Metal-nitrogen carbon material with atomic-scale dispersed metal as well as preparation method and application thereof

A nitrogen-carbon material, atomic-level technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the difficulty of further improvement, low efficiency of metal nitrogen-carbon composite materials, expensive ligand materials, etc. problems, to achieve the effect of simple and easy reaction operation, low cost, low toxicity and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

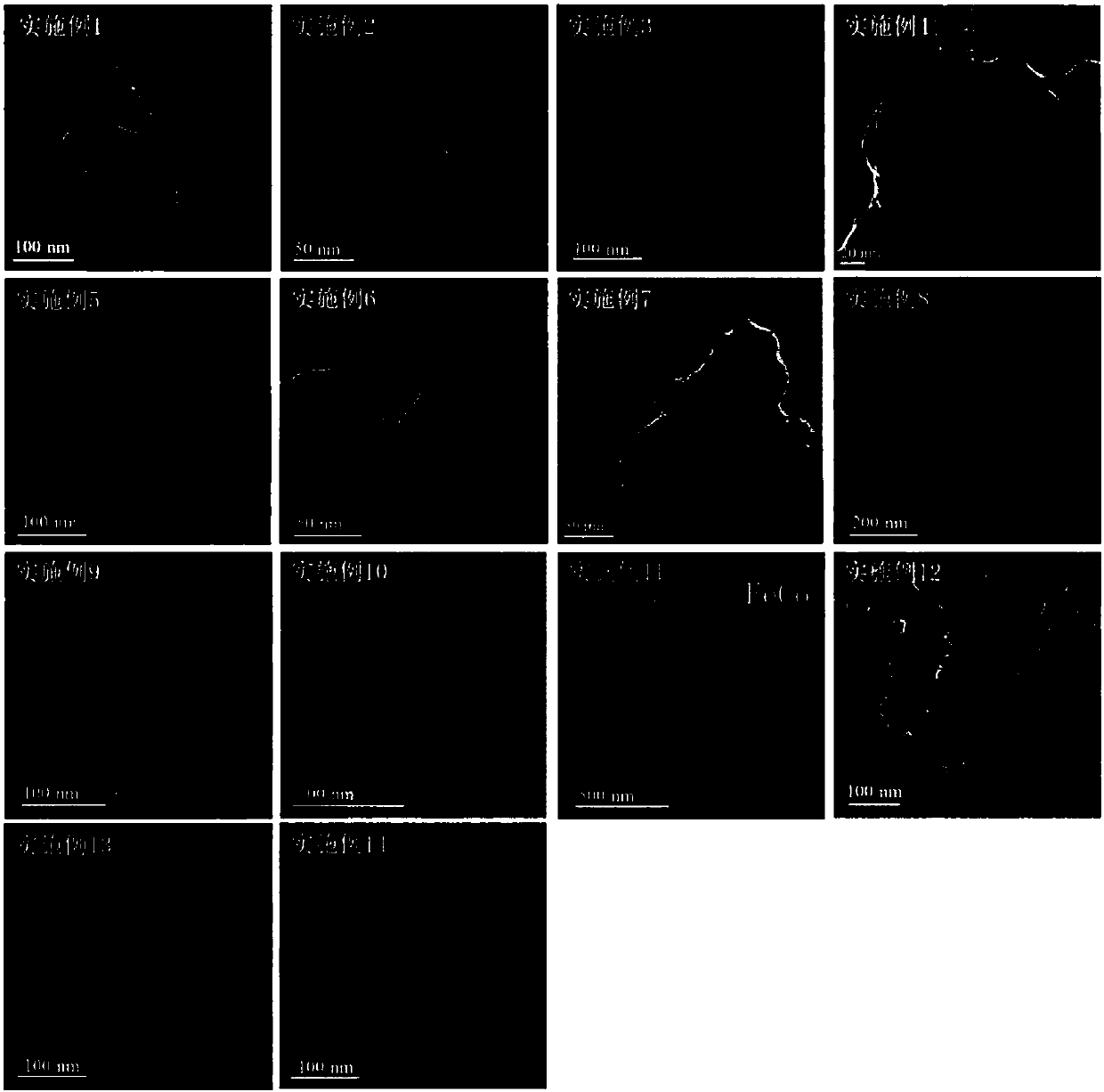

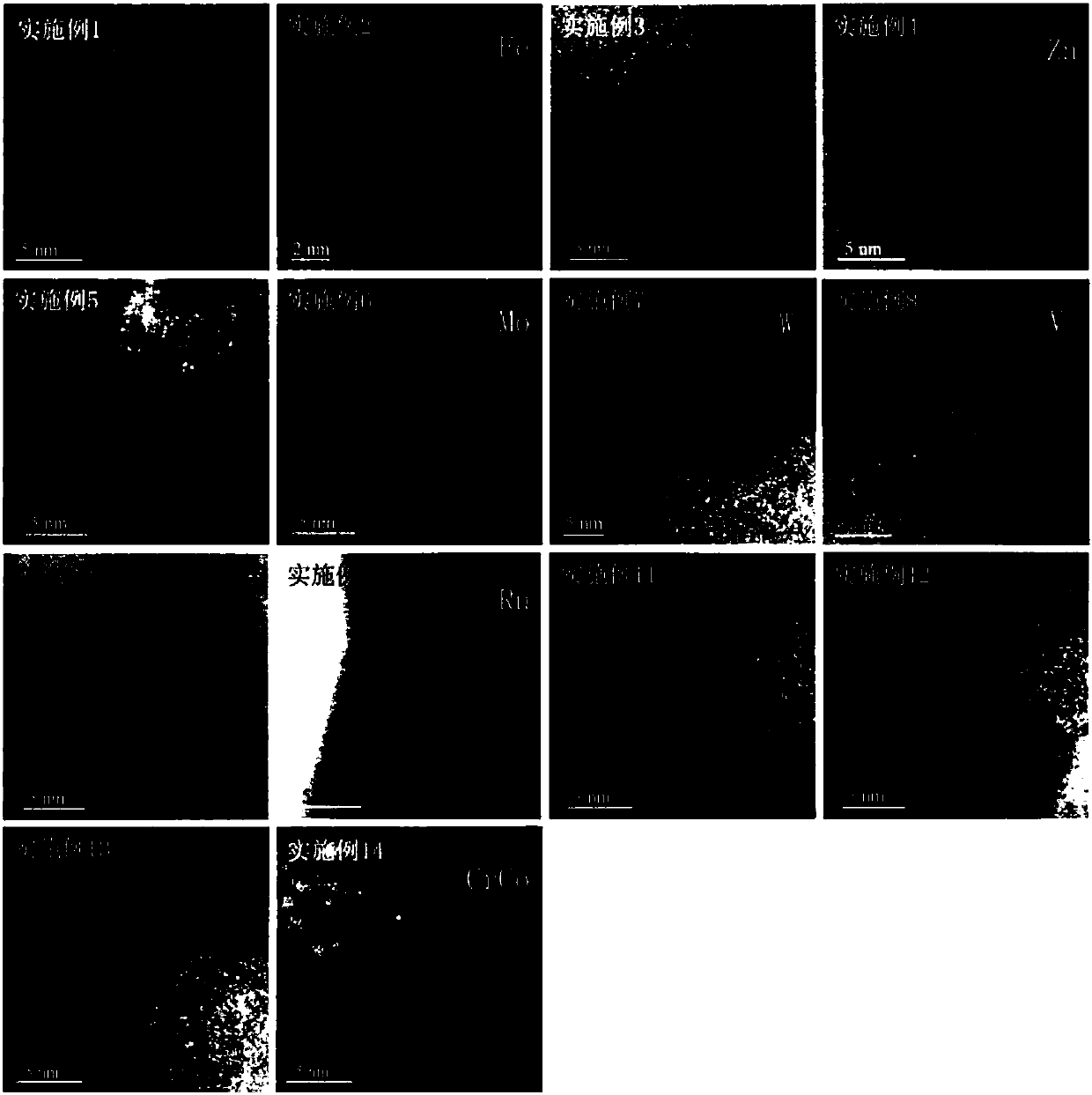

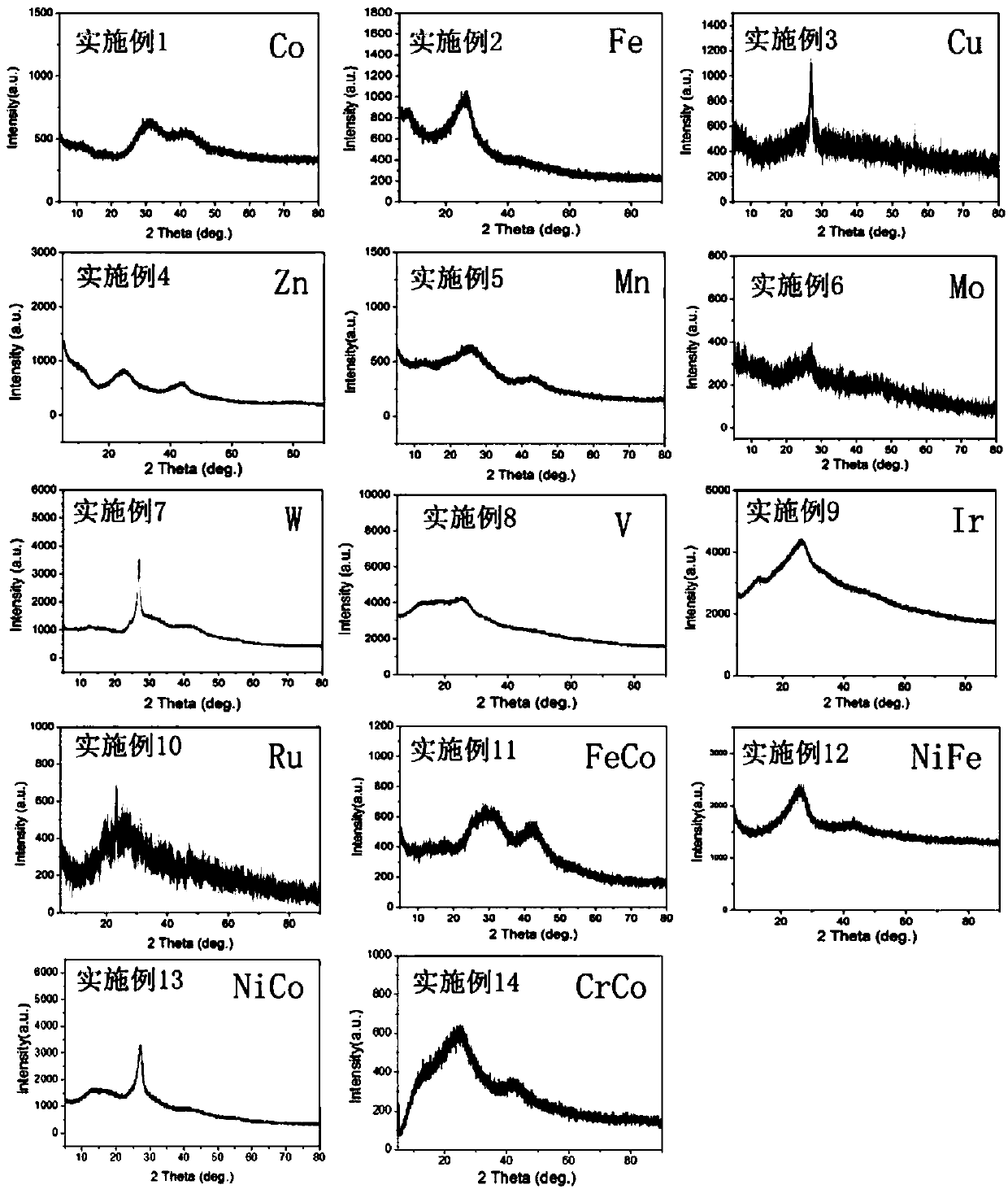

[0038] According to the following Table 1, a certain amount of metal salts were dissolved in 30mL formamide, ultrasonically dispersed until transparent, and then placed in a polytetrafluoroethylene reactor with a volume of 40.0mL, at the reaction temperature shown in Table 1 react with time. After the reaction, cool down naturally, take out the solid-liquid mixture, separate the solid and liquid by centrifugation, dry the solid in an oven at 60°C, and collect the dry powder, which is the metal-nitrogen-carbon material precursor in which the metal is dispersed at the atomic level. Wherein the precursor shown in embodiment 1-14 is carried out the mensuration of nitrogen content and metal content and pickling elution rate, wherein with the dilute sulfuric acid of 1mol / L after target product is soaked 2h, measure metal elution rate, result are shown in Table 1.

[0039] Then each precursor is roasted under the protection of argon at the roasting temperature and time shown in Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com