Application of surface-modified silicon dioxide as abrasive particles

A silicon dioxide and surface modification technology, which is applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as insufficient control of the grinding rate of Si-containing materials, and achieve improved grinding selectivity, increased grinding rate, and improved Effect of Grinding Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

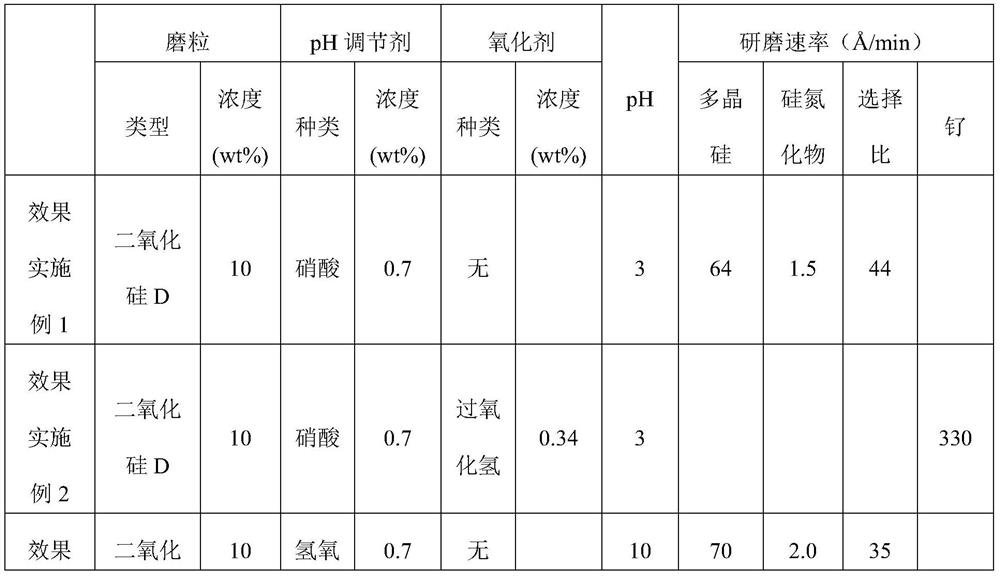

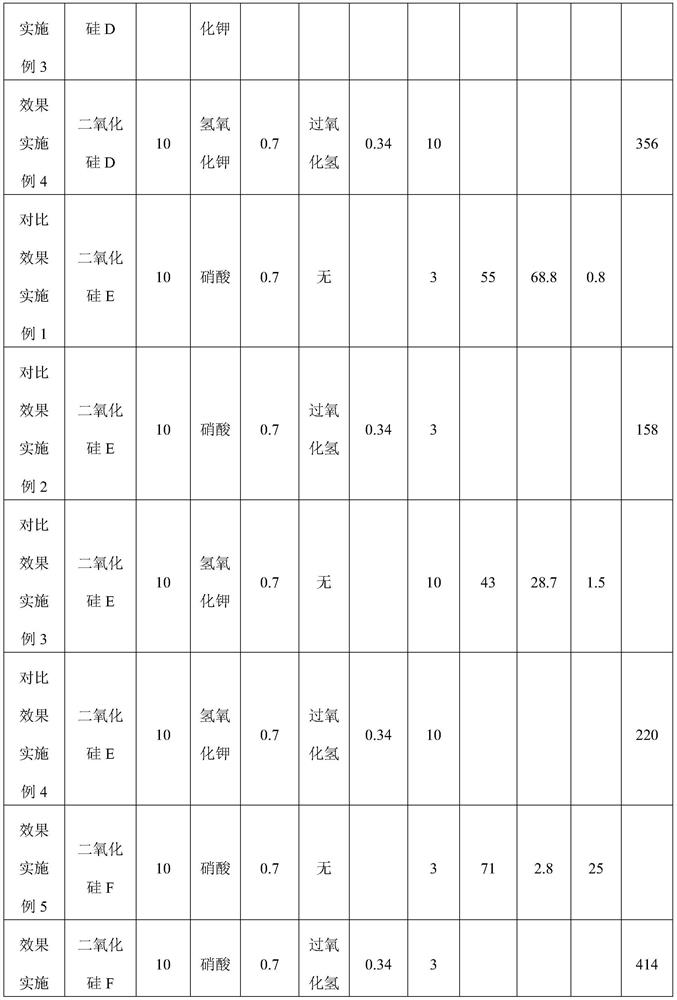

Examples

Embodiment 1 2

[0047] The synthesis of embodiment 1 silica D

[0048] Weigh 195g of colloidal silicon dioxide (average primary particle size is 35nm, average secondary particle size is 68nm), dissolve in a certain amount of water to form a colloidal silicon dioxide aqueous solution with a mass concentration of 19.5%. Separately, 0.63 mmol (0.73 g) of octaaminophenyl-POSS (CAS: 518359-82-5) was weighed and dissolved in 50 g of methanol.

[0049] The aqueous colloidal silica solution was added dropwise at a rate of 1 mL / min to the methanol solution of the above-mentioned silane coupling agent while stirring the aqueous colloidal silica solution at 25° C. under an air atmosphere at a stirring blade rotation speed of 600 rpm. After the dropwise addition, the pH was adjusted with KOH so that the pH of the solution was 8.0-9.0.

[0050] After adjusting the pH, the solution was left to stand in an air bath at 40°C for 8 hours, and then left to stand in an air bath at 60°C for 12 hours. Then, wate...

Embodiment 2 2

[0055] The synthesis of embodiment 2 silica F

[0056] Weigh 195g of colloidal silica (average primary particle diameter is 35nm, average secondary particle diameter is 68nm), dissolve in a certain amount of aqueous solution to form a colloidal silica aqueous solution with a mass concentration of 19.5%. Separately, 0.63 mmol (0.65 g) of octachloropropyl-POSS (CAS: 161678-38-2) was weighed and dissolved in 50 g of methanol.

[0057] The aqueous colloidal silica solution was added dropwise at a rate of 1 mL / min to the methanol solution of the above-mentioned silane coupling agent while stirring the aqueous colloidal silica solution at 25° C. under an air atmosphere at a stirring blade rotation speed of 600 rpm. After the dropwise addition, the pH is adjusted with a pH regulator (KOH) so that the pH of the solution is 8.0 to 9.0.

[0058] After adjusting the pH, the solution was left to stand in an air bath at 40°C for 8 hours, and then left to stand in an air bath at 60°C for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com