Apron board of honeycomb sandwich structure and preparation method of apron board

A technology of honeycomb sandwich structure and skirt plate, which is applied in the fields of railway car body parts, railway car body, transportation and packaging, etc., which can solve the problems of high processing difficulty, complex shape and high cost, and achieve easy industrial production and processing technology Simple, Rigid-Enhancing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

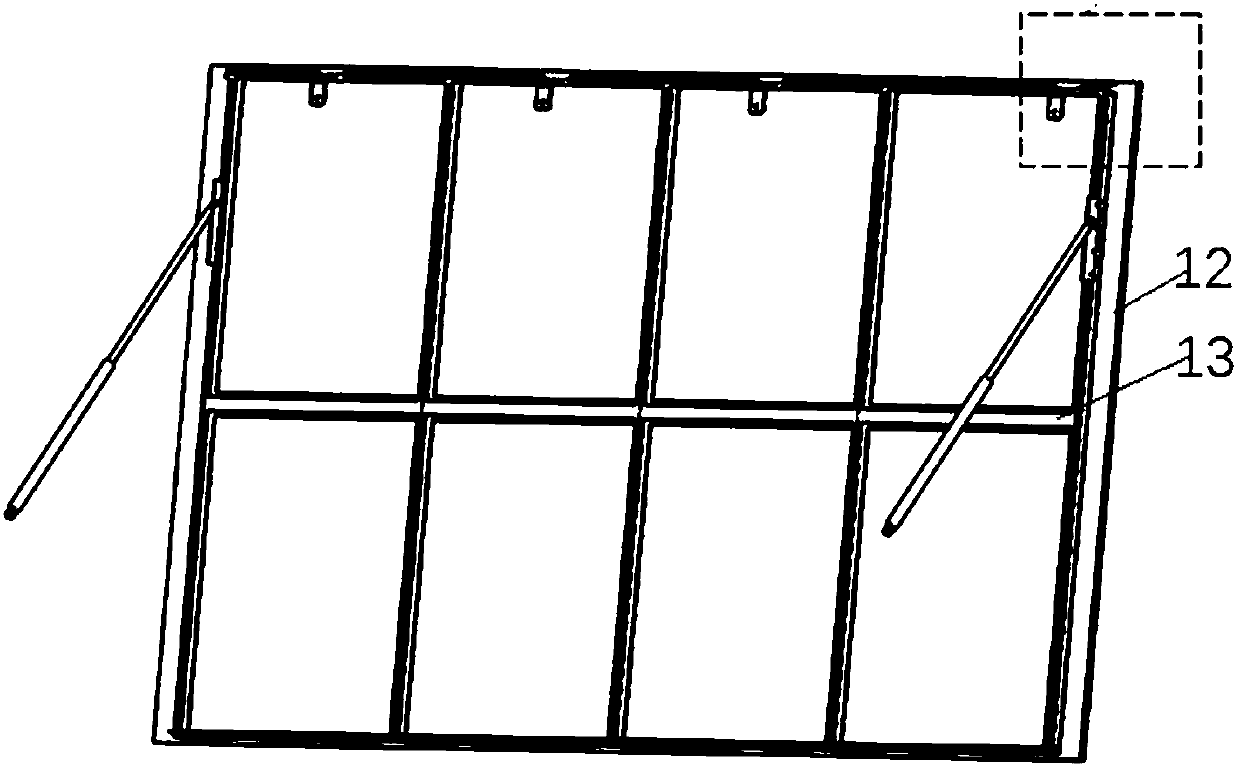

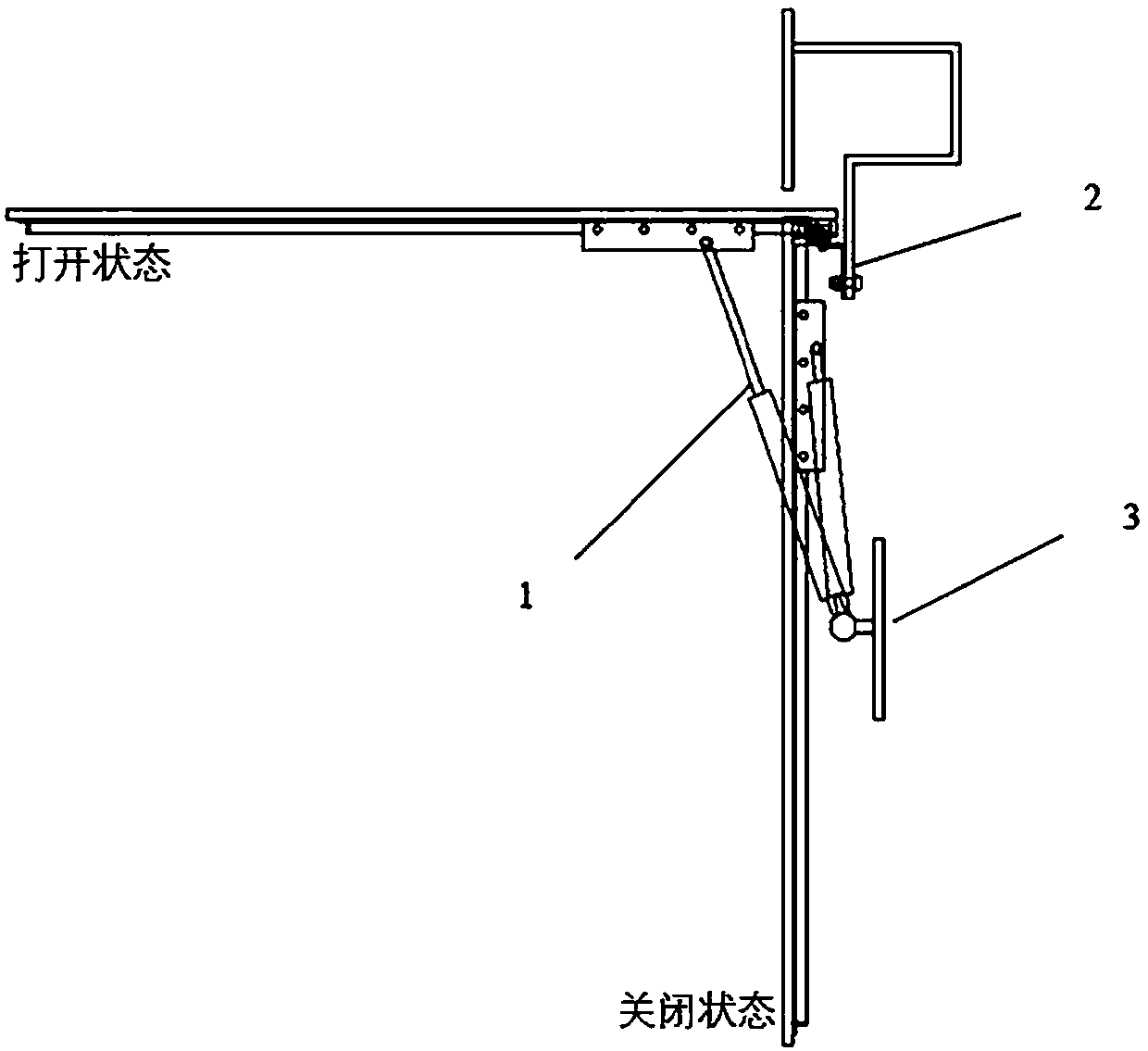

[0046] See attached Figure 1-7, the present embodiment provides a honeycomb sandwich structure apron, the apron includes a skeleton 13 and an apron main board 12, the apron main board 12 is a plate-like structure, and the skeleton 13 is integrally bonded to the apron main board 12 Fix to enhance the rigidity of the skirt board main body 12, and the skeleton 13 and the skirt board main board 12 are integrally fitted and fixed by bonding.

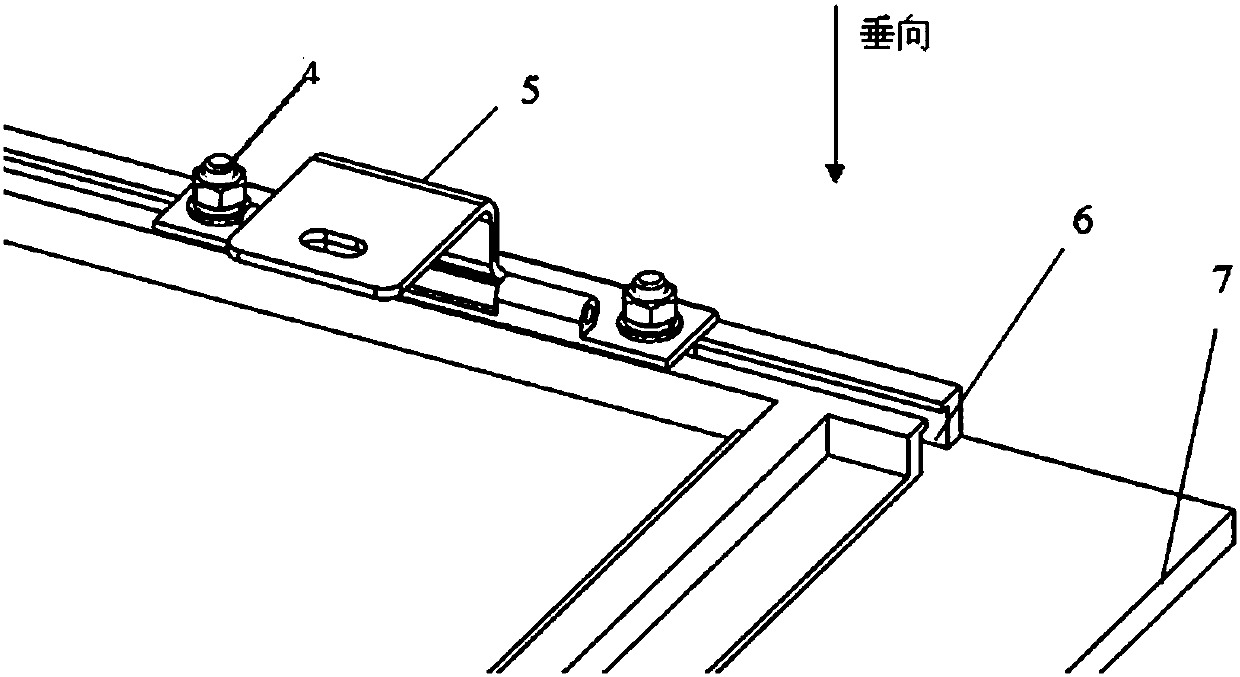

[0047] see image 3 , the top of the skeleton 13 is provided with a U-shaped chute 6, and a hinge 5 is arranged in the U-shaped chute 6. The installation position can be adjusted by sliding. After reaching the installation position, the hinge 5 is fixed with the U-shaped chute 6 by the bolt 4 . In this embodiment, the fixing device adopts the bolt 4, and the hinge 5 is connected with the U-shaped chute 6 through the bolt 4. The movement of the hinge 5 in the chute can be realized by loosening the bolt 4, moving to an appropriate position, ...

Embodiment 2

[0053] This embodiment provides a method for preparing a honeycomb sandwich structure skirt in Embodiment 1, the process flow is as follows Figure 8 As shown, the details are as follows:

[0054] S1. Mold opening: CNC machining skeleton-mainboard assembly mold, the assembly mold is as follows Image 6 As shown, the profile is extruded and welded into a skeleton, the hinge is formed by stamping, a U-shaped chute is opened on the top of the skeleton, and multiple mounting holes are opened on the top and both sides of the skeleton;

[0055] S2. Skin molding: Lay 8 layers of flame-retardant glass fiber-phenolic prepreg on the flat mold (gram weight 350g / m 2 , resin content 47%), and then covered with fluorine tetracloth, vacuum compaction; remove the vacuum bag, and then re-spread 3 layers of flame-retardant glass fiber-phenolic prepreg (gram weight 350g / m 2 , resin content 42%), vacuum compaction; push the flat mold into the autoclave, close the tank door, pressurize to 0.21MP...

Embodiment 3

[0060] This embodiment provides a method for preparing a honeycomb sandwich structure skirt in Embodiment 1, the process flow is as follows Figure 8 As shown, the details are as follows:

[0061] S1. Mold opening: CNC machining skeleton-mainboard assembly mold, the assembly mold is as follows Image 6 As shown, the profile is extruded and welded into a skeleton, the hinge is formed by stamping, a U-shaped chute is opened on the top of the skeleton, and multiple mounting holes are opened on the top and both sides of the skeleton;

[0062] S2. Skin molding: Lay 9 layers of flame-retardant glass fiber-phenolic prepreg (gram weight 400g / m2, resin content 47%) on the flat mold, then pave fluorine tetracloth, vacuum compact; remove the vacuum bag, and then re-spread 4 layers of flame-retardant glass fiber-phenolic prepreg (gram weight 400g / m 2 , resin content 45%), vacuum compaction; push the flat mold into the autoclave, close the tank door, pressurize to 0.23MPa, keep it at 130...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com