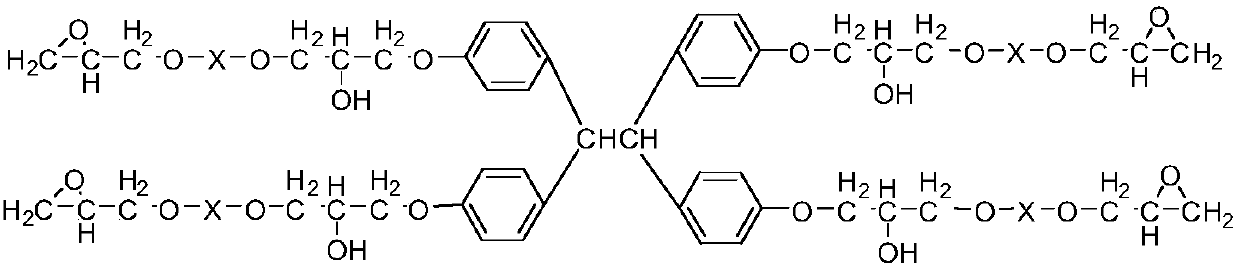

Tetrafunctional epoxy resin, and preparation method and application thereof

A technology of group epoxy resin and epoxy resin, applied in the field of tetrafunctional epoxy resin, can solve the problems of chemical leakage accident, difficult environmental management, and safety management, and achieves low equipment investment and low environmental management difficulty. , The effect of waste disposal is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

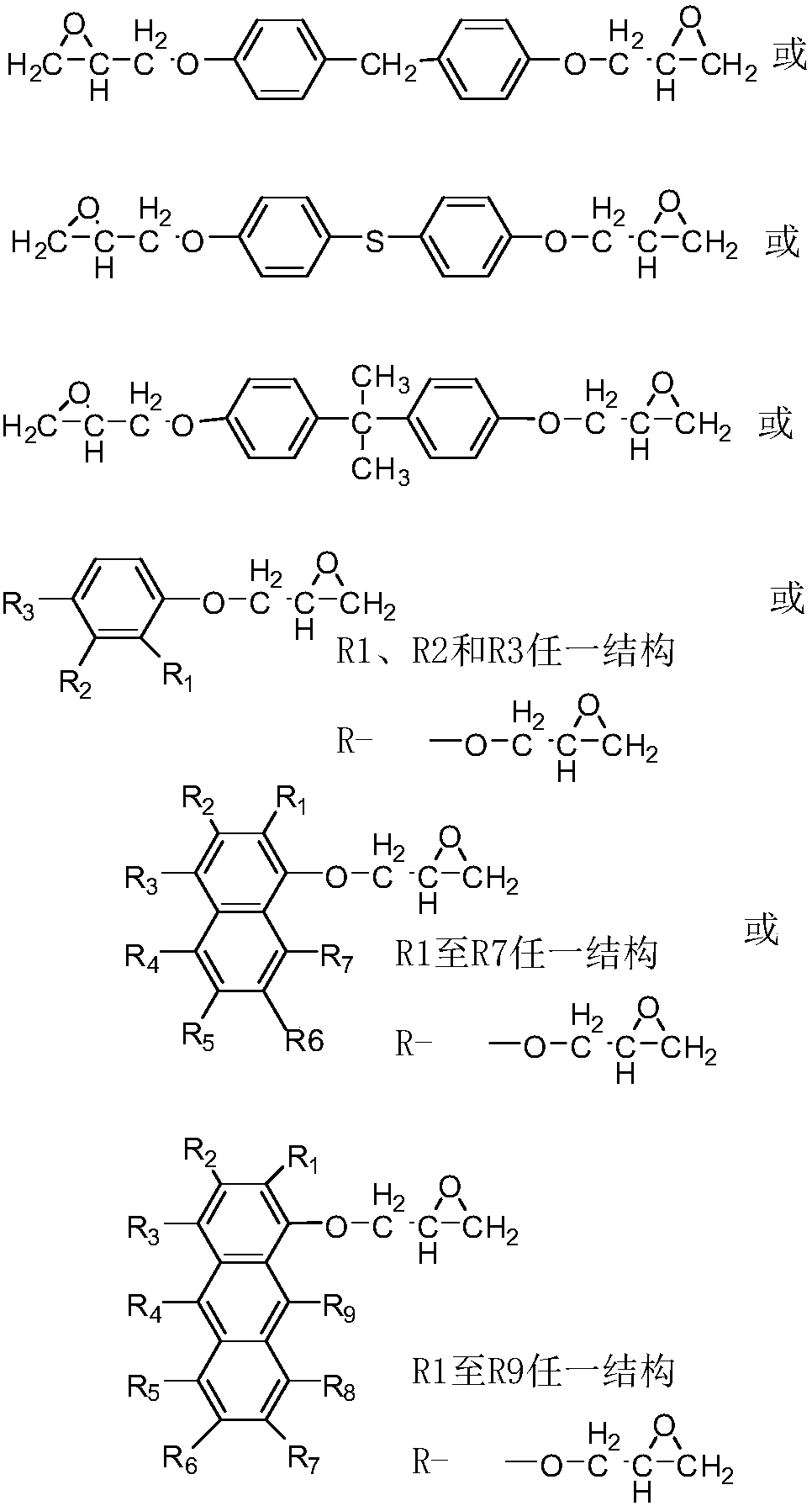

Method used

Image

Examples

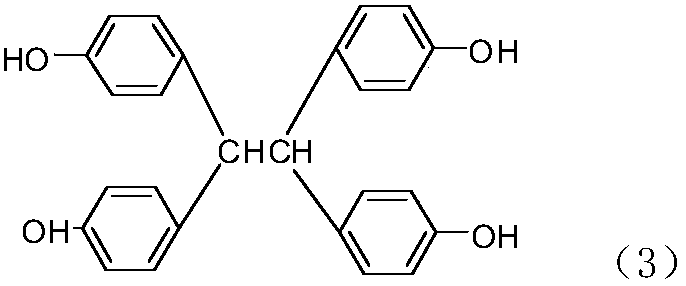

Embodiment 1

[0061] Add 315g bisphenol A type epoxy resin to the round bottom flask equipped with electric stirring, reflux condenser, and thermometer, pass nitrogen protection, turn on the heating device to heat bisphenol A type epoxy resin to 100°C, add 35 g tetraphenol Diethyl ethane and 0.18g triphenylphosphine were dissolved for 10 minutes and started to stir. Start the vacuum pump to evacuate the air in the four-necked round-bottomed flask, keep it below -0.095Mpa for 10 minutes, and then blow nitrogen to break the vacuum. Turn on the heating device to raise the temperature to about 130-140°C, control the exothermic temperature of the reaction at 150-155°C for 120 minutes, add 160g of acetone after the reaction, and dissolve it into a finished product to obtain resin 1. Epoxy equivalent 238g / Eq G Chromaticity 13.9 Hydrolyzed chlorine 238ppm Solid content 69.65%

Embodiment 2

[0063] Repeat embodiment 1, wherein the amount of bisphenol A epoxy resin is 245g, and the amount of tetraphenol ethane is 105g and all the other are the same as embodiment 1.

Embodiment 3

[0065] Repeat embodiment 1, wherein the amount of bisphenol A epoxy resin is 280g, and the amount of tetraphenol ethane is 70g and all the other are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com