Integrated mounting structure of electric vehicle driving system

A technology of drive system and installation structure, applied in electric power unit, power unit, control unit, etc., can solve the problem of unfavorable three-in-one structure installation and maintenance, front cabin beam routing, complicated pipeline, and scattered drive system installation structure. and other problems, to achieve the effect of good shock absorption, convenient layout, and improved integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

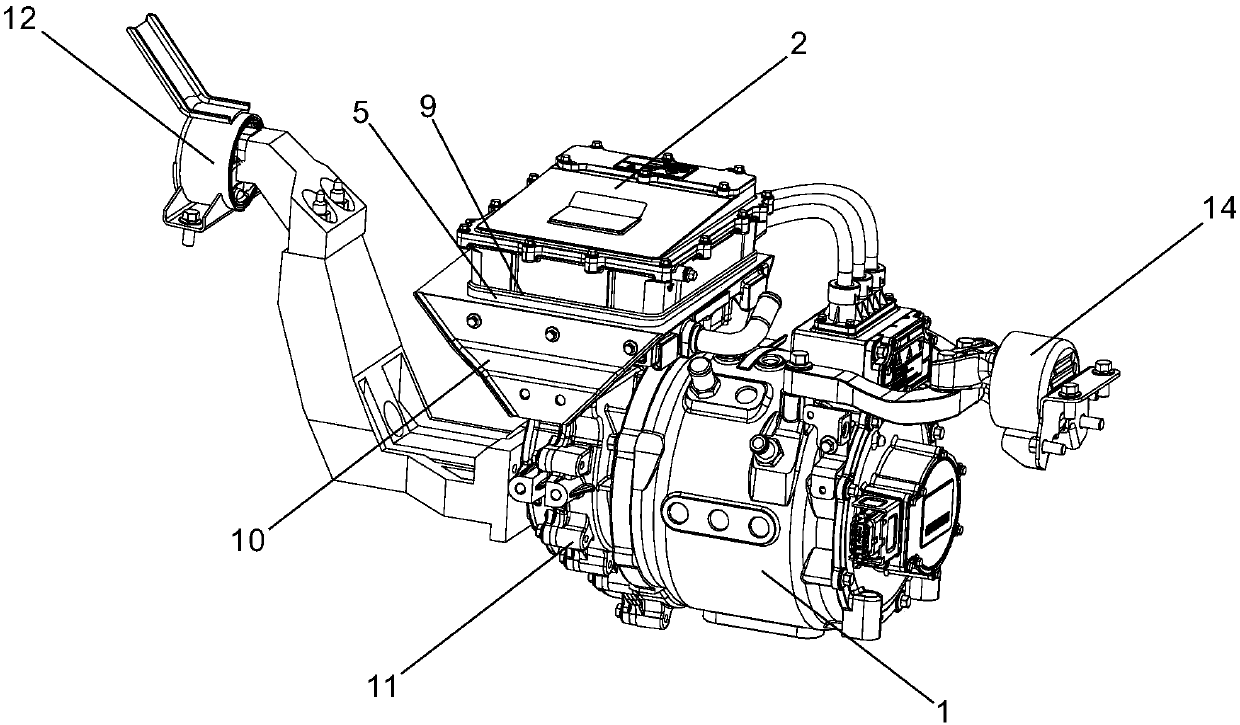

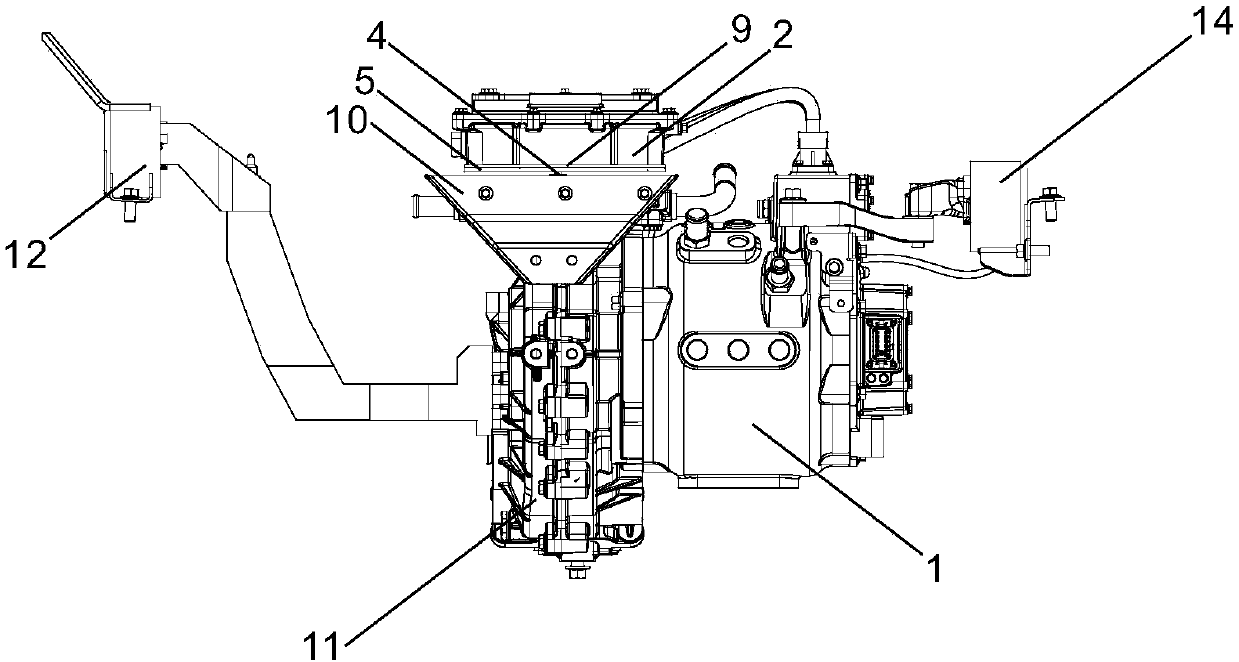

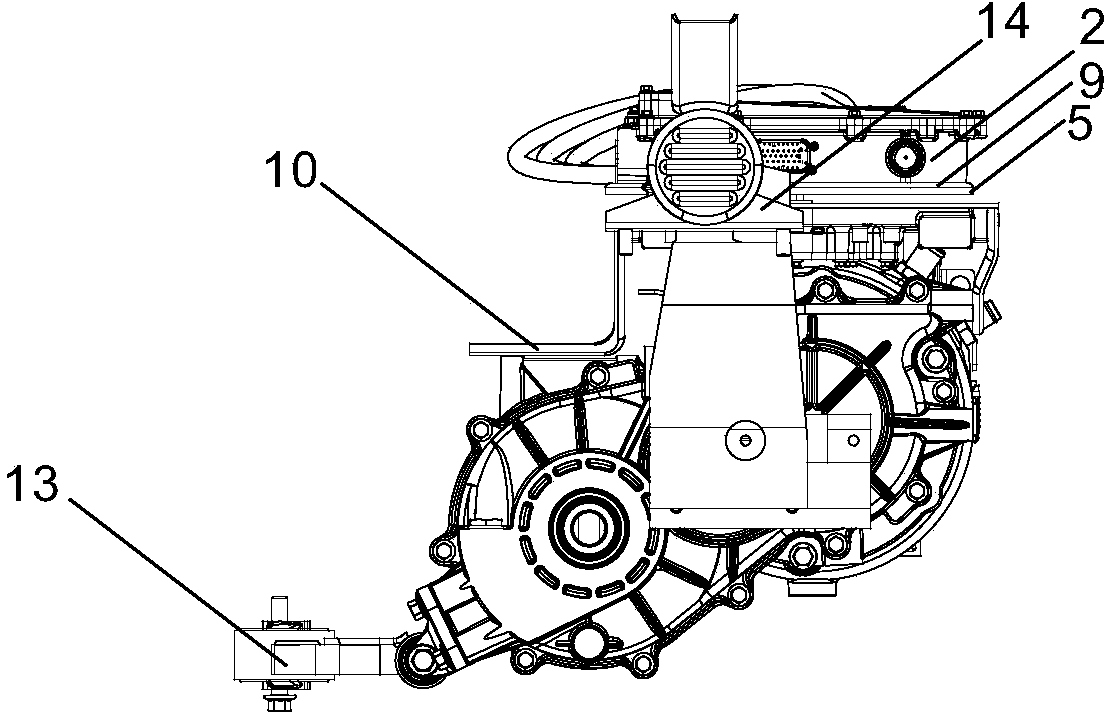

[0026] Such as Figure 1 to Figure 4As shown, an electric vehicle drive system integrated installation structure includes a motor 1 and a motor controller 2. A controller bracket 10 is installed on the motor 1 shell through bolts. The controller bracket 10 includes an integrally bent support plate and a fixed Feet, the fixed feet are located at both ends of the support plate, one end of the fixed foot is a vertical flat plate, fixed to the side of the motor 1 by bolts, the other end of the fixed foot is L-shaped, fixed to the top of the motor 1 by bolts, and the fixed feet support the controller bracket 10 The plate is suspended in the air, the support plate is provided with internal threads, and a shock absorber 3 is fixed on the support plate. The shock absorber 3 is a fluid buffer filled with nitrogen gas. The outer circumference of the shock absorber 3 is provided with threads. It is connected with the controller bracket by thread. The motor controller 2 is fixedly connec...

Embodiment 2

[0029] Such as Figure 5 As shown, the shock absorber 3 is a fluid buffer filled with hydraulic oil, and there are four shock absorbers 3 distributed on the four corners of the bottom surface of the tray 5. The buffer member 7 is a V-shaped spring piece, and the two ends of the spring piece They are respectively abutted against the side of the controller liner 6 and the side blocking wall 8 . All the other are with embodiment 1.

Embodiment 3

[0031] Such as Figure 6 , Figure 7 As shown, the shock absorbers are four rubber shock absorbers. The top and bottom ends of the rubber shock absorbers are each provided with a connecting column 15 with an external thread, and the connecting column 15 on the top of the rubber shock absorber is threaded with the controller bracket 10. Connect, the motor controller 2 is then threaded on the connecting column 15 at the top of the rubber shock absorber. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com