Extraction method and application of cantharis chitosan

An extraction method and a technology of cantharid shell, which are applied in the field of extracting chitosan from cantharid, can solve problems such as few reports, and achieve the effects of simple operation, reduced pollution and high degree of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

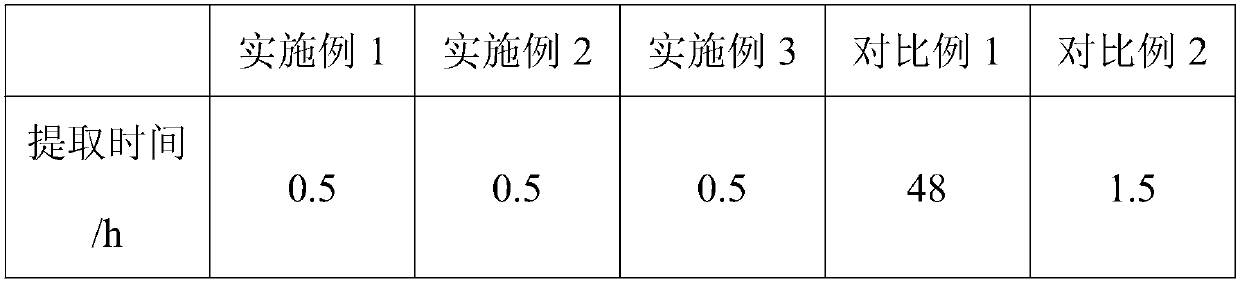

Examples

Embodiment 1

[0025] A method for extracting mylabris chitosan, comprising the following steps:

[0026] (1) collect mylabris, wash, and pulverize after drying and cross a 40-mesh sieve to get mylabris powder;

[0027] (2) add the anhydrous ether of 4 times amount to the mylabris powder of step (1) and degrease, dry, obtain the defatted mylabris powder;

[0028] (3) get the defatted cantharis powder that obtains in step (2), add EDTA solution, the mass volume ratio (g / mL) of defatted cantharis powder and EDTA solution is 1:25, and the concentration of EDTA solution is 18%, pH value 13, and then ultrasonicated for 25 minutes under the condition of power of 200W and frequency of 65kHz, filtered, washed the filter residue with water, and dried at 50°C to obtain chitin;

[0029] (4) Soak the chitin obtained in step (3) with 2 times the amount of sodium sulfite for 2.5 hours, remove the pigment, wash with water until neutral, and obtain decolorized chitin;

[0030] (5) Take decolorized chitin ...

Embodiment 2

[0032] A method for extracting mylabris chitosan, comprising the following steps:

[0033] (1) collect mylabris, wash, and pulverize after drying and cross a 35-mesh sieve to get mylabris powder;

[0034] (2) add 3 times the anhydrous ether of amount to the mylabris powder of step (1) and carry out degreasing, dry, obtain the degreasing mylabris powder;

[0035] (3) get the defatted cantharis powder that obtains in step (2), add EDTA solution, the mass volume ratio (g / mL) of defatted cantharis powder and EDTA solution is 1:20, and the concentration of EDTA solution is 17%, pH value 13, then ultrasonicated for 30 minutes under the condition of power of 150W and frequency of 50kHz, filtered, washed the filter residue with water, and dried at 40°C to obtain chitin;

[0036] (4) Soak the chitin obtained in step (3) with 1 times the amount of sodium sulfite for 2 hours, remove the pigment, wash with water until neutral, and obtain decolorized chitin;

[0037] (5) Take decolorized...

Embodiment 3

[0039] A method for extracting mylabris chitosan, comprising the following steps:

[0040] (1) collect mylabris, wash, and pulverize after drying and cross a 45-mesh sieve to get the mylabris powder;

[0041] (2) add the anhydrous ether of 5 times amount to the mylabris powder of step (1) and carry out degreasing, dry, obtain the degreasing mylabris powder;

[0042] (3) get the defatted cantharis powder that obtains in step (2), add EDTA solution, the mass volume ratio (g / mL) of defatted cantharis powder and EDTA solution is 1:30, and the concentration of EDTA solution is 19%, pH value 13, then ultrasonicated for 20 minutes under the condition of power of 250W and frequency of 80kHz, filtered, washed the filter residue with water, and dried at 60°C to obtain chitin;

[0043] (4) Soak the chitin obtained in step (3) with 3 times the amount of sodium sulfite for 3 hours, remove the pigment, wash with water until neutral, and obtain decolorized chitin;

[0044] (5) Take decolor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com