A method for improving the water solubility of acetylisovaleryl tylosin tartrate

A technology of acetylisovaleryl tylosin tartrate and acetylisovaleryl tylosin, applied in chemical instruments and methods, organic chemistry, sugar derivatives, etc., can solve the inconvenience, acetylisovaleryl tylosin tartrate Can not be completely dissolved, affect the quality of the final product, etc., to achieve the effect of high yield, good water solubility and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

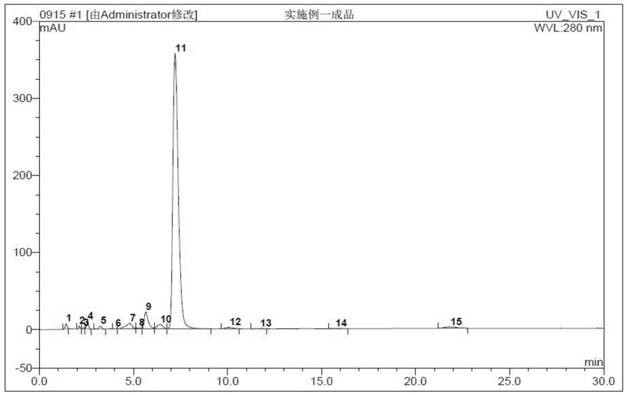

Embodiment 1

[0036] A method for improving the water solubility of acetylisovaleryl tylosin tartrate, the steps are as follows:

[0037] (1) Take 100g of the crude extract of acetylisovaleryl tylosin, add 200ml of purified water, fully stir and disperse with a magnetic stirrer, and control the temperature at 30°C. After washing, use suction filtration to separate the solid from the liquid and collect the solid ;

[0038] (2) Disperse the collected solids again with 200ml of purified water by magnetic stirring, while controlling the temperature at 30°C. After washing, separate the solids and liquids by suction filtration, and collect the washed acetylisovaleryl tylosin;

[0039] (3) Add a little purified water to the washed acetylisovaleryl tylosin, cool down to 10°C, gradually add food grade L-tartaric acid to adjust the pH to 3.0, liquid phase detection and control of acetylisovaleryl tylosin The concentration of mycocin is 200000ppm;

[0040] (4) Add polyaluminum chloride with a soluti...

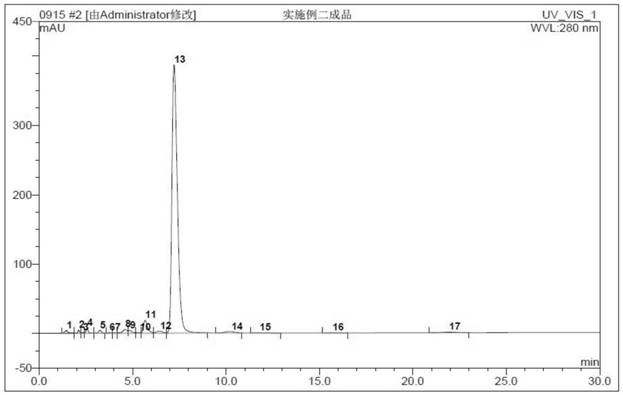

Embodiment 2

[0048] A method for improving the water solubility of acetylisovaleryl tylosin tartrate, the steps are as follows:

[0049] (1) Take 100g of the crude extract of acetylisovaleryl tylosin, add 350ml of purified water, fully stir and disperse with a magnetic stirrer, and control the temperature at 40°C. After washing, use suction filtration to separate the solid from the liquid, and collect the solid ;

[0050] (2) Magnetically stir and disperse the collected solids with 350ml of purified water again, while controlling the temperature at 40°C. After washing, separate the solids and liquids by suction filtration, and collect the washed acetylisovaleryl tylosin;

[0051] (3) Add a little purified water to the washed acetylisovaleryl tylosin, and cool down to 15°C, gradually add food grade L-tartaric acid to adjust the pH to 4.0, liquid phase detection and control of acetylisovaleryl tylosin The concentration of mycocin is 200000ppm;

[0052](4) Add polyaluminum chloride with a s...

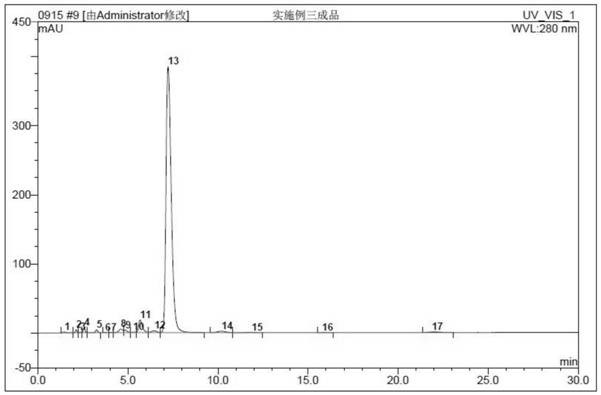

Embodiment 3

[0060] A method for improving the water solubility of acetylisovaleryl tylosin tartrate, the steps are as follows:

[0061] (1) Take 100g of the crude extract of acetylisovaleryl tylosin, add 500ml of purified water, fully stir and disperse with a magnetic stirrer, and control the temperature at 50°C. After washing, use suction filtration to separate the solid from the liquid, and collect the solid ;

[0062] (2) Magnetically stir and disperse the collected solids with 500ml of purified water again, while controlling the temperature at 50°C. After washing, separate the solids and liquids by suction filtration, and collect the washed acetylisovaleryl tylosin;

[0063] (3) Add a little purified water to the washed acetylisovaleryl tylosin, cool down to 20°C, gradually add food grade L-tartaric acid to adjust the pH to 5.0, liquid phase detection and control of acetylisovaleryl tylosin The concentration of mycocin is 200000ppm;

[0064] (4) Add polyaluminium chloride with a sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com