Preparation method of 1-fluorine-disulfonic anhydride

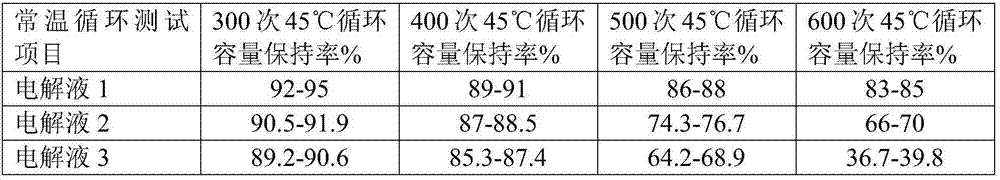

A technology of ethanedisulfonic anhydride and ethanedisulfonic acid, which is applied in the field of preparation of 1-fluoro-ethanedisulfonic anhydride and 1-fluoro-ethanedisulfonic anhydride, can solve unfavorable mass production, green environmental protection concept, and equipment investment Large, high energy consumption and other issues, to achieve the effect of improving charge and discharge performance and cycle times, small equipment investment, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

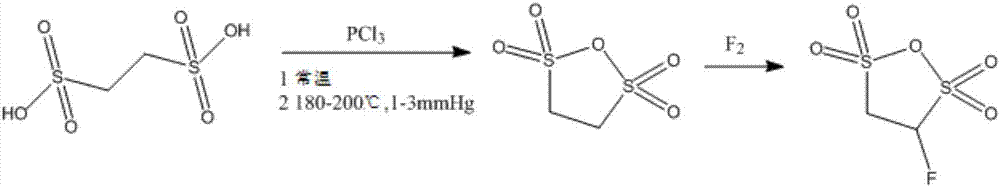

[0021] Take 0.1mol (19g) of ethanedisulfonic acid, add molecular sieves, add 76g of phosphorus trichloride and react at room temperature for 5 hours, then raise the temperature to 180°C, continue to react for 3 hours under a vacuum of 1-3mmHg, and then extract with dichloromethane, Crystallization, to obtain 17g ethanedisulfonic anhydride, the yield is 98.8%;

[0022] Pass fluorine gas into the ethanedisulfonic anhydride obtained above, control the molar ratio of ethanedisulfonic anhydride and fluorine gas to 1:0.8, and prepare 18.25g of 1-fluoro-ethanedisulfonic anhydride (CAS1234622-61-7). The rate is 97.2%. The total yield was calculated to be 96.03%.

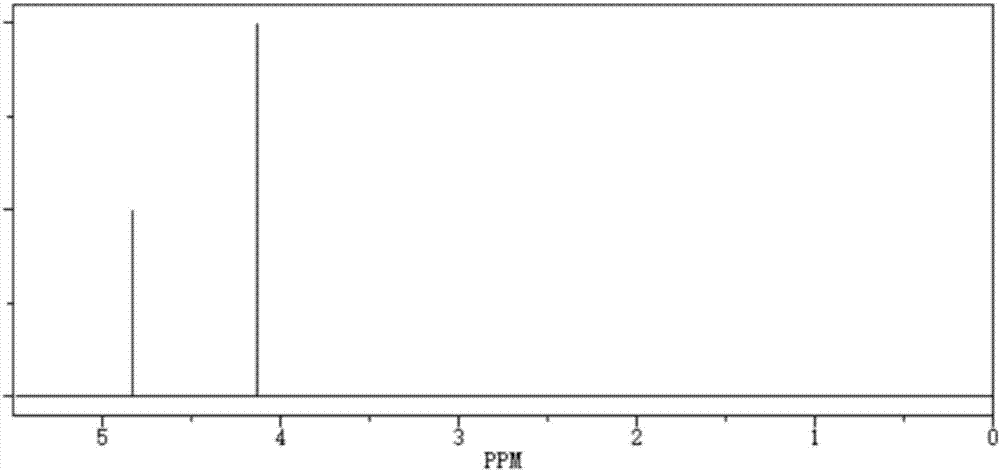

[0023] The purity of the obtained 1-fluoro-ethanedisulfonic anhydride is 99.8%, the boiling point is 338.6°C, 760mmHg, 1.99g / cm 3 , the impurity content of ethanedisulfonic acid and 1,2-difluoroethanedisulfonic anhydride is detected to be less than 1ppm, and the 1H NMR spectrum is as follows figure 1 shown.

Embodiment 2

[0025] Take 0.1mol (19g) of ethanedisulfonic acid, add molecular sieves, add 57g of phosphorus trichloride and react at room temperature for 8 hours, then raise the temperature to 200°C, continue to react for 5 hours under a vacuum of 1-3mmHg, and then extract with dichloromethane, Crystallization, to obtain 16.77g ethanedisulfonic anhydride, the yield is 97.5%;

[0026] Fluorine gas was passed into the ethanedisulfonic anhydride obtained above, and the molar ratio of ethanedisulfonic anhydride to fluorine gas was controlled to be 1:0.5, and 17.84 g of 1-fluoro-ethanedisulfonic anhydride was prepared with a yield of 96.3%. The calculated total yield was 93.89%.

[0027] The purity of the obtained 1-fluoro-ethanedisulfonic anhydride is 99.6%, the boiling point is 337.8°C, 760mmHg, 2.01g / cm 3 , The impurity content of ethanedisulfonic acid and 1,2-difluoroethanedisulfonic anhydride was detected to be less than 1ppm.

Embodiment 3

[0029] Take 0.1mol (19g) of ethanedisulfonic acid, add molecular sieves, add 95g of phosphorus trichloride and react at room temperature for 6 hours, then raise the temperature to 190°C, continue to react for 2 hours under a vacuum of 1-3mmHg, and then extract with dichloromethane, Crystallization, to obtain 16.9g ethanedisulfonic anhydride, the yield is 98.25%;

[0030] Fluorine gas was passed into the ethanedisulfonic anhydride obtained above, and the molar ratio of ethanedisulfonic anhydride to fluorine gas was controlled to be 1:0.7 to prepare 18.07 g of 1-fluoro-ethanedisulfonic anhydride with a yield of 96.79%. The total yield was calculated to be 95.1%.

[0031] The purity of the obtained 1-fluoro-ethanedisulfonic anhydride is 99.7%, the boiling point is 338.4°C, 760mmHg, 1.98g / cm 3 , The impurity content of ethanedisulfonic acid and 1,2-difluoroethanedisulfonic anhydride was detected to be less than 1ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com