Ultrasonic scalpel bit, ultrasonic vibration transmission module and ultrasonic haemostatic and cutting system

A technology of ultrasound and cutter head, which is applied in the field of medical devices, can solve the problems of poor effect, achieve the effect of increasing the effective length, improving the hemostasis effect, and improving the characteristics of amplitude and pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

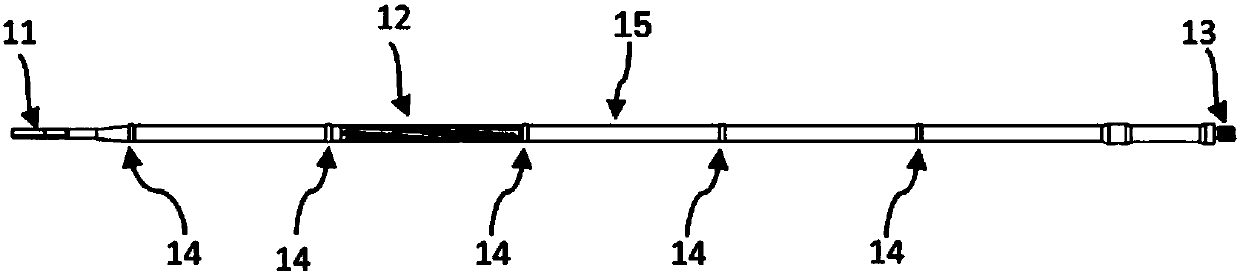

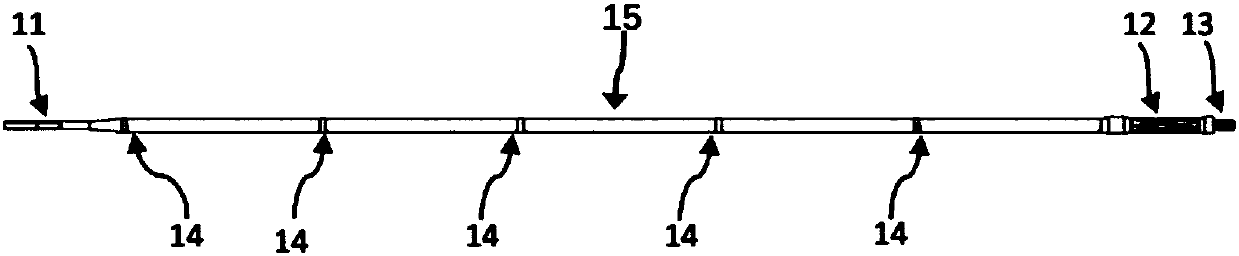

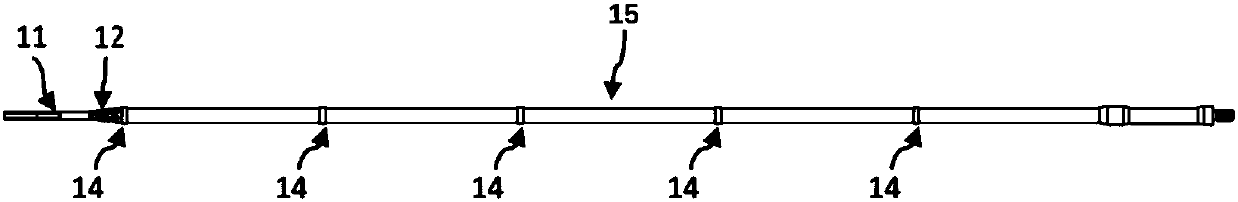

[0036] This embodiment discloses an ultrasonic cutter head 101, the structure of which is shown in Figure 1(a), Figure 1(b), Figure 1(c), Image 6 and Figure 8 As shown, it includes an ultrasonic tool tip 11, a waveguide 15, a connecting portion 13 and a vibration node boss 14, the ultrasonic tool tip 11 is arranged on the front side of the waveguide 15, the connecting portion 13 is arranged on the rear side of the waveguide 15, and the vibration node boss 14 Provided on the waveguide 15 , the ultrasonic blade tip 11 is bent laterally at the tip, and a vibration guide groove 12 is provided on the waveguide 15 . Among the above components, the ultrasonic blade tip 11 is used for cutting and hemostasis of the biological tissue 401, the vibration guide groove 12 is used to convert the longitudinal vibration of the ultrasonic transducer into longitudinal and torsional composite vibration, and the connecting portion 13 is used to connect the ultrasonic blade. The head is connecte...

Embodiment approach 2

[0042] like Figure 8 As shown, this embodiment is different from the first embodiment in that the vibration guide groove is arranged on the waveguide 15 , and the vibration guide groove 12 of the ultrasonic tool head 101 is arranged on the ultrasonic tool tip 11 and is located at the rear end of the ultrasonic tool tip 11 . department. The above arrangement can further reduce the frictional heat generation effect between the vibration guide groove 12 and the lubricating cylinder 108 .

Embodiment approach 3

[0044] On the basis of the first or second embodiment, the present embodiment further defines the shape of the ultrasonic tool tip 11 of the ultrasonic tool head 101 . That is, the ultrasonic tip 11 includes a tapered width feature in addition to being laterally curved at the tip. For example, the gradient width feature can be a trapezoid gradient width feature, the top view of which is shown in Figure 9(a), the front end of the ultrasonic tool tip 11 has a larger front end and a narrower rear end width; its side view is shown in Figure 9(b) Show. The above design can change the mass distribution law of the ultrasonic blade tip 11 along the vibration axis, thereby improving the amplitude and pressure distribution characteristics of the ultrasonic blade tip 11 along the vibration axis, and further improving the temperature of the ultrasonic blade tip 11 during coagulation or cutting of the biological tissue 401. Uniformity and improved hemostasis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com