Corrugated moving electrode capacitive pressure sensor

A technology of pressure sensor and moving electrode, which is applied in the direction of measuring fluid pressure through electromagnetic components, measuring fluid pressure, instruments, etc. It can solve the problems of parasitic capacitance and edge effects affecting measurement stability, affecting vacuum degree, and easy gas adhesion, etc., to achieve Large relative displacement, reliable use and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

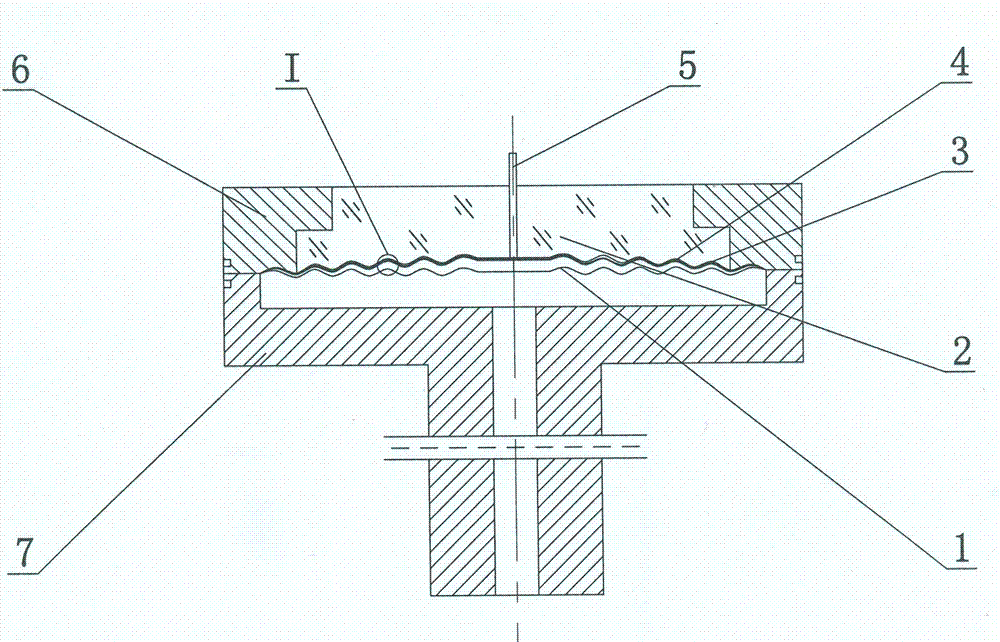

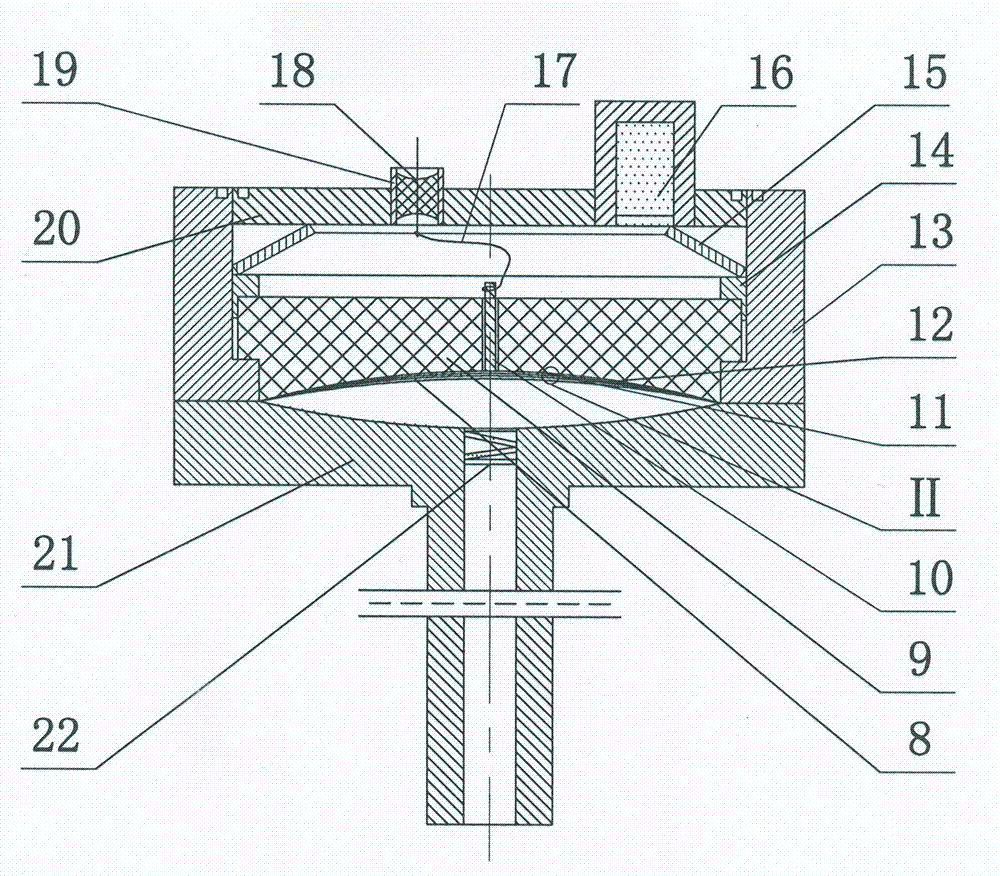

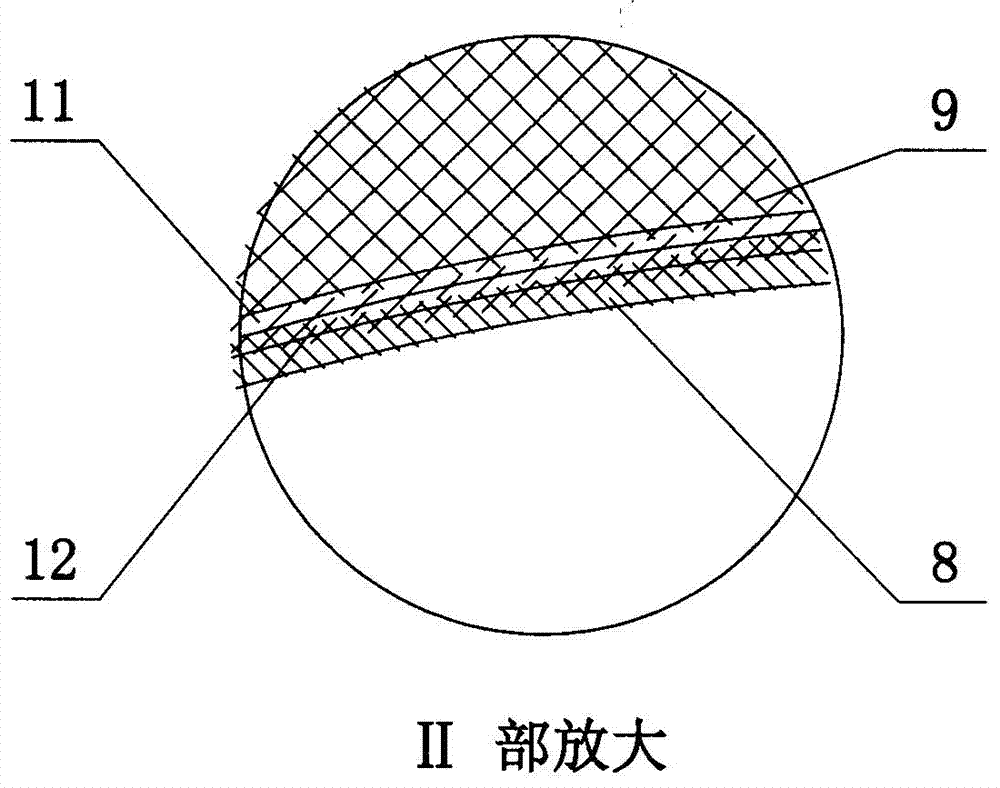

[0015] according to Figure 1~4 The specific structure of the present invention will be described in detail. The capacitive pressure sensor with a corrugated moving electrode includes a casing, a fixed electrode insulator 2 , an outer electrode 5 and a moving electrode assembled in the casing. The shell is composed of a constant elastic support sleeve 6 which is matched with a fixed electrode insulator 2 and a support seat 7 with a pressure introduction port. The moving electrode adopts the constant elastic corrugated moving electrode 1 made of corrugated elastic diaphragm, and the corrugated moving electrode 1 is clamped and pressed by the constant elastic supporting sleeve 6 and the supporting seat 7, and the constant elastic supporting sleeve 6 and the supporting seat 7 are clamped and pressed. and the corrugated movable electrode 1 are fixedly connected together. The constant elastic support sleeve 6 that is matched with the fixed electrode insulator 2 and the support se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com