A method for evaluating the internal quality stability of popping beads for cigarettes

A technology of quality stability and evaluation method, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of difficulty in effectively monitoring the internal quality changes of cigarette explosive beads, complex components of cigarette explosive beads, etc., to improve quality and safety control. Level, intuitive, avoid the effect of missing information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1. Materials

[0055] 1.1 Materials, reagents and instruments

[0056] The samples of honey-sweet, light-sweet and mint-flavored popping beads produced by Guangzhou Xingye Biotechnology Co., Ltd. are numbered A-C respectively.

[0057] n-Hexane is chromatographically pure.

[0058] 7890B-5977A Gas Chromatography Mass Spectrometry Instrument (Agilent, USA); HP-5MS Capillary Column (Specification: 30m×0.32mm×0.25μm, Agilent, USA); KQ-700DB CNC Ultrasonic Extractor (Kunshan Ultrasonic Instrument Co., Ltd. ); HY-8 oscillator (Changzhou Guohua Electric Co., Ltd.). 0.45 μm organic phase needle filter membrane (Jin Teng Company).

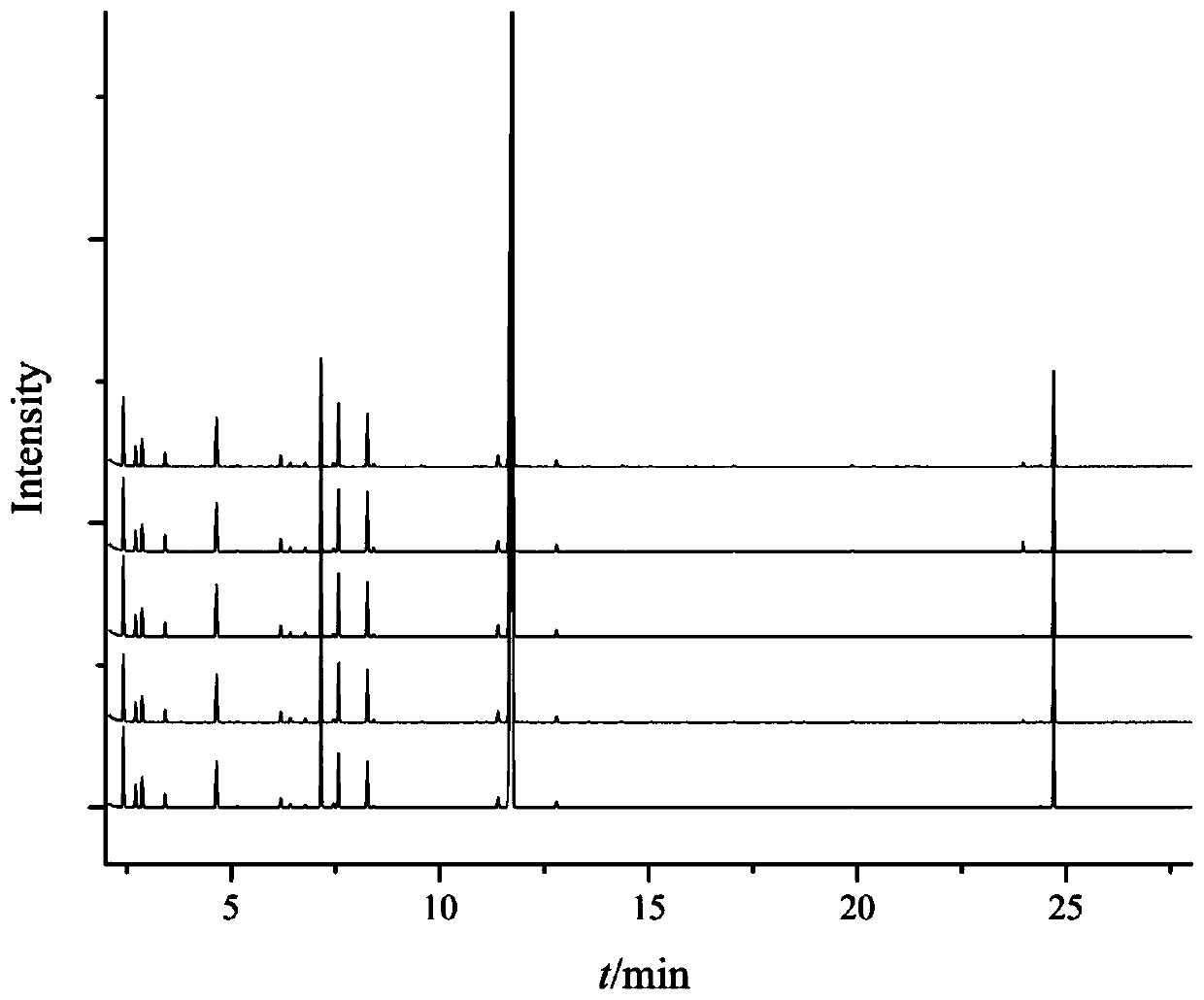

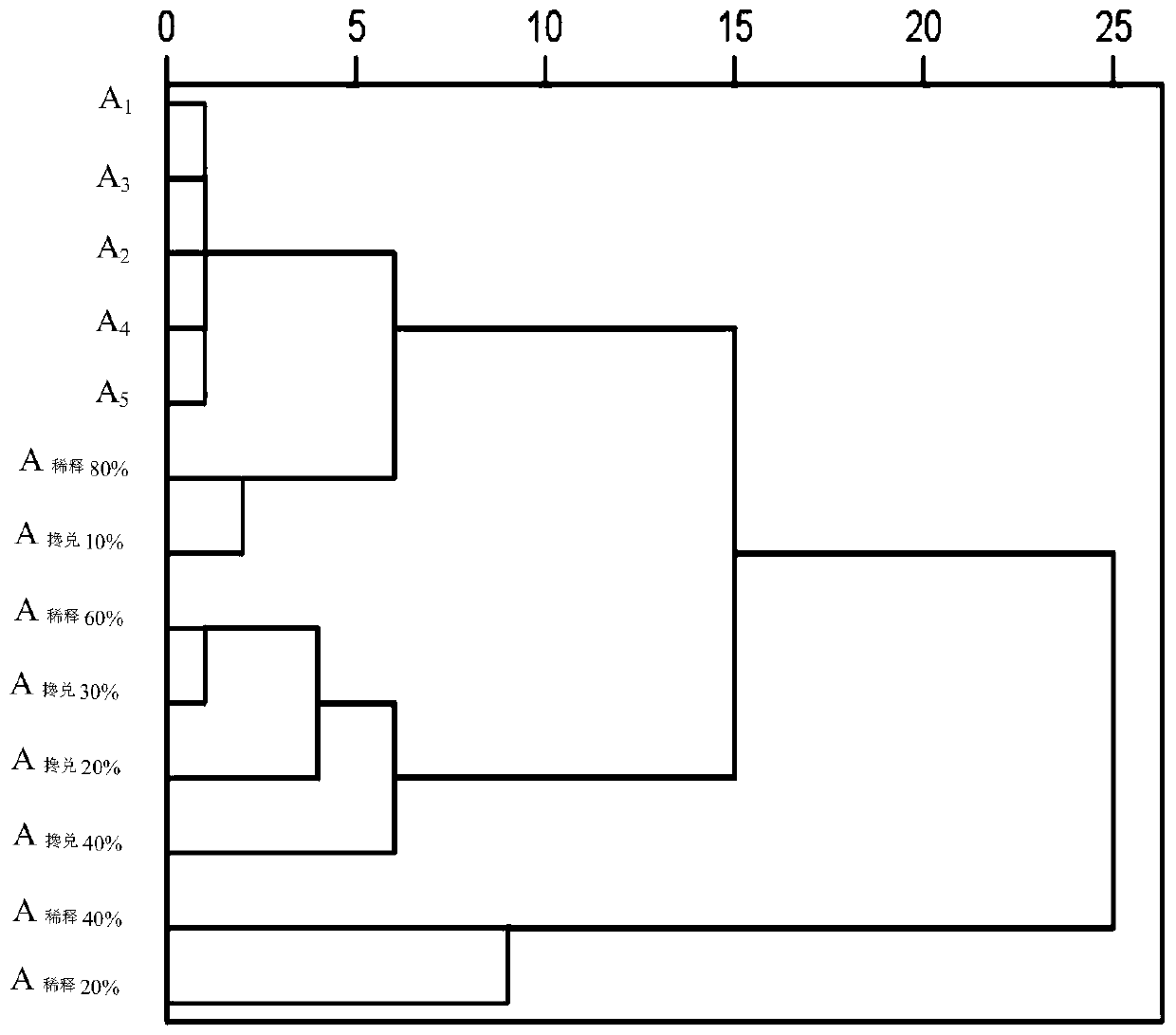

[0059] 2. Method

[0060] 2.1 Processing of samples

[0061] Grind the popcorn sample with a mortar, and take the contents of the popcorn and pass through a 0.45 μm organic phase needle filter membrane for later use. Use a pipette gun to accurately pipette 0.5mL of the content of the popping beads into a 50mL conical flask with a stopper, add ...

Embodiment 2

[0088] 1. Materials, reagents and instruments are the same as in Example 1.

[0089] 2.1 Processing of samples

[0090] Grind the popcorn sample with a mortar, and filter the contents of the popcorn through a 0.22 μm organic needle filter membrane for later use. Use a pipette gun to accurately pipette 0.3mL of the contents of the popping beads into a 50mL Erlenmeyer flask with a stopper, add 3.0mL of n-hexane solution containing n-heptadecane, shake and extract for 20min, after standing still, take the supernatant and filter it through the organic phase After the membrane passes through the membrane, it is analyzed by gas chromatography-mass spectrometry. The concentration of the n-hexane solution containing n-heptadecane is 0.12 mg / mL, so the ratio of the content of the popping beads to the internal standard in the internal standard solution is 1 mL: 1.2 mg.

[0091] 2.2 Gas chromatography-mass spectrometry analysis

[0092] The analysis conditions are: chromatographic col...

Embodiment 3

[0097] 1. Materials, reagents and instruments are the same as in Example 1.

[0098] 2.1 Processing of samples

[0099] Grind the popcorn sample with a mortar, and filter the contents of the popcorn through a 0.22 μm organic needle filter membrane for later use. Use a pipette gun to accurately pipette 1.0mL of the contents of the popping beads into a 50mL Erlenmeyer flask with a stopper, add 10.0mL of n-hexane solution containing n-heptadecane, shake and extract for 60min, after standing still, take the supernatant and filter it through the organic phase After passing through the membrane, it was analyzed by gas chromatography-mass spectrometry. The concentration of the n-hexane solution containing n-heptadecane is 0.2mg / mL, so the ratio of the content of the popping beads and the internal standard in the internal standard solution is 1mL: 2mg.

[0100] 2.2 Analysis by gas chromatography mass spectrometry

[0101] The analysis conditions are: chromatographic column: Agilent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com