U-shaped flame reciprocating heating trolley-type heat treatment device and treatment method thereof

A trolley-shaped, U-shaped technology, used in heat treatment equipment, heat treatment furnaces, furnaces, etc., can solve the problems of unsatisfactory heat treatment process requirements, unfavorable flame propagation, poor thermal conductivity, etc. Dynamic heat load adjustment, the effect of ensuring quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

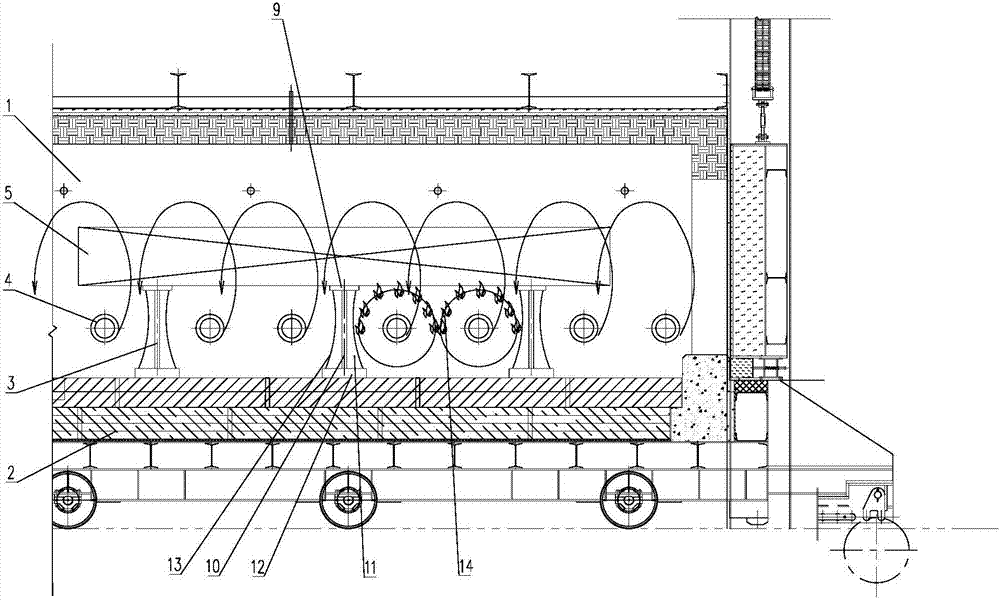

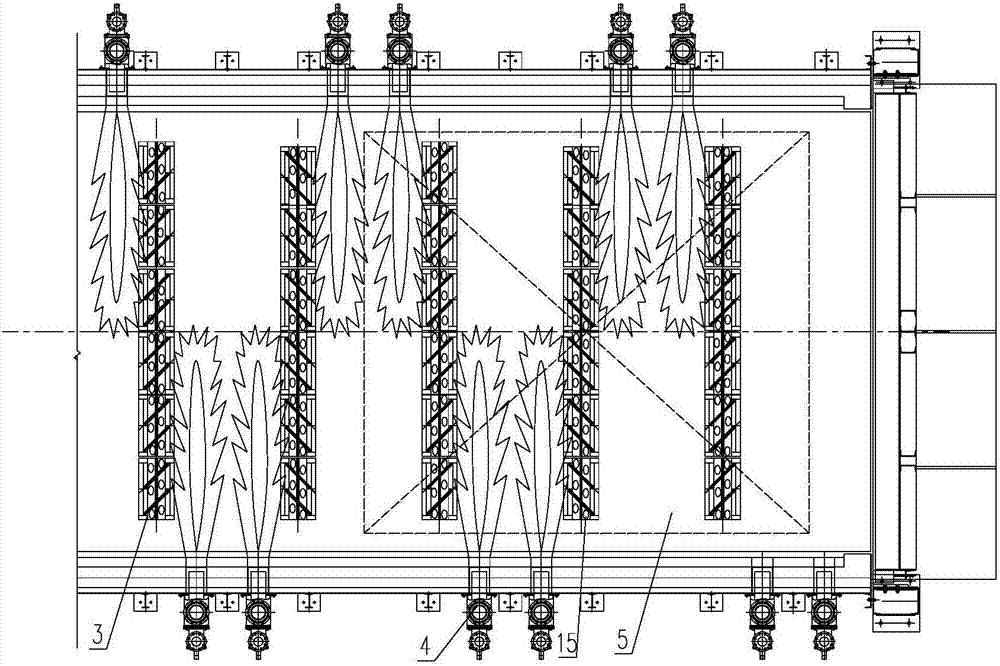

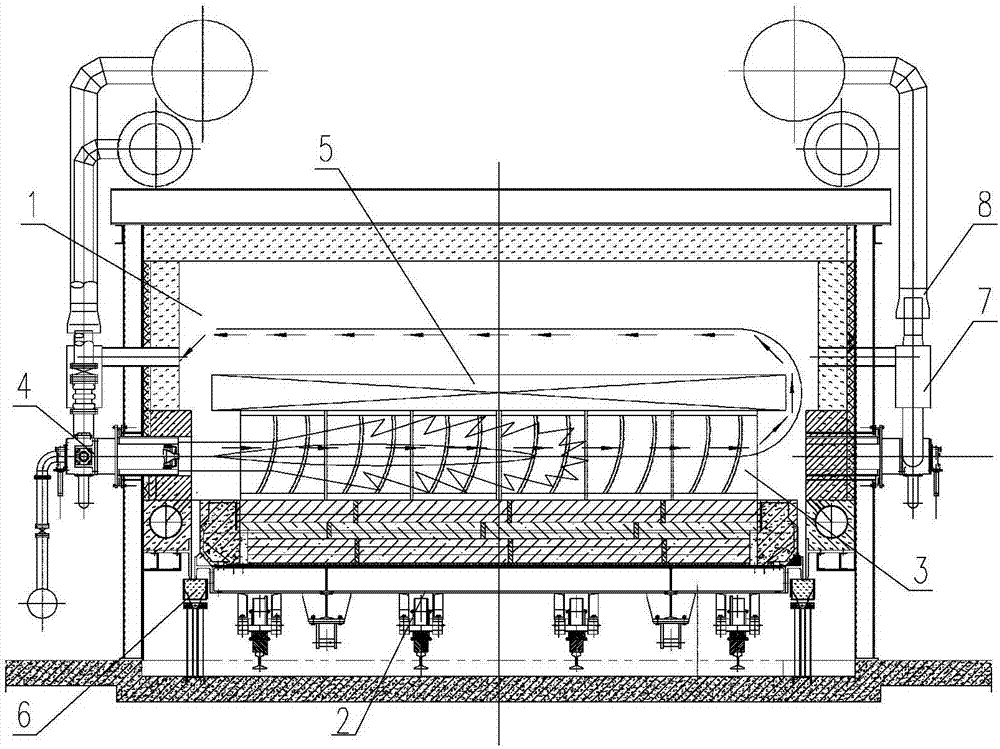

[0040] Such as figure 1 , figure 2 , image 3 As shown, a U-shaped flame reciprocating heating trolley-type heat treatment equipment includes a furnace body 1, a furnace car 2, a pad iron 3, a burner 4, a workpiece 5, a sealing system 6, an air supply system 7, and a smoke exhaust system 8. And its auxiliary loading and discharging positioning system, electric drive and instrument automation system and video transmission system. The burner 4 is connected to the air supply system 7 and the smoke exhaust system 8 through pipelines.

[0041] Multiple horns 3 are arranged in a row, and the multiple rows of horns 3 are placed parallel to each other on the furnace cart 2. The burners 4 are staggered and fixed on both sides of the furnace wall of the furnace body 1, and the burner 4 is located between the multiple rows of horns In the gap; the burner 4 and the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com