Polishing agent for silicon oxide, liquid additive, and method of polishing

A technology of abrasives and silicon oxide, applied in chemical instruments and methods, polishing compositions containing abrasives, grinding devices, etc., can solve problems such as excessive metal impurities and excess alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0105] The present invention is illustrated below through some examples, but the scope of the present invention is not limited to these examples.

[0106] (production of cerium oxide particles)

[0107] Put 2kg of cerium carbonate hydrate in a platinum container and calcinate in air at 800°C for 2 hours to obtain about 1kg of yellow-white powder. Phase identification of this powder by X-ray diffraction method confirmed that it was cerium oxide. The particle size of the calcined powder is 30-100 μm. When the surface of the calcined powder particles was observed with a scanning electron microscope, grain boundaries of cerium oxide were observed. The primary particle size of cerium oxide surrounding the grain boundaries was measured, and the volume distribution had a median value of 190 nm and a maximum value of 500 nm. After dry pulverization of 1 kg of cerium oxide powder using a jet mill, the pulverized particles were observed with a scanning electron microscope, and it was...

Synthetic example 1

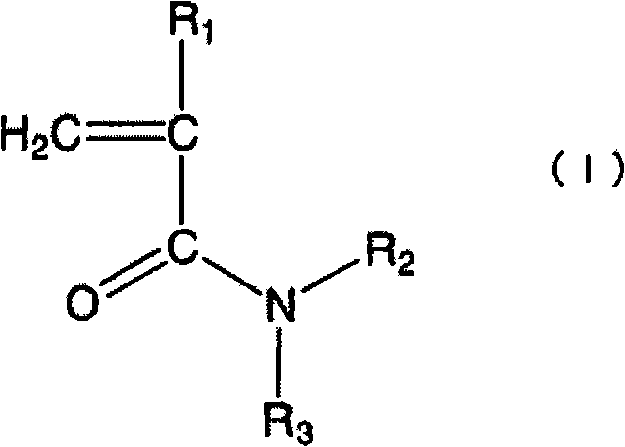

[0115] 280g of deionized water and 20g of 2-propanol were dropped into a 1-liter flask, and the temperature was raised to 90°C while stirring under a nitrogen atmosphere, and then 1g of a polymerization initiator (manufactured by Wako Pure Chemical Industry Co., Ltd., trade name V- 601) was dissolved in 100 g of acryloylmorpholine, and the resulting solution was poured into the flask over 2 hours. Thereafter, it was kept at 90° C. for 5 hours, then cooled and taken out to prepare a water-soluble polymer solution. The concentration of the water-soluble polymer in the solution was 25.3%.

Synthetic example 2

[0117] 50 g of N,N-diethylacrylamide and 50 g of acryloylmorpholine were synthesized by the method of Synthesis Example 1 to prepare a water-soluble polymer solution. The water-soluble polymer concentration in the solution was 25.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com