Polishing liquid, polishing liquid set, and substrate polishing method

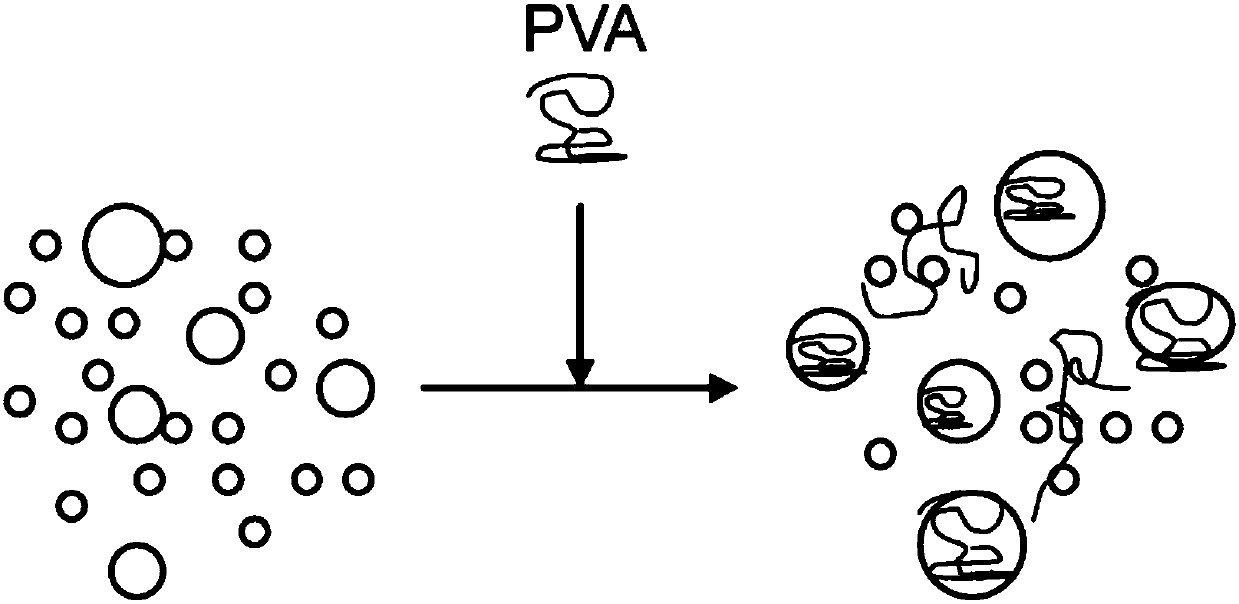

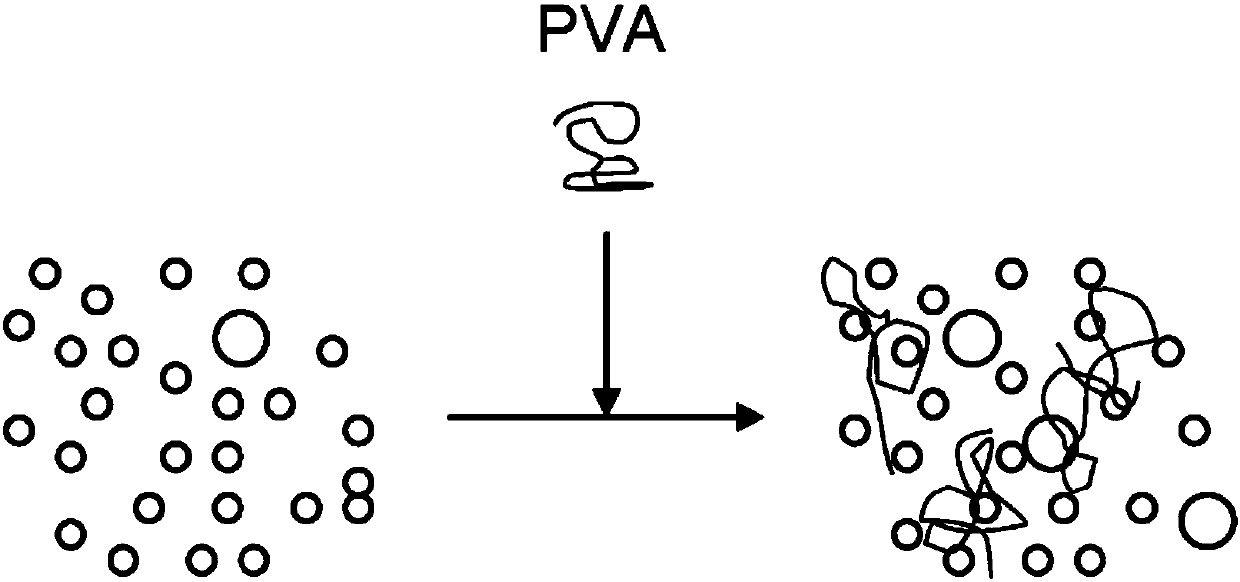

一种研磨方法、研磨液的技术,应用在研磨液领域,能够解决研磨损伤等问题,达到低研磨损伤、提高研磨选择性、抑制研磨速度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

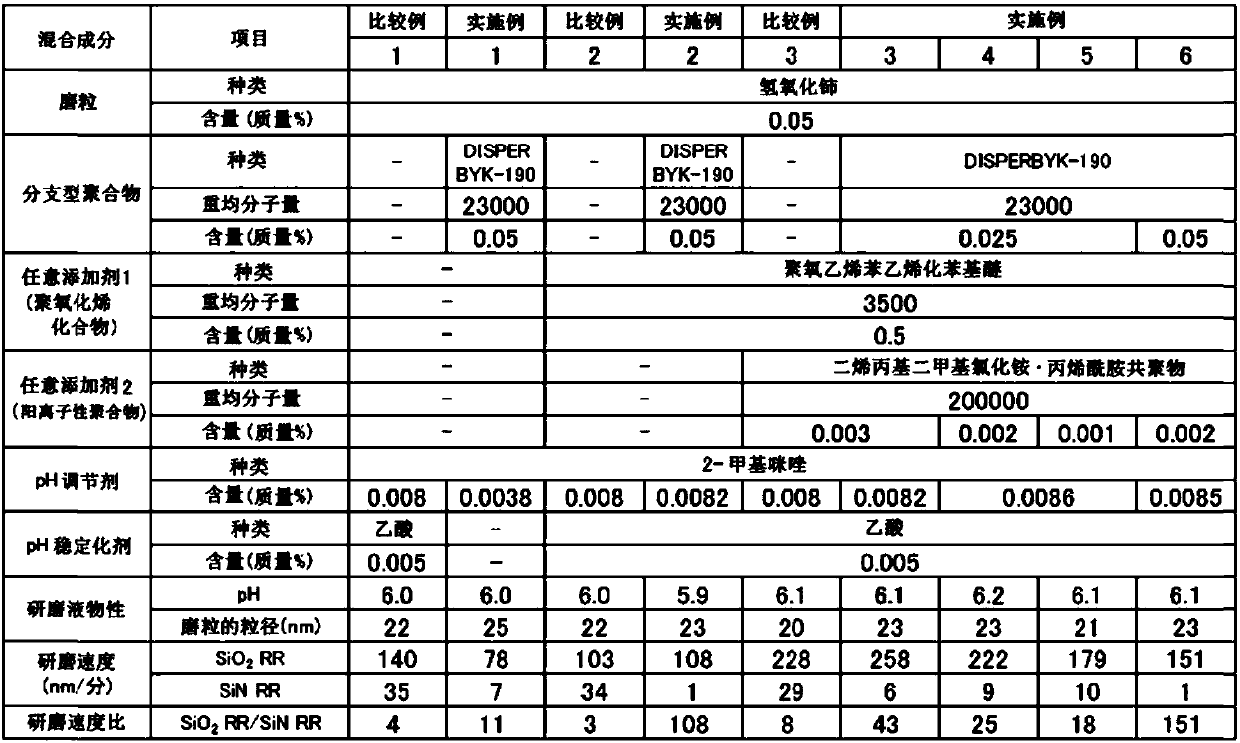

[0239] By mixing 100 g of the storage solution for the additive liquid, 850 g of water, and 50 g of the storage solution for the cerium hydroxide suspension, a pH 6.0 containing 0.05% by mass of cerium hydroxide-containing abrasive grains and 0.05% by mass of the branched polymer was prepared. The polishing solution for CMP in which the storage solution for the additive solution contains a branched polymer [manufactured by BYK-Chemie GmbH, trade name: DISPERBYK-190, non-volatile content: 40% by mass, acid value: 10 mgKOH / g, weight-average molecular weight : 23000] 0.5% by mass, 0.038% by mass of 2-methylimidazole [pH adjuster], and 99.462% by mass of water.

Embodiment 2

[0241] By mixing 100 g of the storage solution for the additive liquid, 850 g of water, and 50 g of the storage solution for the cerium hydroxide suspension, an abrasive grain containing 0.05% by mass of cerium hydroxide, 0.05% by mass of a branched polymer, 0.5% by mass of A polishing solution for CMP of pH 5.9 of polyoxyethylene styrenated phenyl ether, wherein the storage solution for the additive solution contains a branched polymer [manufactured by BYK-Chemie GmbH, trade name: DISPERBYK-190, non-volatile components: 40% by mass, acid value: 10 mgKOH / g, weight average molecular weight: 23000] 0.5% by mass, polyoxyethylene styrenated phenyl ether [manufactured by Kao Corporation, trade name: Emalgen A-500, weight average molecular weight: 3500] 5.0% by mass, 0.082% by mass of 2-methylimidazole [pH adjuster], 0.05% by mass of acetic acid [pH stabilizer], and 94.368% by mass of water.

Embodiment 3

[0243]By mixing 100 g of the storage solution for the additive liquid, 850 g of water, and 50 g of the storage solution for the cerium hydroxide suspension, an abrasive grain containing 0.05% by mass of cerium hydroxide, 0.025% by mass of a branched polymer, and 0.5% by mass of Polyoxyethylene styrenated phenyl ether, 0.003% by mass of diallyldimethylammonium chloride-acrylamide copolymer pH 6.1 polishing solution for CMP, wherein the storage solution for the additive solution contains branched Polymer [manufactured by BYK-Chemie GmbH, trade name: DISPERBYK-190, non-volatile content: 40% by mass, acid value: 10 mgKOH / g, weight average molecular weight: 23000] 0.25% by mass, polyoxyethylene styrenated phenyl ether [manufactured by Kao Corporation, trade name: Emalgen A-500, weight average molecular weight: 3500] 5.0% by mass, diallyldimethylammonium chloride acrylamide copolymer [cationic polymer, Nittobo Co., Ltd. Manufactured, trade name: PAS-J-81, weight average molecular we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com