Anchor cable supporting system with impact resistance

An anchor cable support and impact resistance technology, which is used in the installation of anchor rods, mining equipment, earthwork drilling, etc., can solve the problems of lack of anti-fall protection function and insufficient support of anchor cable support structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

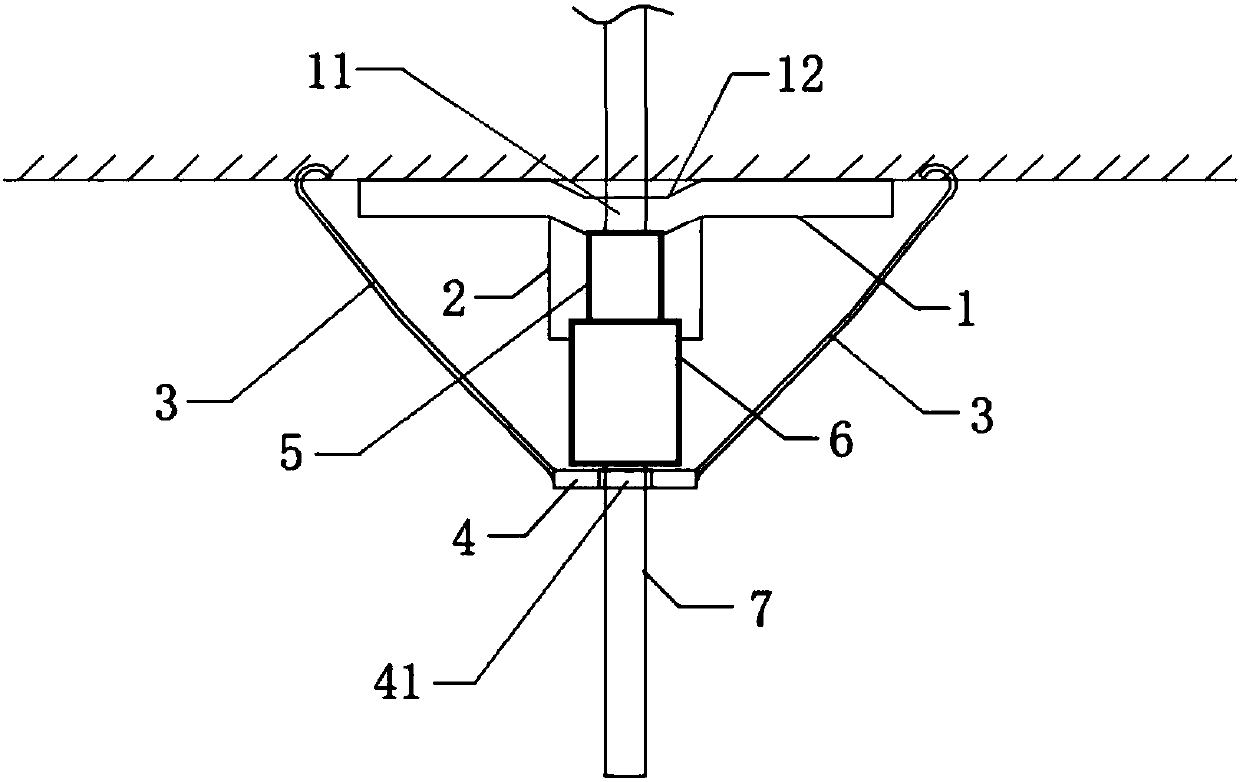

[0021] An anchor cable support system with impact resistance, comprising pressure relief tray 1, pressure pipe protective cover 2, anti-drop hook 3, anti-fall ring 4, pressure pipe 5, lock 6, anchor cable 7, the The pressure relief tray 1 is rectangular, and the central position of the pressure relief tray 1 has a recessed part 12, and the center position of the recessed part 12 has a first anchor cable hole 11, and the lower end of the recessed part 12 is fixedly connected with a pressure relief pipe protection Cover 2, the pressure-releasing tube protective cover 2 is cylindrical, the pressure-releasing tube 5 is sleeved in the pressure-releasing tube protective cover 2, and the lower end of the pressure-relieving tube 5 is connected with a The lockset 6 with limiting effect, the anti-fall ring 4 is located below the lockset 6, the center of the anti-fall ring 4 has a second anchor cable hole 41, one end of the anti-fall hook 3 is a hook body, and the other end is a hanging r...

Embodiment 2

[0029] An anchor cable support system with impact resistance, comprising pressure relief tray 1, pressure pipe protective cover 2, anti-drop hook 3, anti-fall ring 4, pressure pipe 5, lock 6, anchor cable 7, the The pressure relief tray 1 is rectangular, and the central position of the pressure relief tray 1 has a recessed part 12, and the central position of the recessed part 12 has a first anchor cable hole 11, and the lower end of the recessed part 12 is fixedly connected with a pressure relief pipe protection Cover 2, the pressure-releasing tube protective cover 2 is cylindrical, the pressure-releasing tube 5 is sleeved in the pressure-releasing tube protective cover 2, and the lower end of the pressure-relieving tube 5 is connected with a The lockset 6 with limiting effect, the anti-fall ring 4 is located below the lockset 6, the center of the anti-fall ring 4 has a second anchor cable hole 41, one end of the anti-fall hook 3 is a hook body, and the other end is a hanging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength value | aaaaa | aaaaa |

| Tensile strength value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com