Method for recycling lithium in waste lithium battery slags through chloridizing roasting and evaporation

A technology of chlorination roasting and lithium battery, which is applied in the direction of improving process efficiency, can solve the problem of no subsequent treatment of lithium slag, and achieve the effect of low price, simple operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

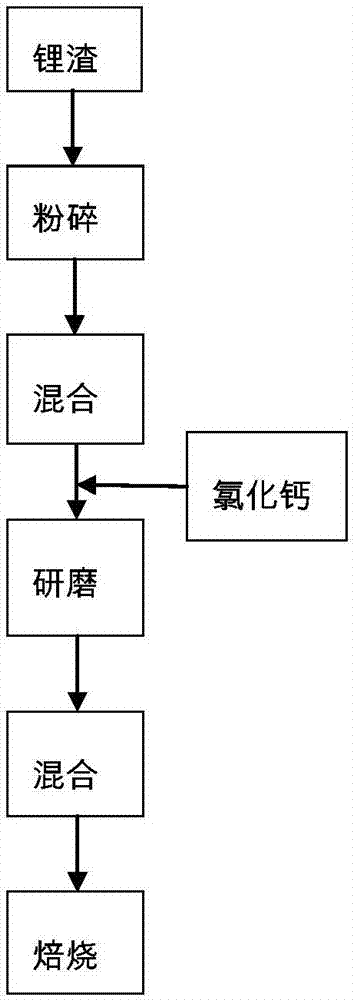

Method used

Image

Examples

Embodiment 1

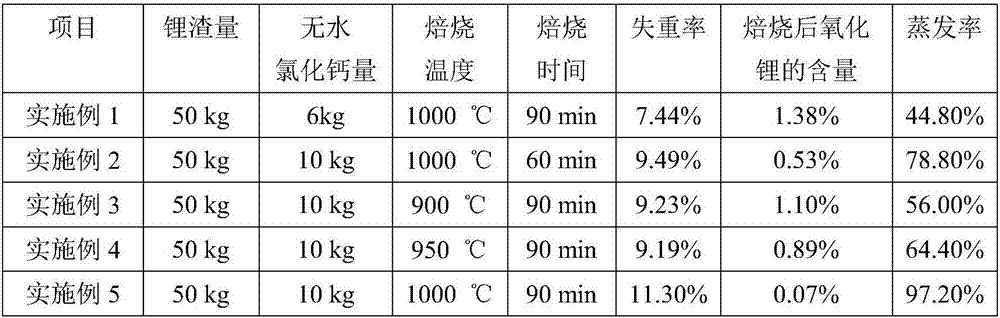

[0028] Example 1: Lithium in scrap lithium battery slag treated by chlorination, roasting, evaporation and recovery by pyrolysis

[0029] (1) Pulverizing: take by weighing 50kg of scrap lithium battery slag, then pulverize the massive lithium slag;

[0030] (2) Mixing: grinding again after mixing the crushed lithium slag with 6kg of calcium chloride;

[0031] (3) Roasting: Roast the mixed powder of lithium slag and calcium chloride in a high-temperature muffle furnace at 1000°C for 90 minutes

Embodiment 2

[0032] Example 2: Lithium in scrap lithium battery slag treated by chlorination roasting evaporation recovery fire method

[0033] (1) Grinding: take by weighing 50kg of scrap lithium battery slag, then pulverize the massive lithium slag;

[0034] (2) mixing: grinding again after mixing the crushed lithium slag with 10kg of calcium chloride;

[0035] (3) Roasting: Roast the mixed powder of lithium slag and calcium chloride in a high-temperature muffle furnace at 1000° C. for 60 minutes to evaporate the lithium in the lithium slag.

Embodiment 3

[0036] Example 3: Lithium in scrap lithium battery slag treated by chlorination, roasting, evaporation and recovery by pyrolysis

[0037] (1) Grinding: take by weighing 50kg of scrap lithium battery slag, then pulverize the massive lithium slag;

[0038] (2) mixing: grinding again after mixing the crushed lithium slag with 10kg of calcium chloride;

[0039] (3) Roasting: The mixed powder of lithium slag and calcium chloride is roasted in a high-temperature muffle furnace at 900° C. for 90 minutes to evaporate the lithium in the lithium slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com