Caustic soda flake machine drum for solid caustic soda producing system

A production system and technology of caustic soda machine, applied in inorganic chemistry, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of serious corrosion, waste of resources, waste of spray water, etc., to improve corrosion resistance performance, improved service life, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

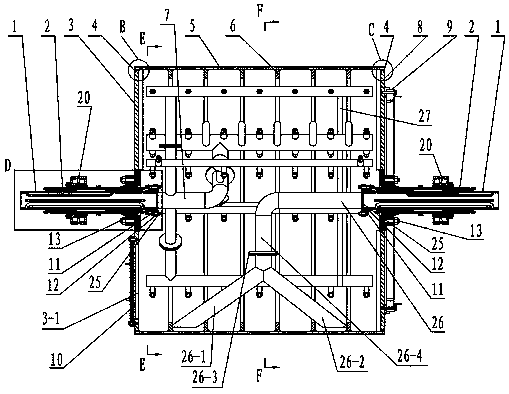

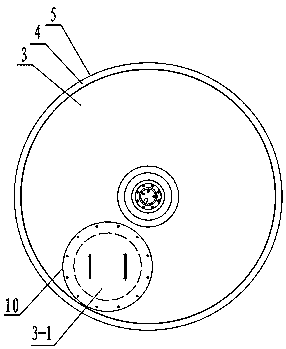

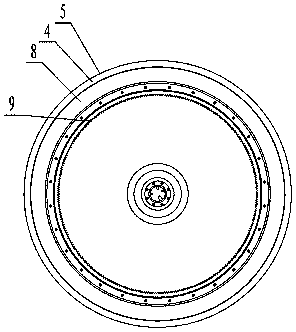

[0057] Such as figure 1 , figure 2 , image 3 , Figure 6 , Figure 7 , Figure 9 and Figure 10 As shown, the present invention includes a cylindrical shell 5, and the cylindrical shell 5 is rolled and welded by a nickel-based alloy N02201 plate, and there is only one longitudinal weld. In order to prevent the expansion of the cylindrical shell 5, avoid the cylindrical shell The body 5 produces cracks, and at least 6 annular support rings 6 are welded on the inner surface of the cylindrical shell 5, and a left flat cover 3 is welded on the left end of the cylindrical shell 5, and a manhole 3 is processed on the left flat cover 3 -1, and a manhole cover 10 is installed, a right flat cover 8 is welded at the right end of the cylindrical shell 5, and a gear 9 is installed on the right flat cover 8, and a left flat cover concave is processed on the outer edge of the left flat cover 3 Shape ring groove 3-2, is processed with right flat cover concave ring groove 8-1 at the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com