconds, and then sterilized The final discharge temperature is 25°C, and under this condition, it is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com