A fast chip removal polishing pad

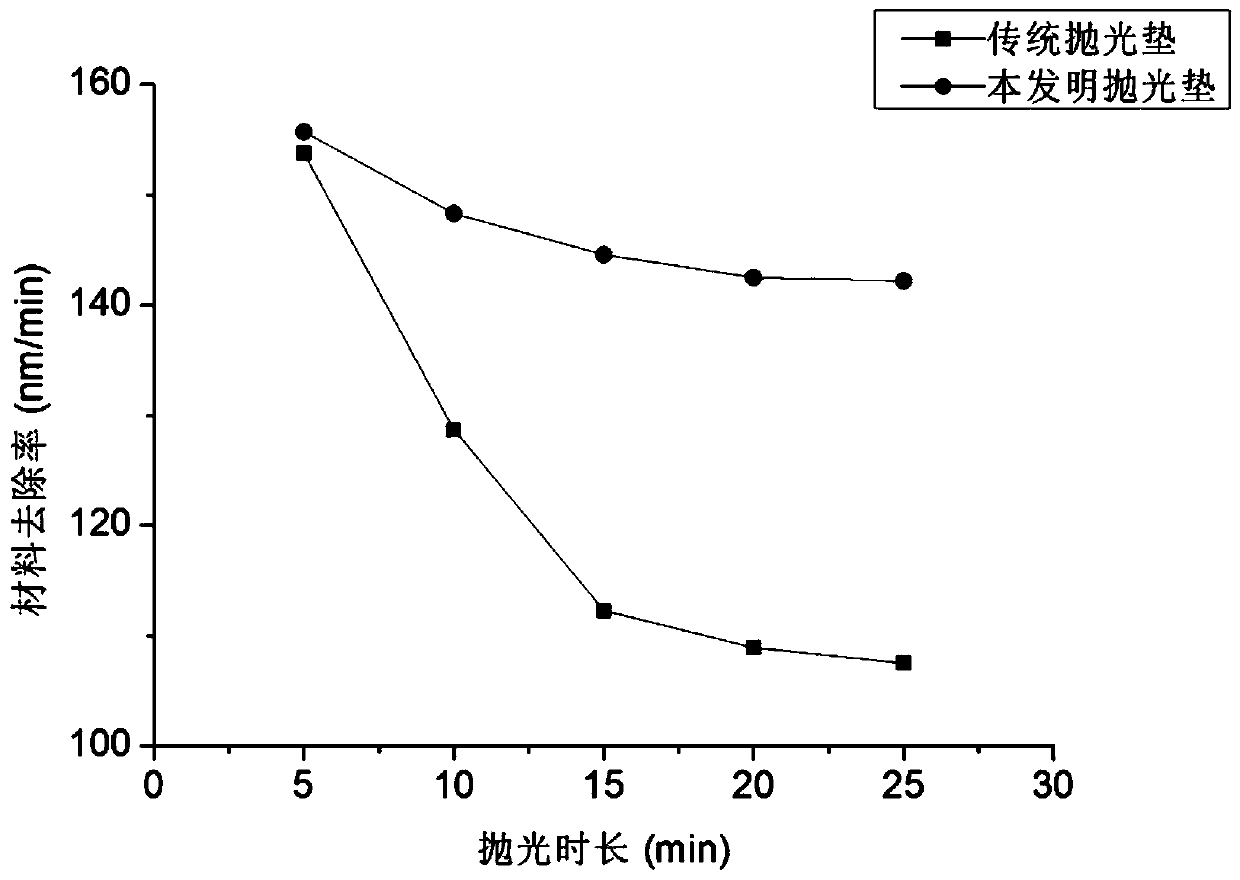

A polishing pad and fast technology, applied in the direction of grinding tools, etc., can solve the problems of scrap scratches and difficult discharge of scrap, and achieve the effect of reducing resistance, good drag reduction effect, and good chip removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

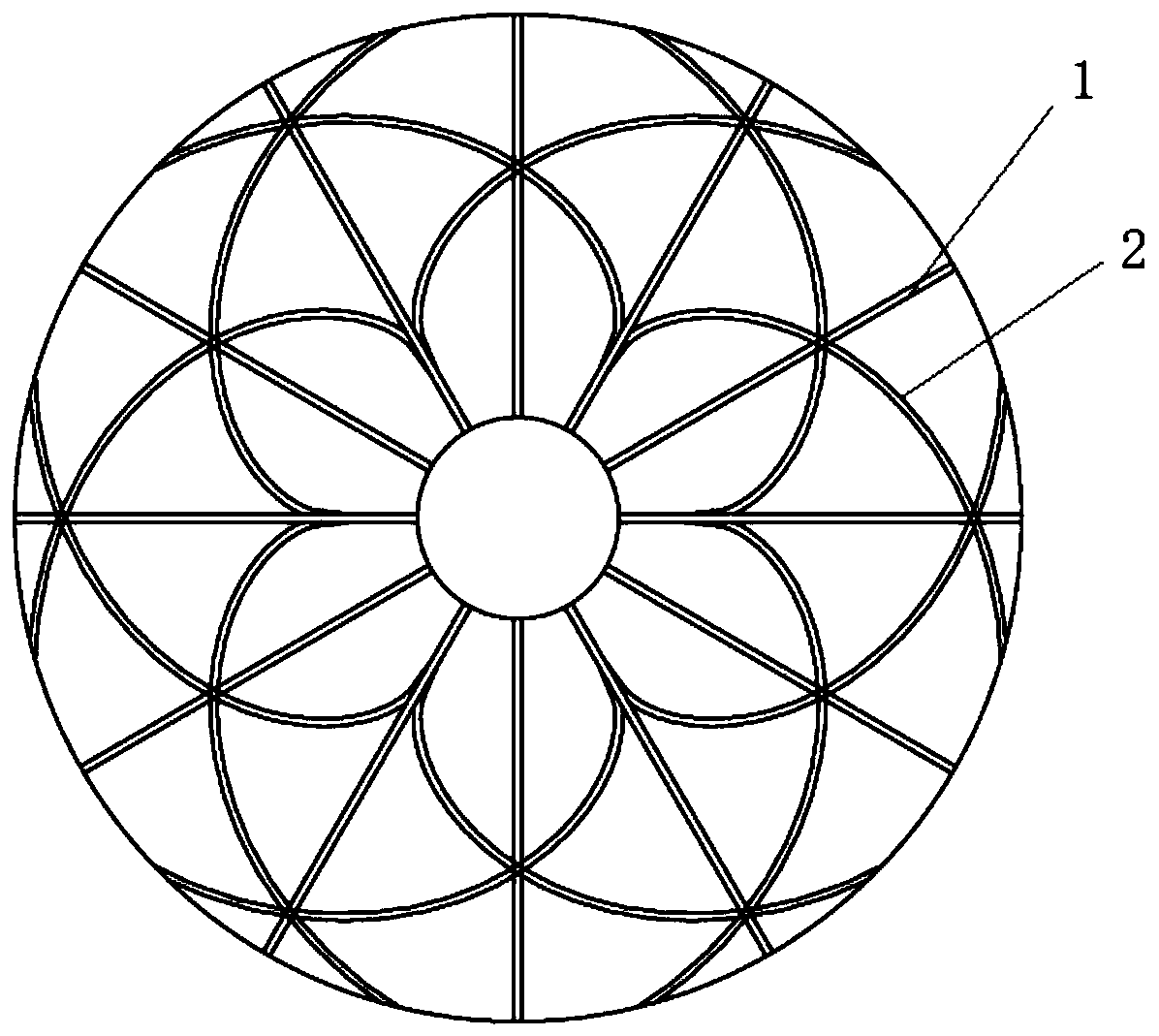

[0032] Such as figure 1 As shown, the present embodiment provides a fast chip removal polishing pad, which includes a main chip removal groove 1 and a secondary chip removal groove 2, the main chip removal groove 1 is composed of 10-14 divergent grooves, All divergent grooves are centered on the center of the polishing pad and distributed on the surface of the polishing pad at an equal angle;

[0033] The auxiliary chip removal groove 2 is composed of 10-14 spiral grooves, and each spiral groove is centered on the center of the polishing pad and distributed equiangularly on the surface of the polishing pad.

[0034] The present invention utilizes the centrifugal force generated by the rotation during the polishing process to the greatest extent through the divergent main chip removal groove, so that the waste chips generated during processing leave the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com