Manufacturing method and device of three-dimensional minute metal structural additive

A metal structure and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of insufficient mechanical properties, difficult control, large porosity, etc., and achieve the effects of low cost, high processing accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Example 1 Manufacture of three-dimensional fine metal structure additive

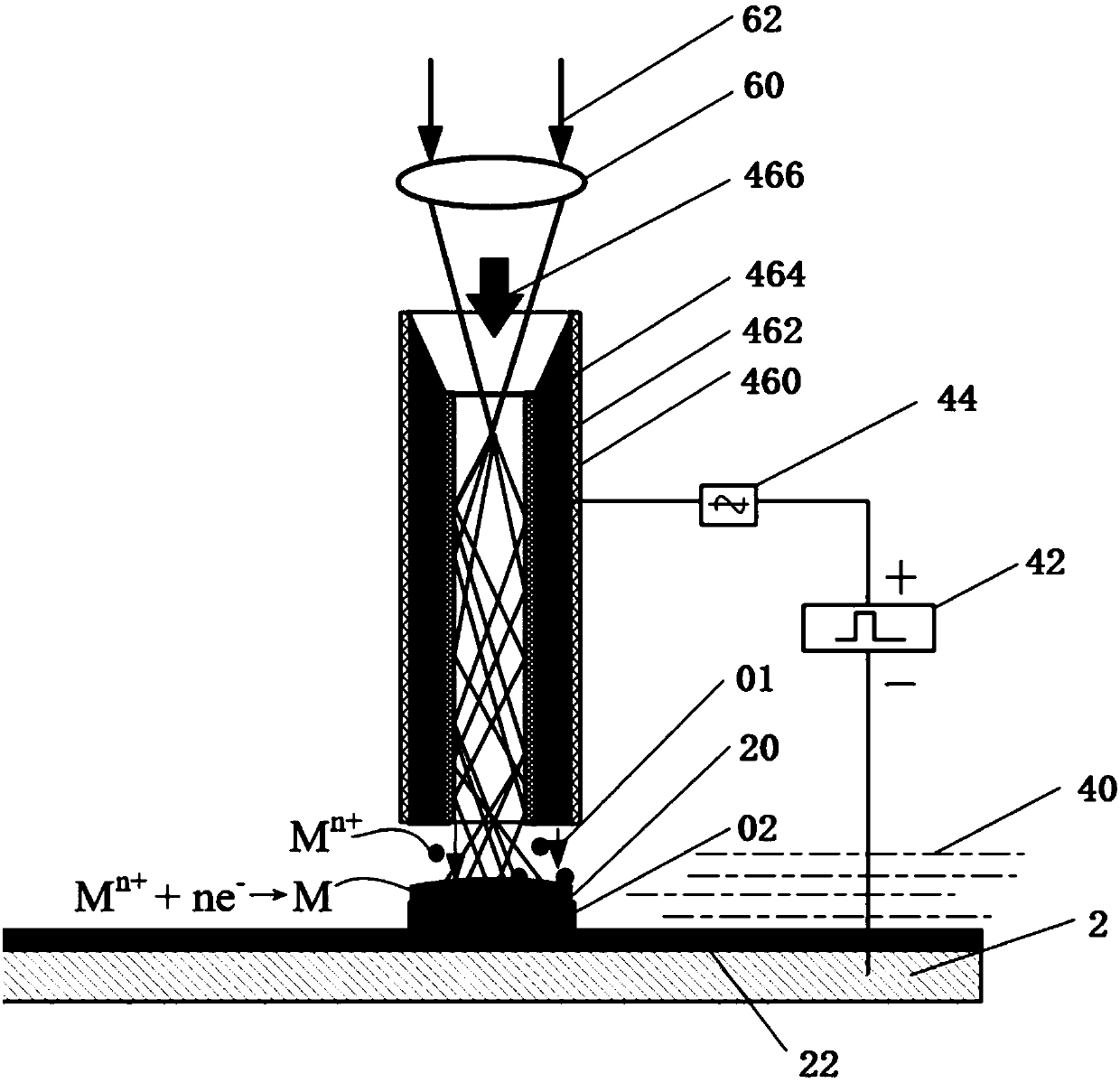

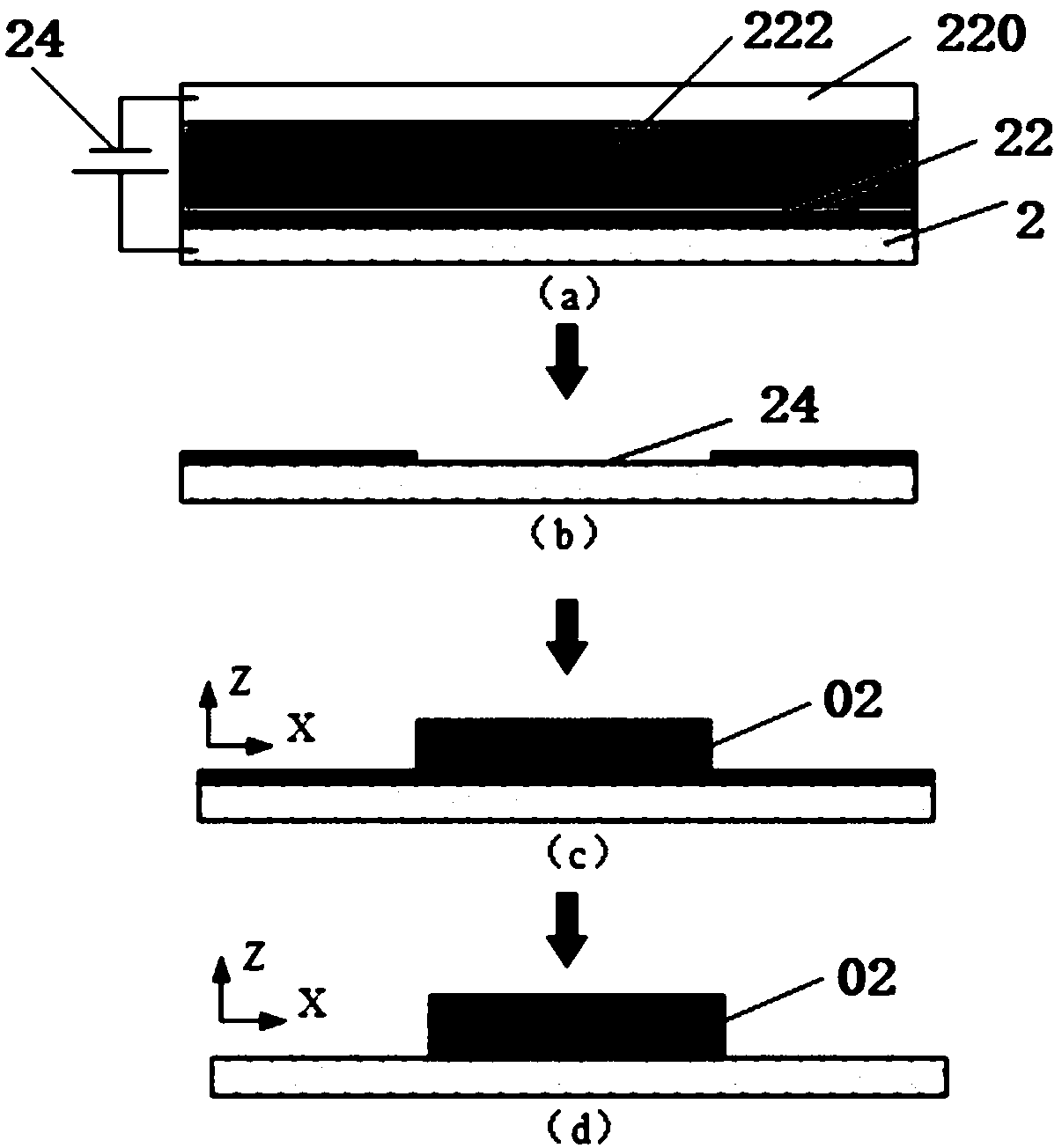

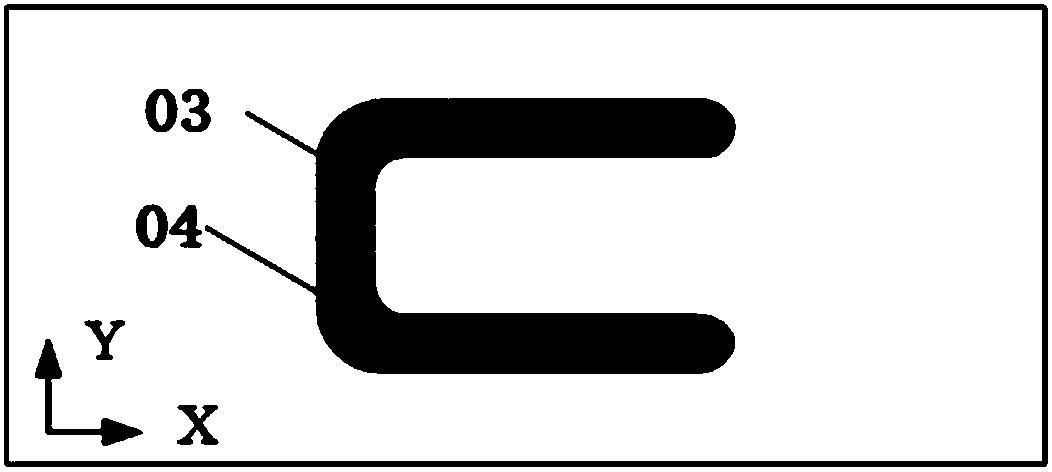

[0088] The schematic diagram of the manufacturing method of the three-dimensional fine metal structure additive in this embodiment is as follows figure 1 shown.

[0089] In this embodiment, the manufacturing method of three-dimensional fine metal structure additive includes:

[0090] (1) The laser beam 62 is focused by the focusing lens 60 and injected into the liquid core fiber 464 , and the laser beam 62 is transmitted to the surface electrodeposition area of the substrate 2 by using the internal total reflection of the liquid core fiber 464 / electroforming solution 40 interface.

[0091] Wherein, the liquid-core optical fiber 464 is installed in the metal conduit 462 . The side wall of the metal conduit 462 is insulated by electrostatic spraying, that is, the outer wall of the metal conduit 462 is coated with an insulating layer 460, which is beneficial to reduce the influence of stray cur...

Embodiment 2

[0097] Example 2 Manufacture of three-dimensional fine metal structure additive

[0098]In this embodiment, the side wall of the metal conduit 462 is insulated by chemical deposition (CVD); the thickness of the oxide layer / photoresist film is 0.1-10 μm; the liquid-core optical fiber and the metal capillary wrapping the liquid-core optical fiber A tool electrode is formed; the rest are the same as in Embodiment 1.

Embodiment 3

[0099] Example 3 Manufacture of three-dimensional fine metal structure additive

[0100] The laser energy used in this embodiment>10 4 W / cm 2 , to melt the deposited metal, to realize the melting and coagulation of metal materials, which is beneficial to reduce the porosity of the electrodeposited structure, thereby improving the compactness and mechanical properties of the electrodeposited microstructure; the thickness of the oxide layer / photoresist film Be 10 μm; All the other are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com