Novel furnace top cooling device for oxygen-enriched side copper blowing smelting furnace

A copper smelting furnace and cooling device technology, applied in electric furnaces, crucible furnaces, rotary drum furnaces, etc., can solve the problems such as nodules at the secondary tuyere affecting production, low temperature at the upper part of the furnace body, unfavorable smelting reactions, etc., and achieve convenient installation. and maintenance, increase residence time, and improve the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

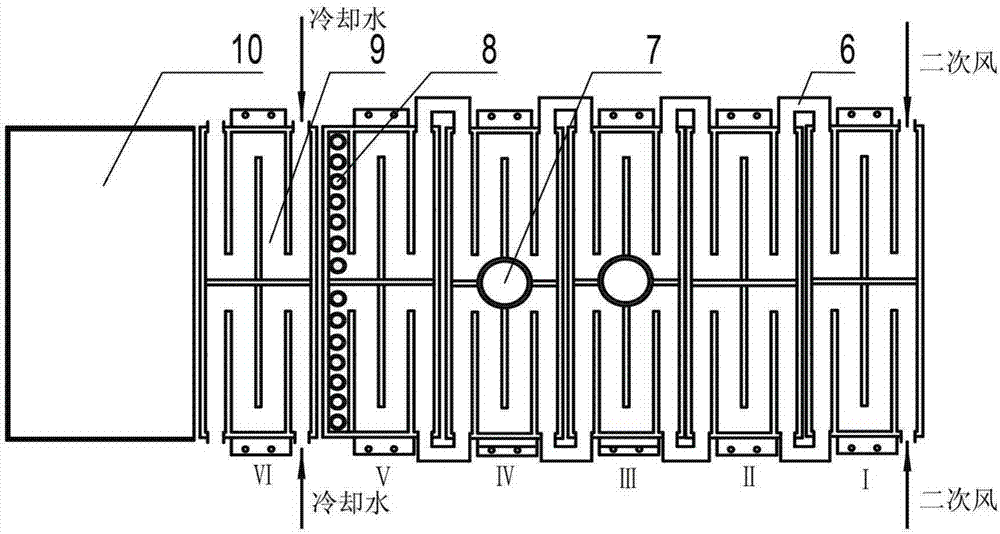

[0021] The size of the device can be adjusted according to the roof shape of different oxygen-enriched side-blown furnaces. The following are examples of specific implementation cases:

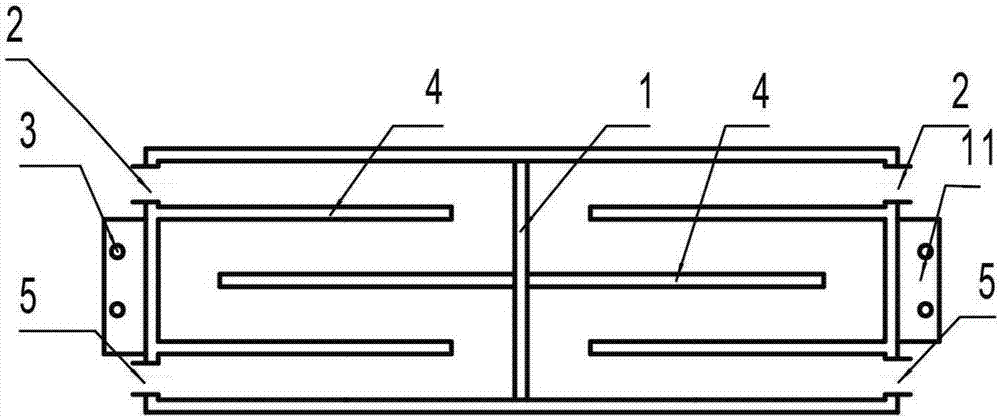

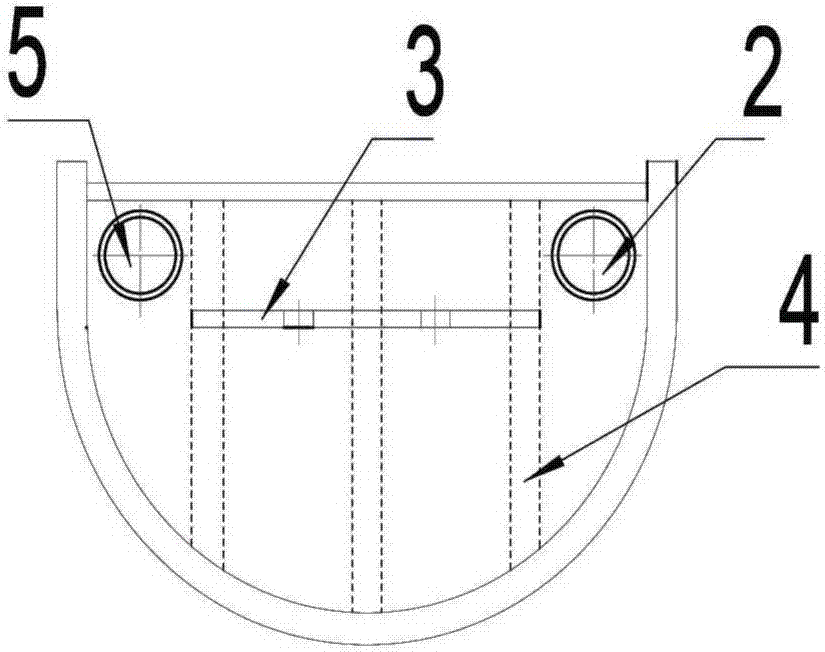

[0022] The present invention is applied to the roof of an oxygen-enriched side-blown copper smelting furnace with a length of 9.4m and a width of 2.8m. The length and width of the flue inlet 10 are both 2.8m. The area to be covered by the furnace roof is 6.6m in length and 2.8m in width. The length of each single air-cooled cooling wall is 3.2m, the width is 1.1m, the diameter of the lower semicircular section is 1.1m, and the height of the upper extension is 0.37m; The fixed plate 11 is used to be connected to the water jacket of the furnace body, and a fixed bolt port 3 is left on the fixed plate 11, which is used for fixing the air-cooled stave and preventing the air-cooled stave from moving.

[0023] Among them, 5 air-cooled staves in No. Ⅰ~Ⅴ are cooled by air, and the structure and size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com