A kind of permeable concrete reinforcing agent and preparation method thereof

A technology of permeable concrete and reinforcing agent is applied in the field of concrete admixtures, which can solve the problems of substandard water permeability and insufficient strength, achieve significant economic and environmental benefits, save cement consumption, and widen application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

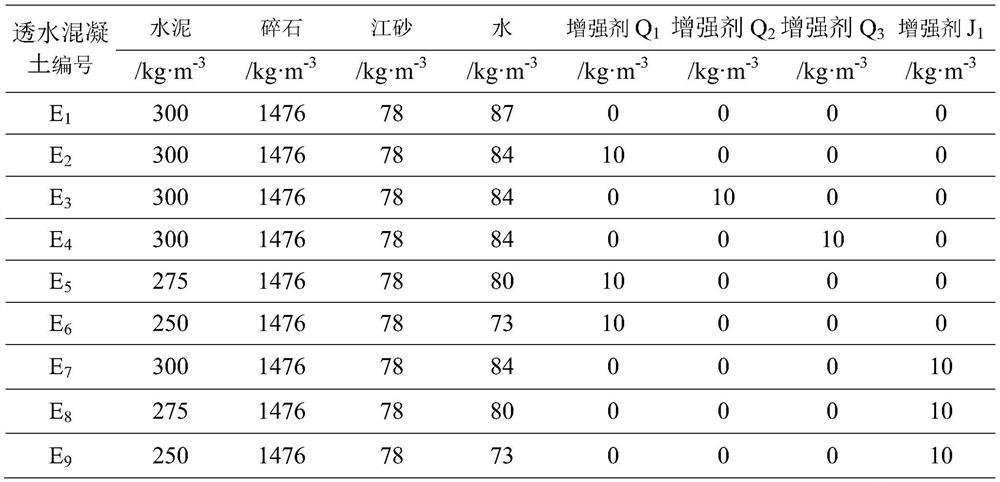

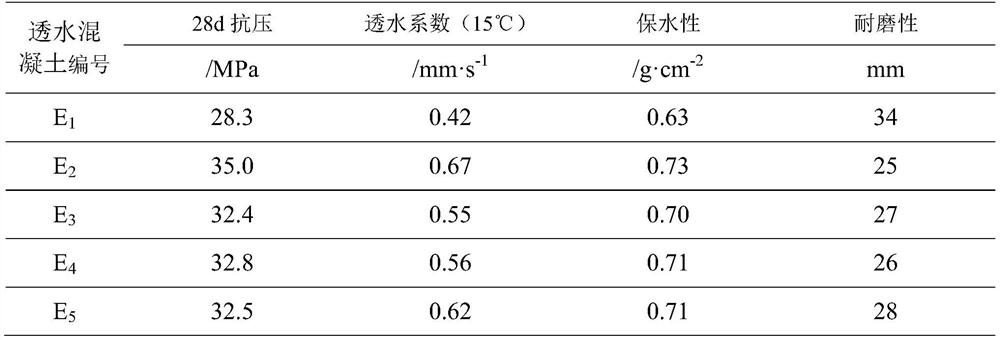

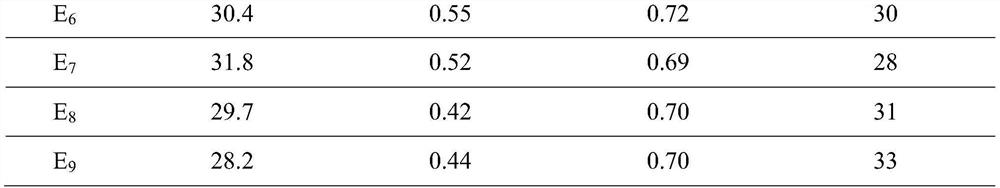

Embodiment 1

[0023] A permeable concrete reinforcing agent, the components and their parts by weight are: 11 parts of sodium nitrite, 7 parts of polycarboxylate superplasticizer, 65 parts of silica fume, 14 parts of calcium sulfate whiskers, triisopropyl 1 part of alcohol amine, 2 parts of methyl cellulose. The preparation method comprises the following steps: 1) weighing sodium nitrite, polycarboxylate superplasticizer, silica fume, calcium sulfate whiskers, alcohol amine compounds and cellulose water-retaining material according to the ratio; 2) weighing each raw material Put it into a mixer, and mix concrete at a speed of 400-500r / min for 45-60min at a temperature of 40-45°C to obtain a mixture; 3) Grind the obtained mixture until the particle size is less than 1um and accounts for 95 % or more, the permeable concrete reinforcing agent (strengthening agent Q 1 ).

Embodiment 2

[0025] A permeable concrete reinforcing agent, the components and their parts by weight are: 8 parts of sodium nitrite, 5 parts of polycarboxylate superplasticizer, 63.5 parts of silica fume, 18 parts of calcium sulfate whiskers, triisopropyl 2.5 parts of alcohol amine, 3 parts of methyl cellulose. The preparation method comprises the following steps: 1) weighing sodium nitrite, polycarboxylate superplasticizer, silica fume, calcium sulfate whiskers, alcohol amine compounds and cellulose water-retaining material according to the ratio; 2) weighing each raw material Put it into a mixer, and mix concrete at a speed of 400-500r / min for 45-60min at a temperature of 40-45°C to obtain a mixture; 3) Grind the obtained mixture until the particle size is less than 1um and accounts for 95 % or more, the permeable concrete reinforcing agent (strengthening agent Q 2 ).

Embodiment 3

[0027] A permeable concrete reinforcing agent, the components and their parts by weight are: 14 parts of sodium nitrite, 10 parts of polycarboxylate superplasticizer, 61 parts of silica fume, 12 parts of calcium sulfate whiskers, triisopropyl Alcohol amine 1.5 parts, methyl cellulose 1.5 parts. The preparation method comprises the following steps: 1) weighing sodium nitrite, polycarboxylate superplasticizer, silica fume, calcium sulfate whiskers, alcohol amine compounds and cellulose water-retaining material according to the ratio; 2) weighing each raw material Put it into a mixer, and mix concrete at a speed of 400-500r / min for 45-60min at a temperature of 40-45°C to obtain a mixture; 3) Grind the obtained mixture until the particle size is less than 1um and accounts for 95 % or more, the permeable concrete reinforcing agent (strengthening agent Q 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap