Preparation method of high-capacity ternary positive electrode material and battery

A positive electrode material and high-capacity technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high residual lithium on the surface, poor batch quality, slow development and research, etc., and achieve uniform secondary particle size, low Effects of residual lithium, pH value, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a high-capacity ternary positive electrode material, comprising the following steps:

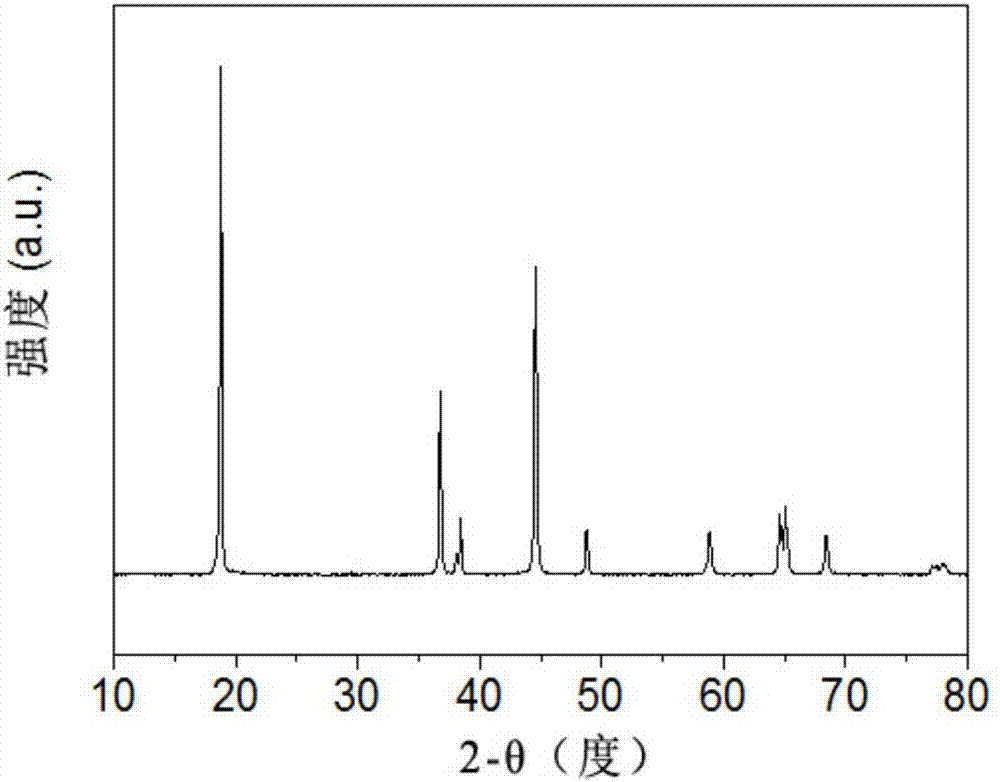

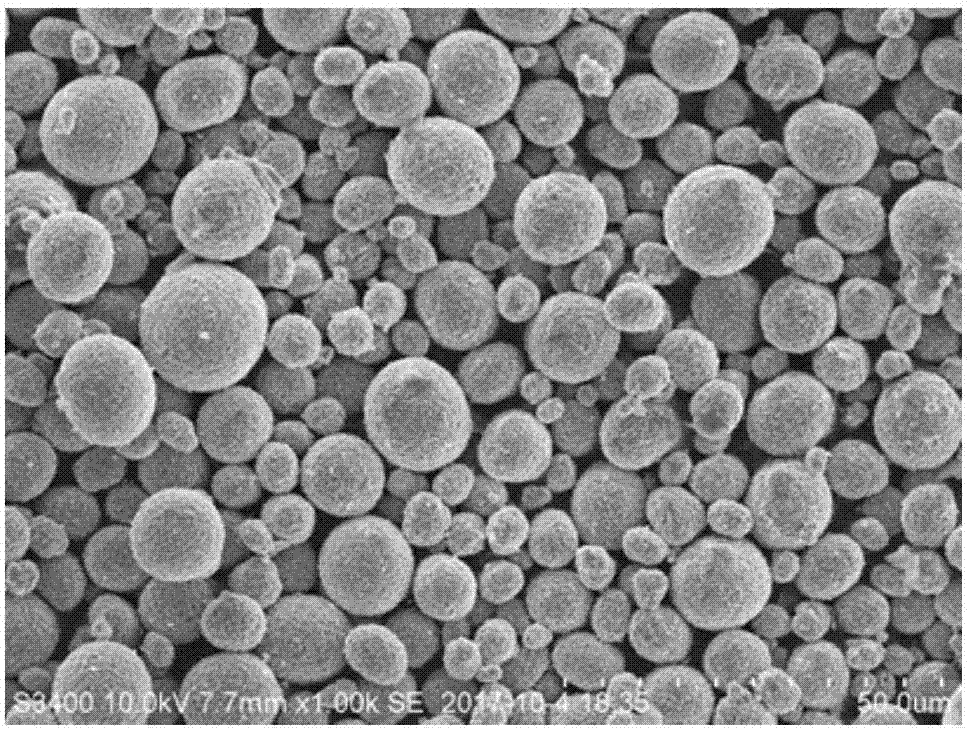

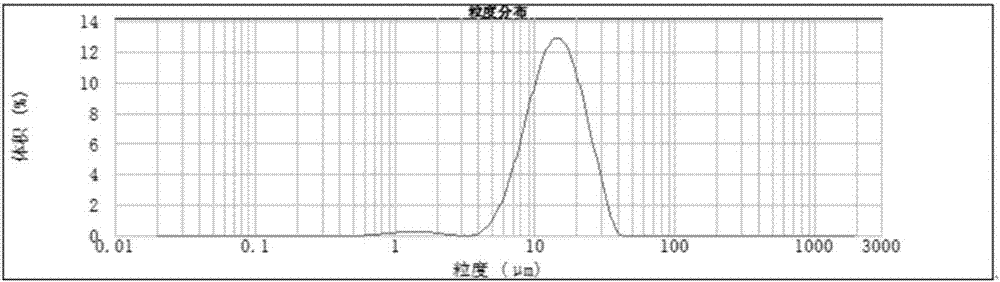

[0042] 1) NiSO 4 、CoSO 4 and NaAlO 2 Mole ratio to Ni 2+ :Co 2+ :Al 3+ = 0.815:0.15:0.035 ratio mixed, dissolved in pure water, and configured as a metal ion solution with a total concentration of 2mol / L. The above-mentioned metal ion solution and 4mol / L sodium hydroxide solution are simultaneously injected into the reaction kettle with 4mol / L ammonia water as the bottom liquid through a peristaltic pump, and the pH of the reaction is controlled to be 10-12 and the temperature is 30-60°C; After filtering and washing, drying under vacuum at 120 °C to obtain the nickel cobalt aluminum hydroxide precursor Ni 0.815 co 0.15 Al 0.035 (OH) 2 ; Mix 640.11g nickel-cobalt-aluminum hydroxide precursor with 300g lithium hydroxide in a high-speed mixer for 15min, then mix the resulting mixture in an oxygen flow rate of 18m 3 After calcination at 750°C for 15 hours ...

Embodiment 2

[0051] A method for preparing a high-capacity ternary positive electrode material, comprising the following steps:

[0052] 1) NiSO 4 、CoSO 4 and NaAlO 2 Mole ratio to Ni 2+ :Co 2+ :Al 3+ =0.88:0.09:0.03 ratio mixed, dissolved with pure water, configured as a metal ion solution with a total concentration of 2mol / L, the above-mentioned metal ion solution and 4mol / L sodium hydroxide solution were injected into the solution at a rate of 4mol / L by a peristaltic pump simultaneously. In the reaction kettle with L ammonia water as the bottom liquid, the pH of the reaction is controlled to be 10-12, and the temperature is 30-60°C. After filtering and washing, dry under vacuum at 120°C to obtain the hydroxide precursor Ni 0.88 co 0.09 Al 0.03 (OH) 2 ; Mix 645.81g nickel-cobalt-aluminum hydroxide precursor with 300g lithium hydroxide in a high-speed mixer for 15min, and then mix the mixture at an oxygen flow rate of 18m 3 Calcined at 740°C for 15 hours in a muffle furnace per h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com