Blend containing PHBV and rice husks, and preparation method and use thereof

A blend, rice husk technology, applied in chemical instruments and methods, biological water/sewage treatment, special compound water treatment, etc., can solve the problem of no rice husk application, achieve excellent biodegradation performance, and improve technical practicability , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

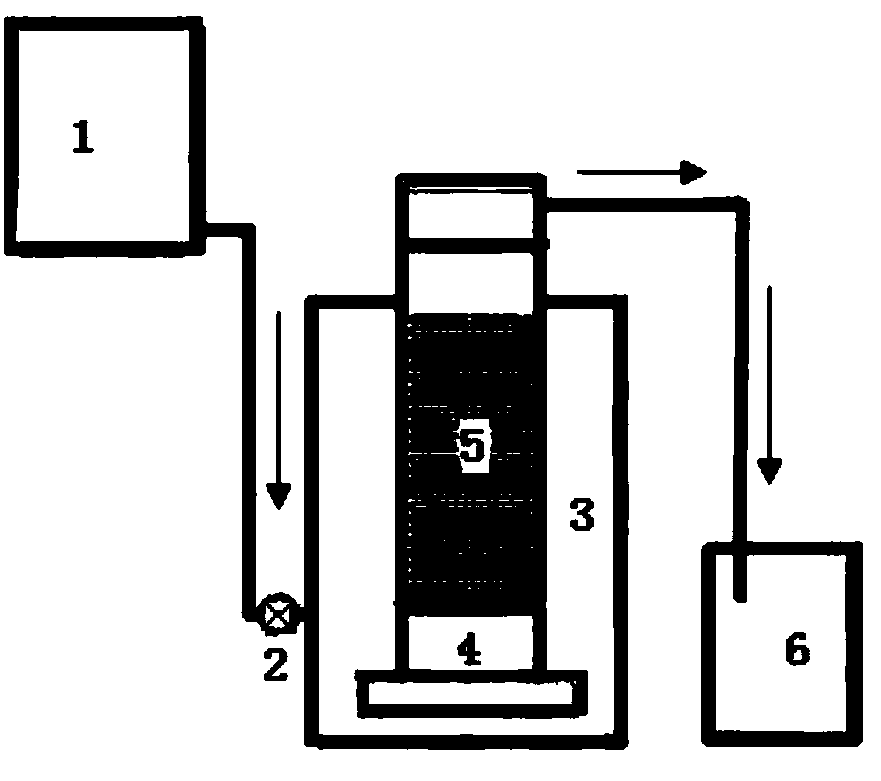

Method used

Image

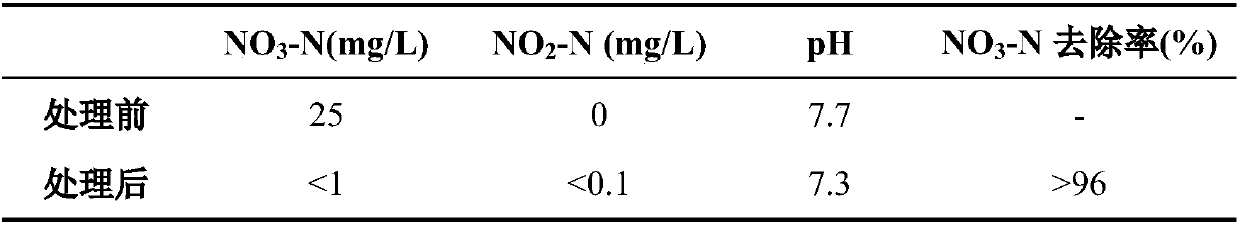

Examples

Embodiment 1

[0035] The preparation method of blend, comprises:

[0036] The PHBV (molecular weight 50000) of 32 weight parts, the rice husk (particle diameter 120 μm) of 35 weight parts, the water of 2 weight parts and the KH-550 of 1 weight part are put into the reactor and stirred; Extrude and granulate at 175°C in the extruder to obtain a blend.

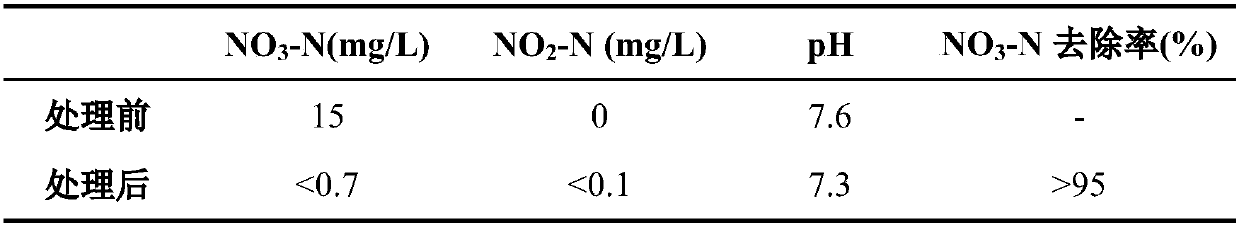

Embodiment 2

[0038] The preparation method of blend, comprises:

[0039] Put 45 parts by weight of PHBV (molecular weight 80000), 33 parts by weight of rice husk (150 μm in particle size), 5 parts by weight of water and 2 parts by weight of KH-560 into the reactor and stir evenly, then add to the twin-screw extruder Extrude and granulate at 172°C in the extruder to obtain a blend.

Embodiment 3

[0041] The preparation method of blend, comprises:

[0042] Put 40 parts by weight of PHBV (molecular weight 70000), 45 parts by weight of rice husk (150 μm in particle size), 2 parts by weight of water and 3 parts by weight of KH-570 into the reactor and stir evenly, then add to the twin-screw extruder Extrude and granulate at 175°C in the extruder to obtain a blend.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com